Automatic feeding equipment for pig farm

An automatic technology for pig farms, applied in animal feeding devices, applications, animal drinking water devices, etc., can solve the problem of not being able to effectively increase the feeding frequency of live pigs, the meat yield of fattening pigs, the conditioned reflex of pigs that are difficult to form a diet, and the increase in work Repeatability and other issues, to achieve the effect of a wide range of food, improve mobility, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

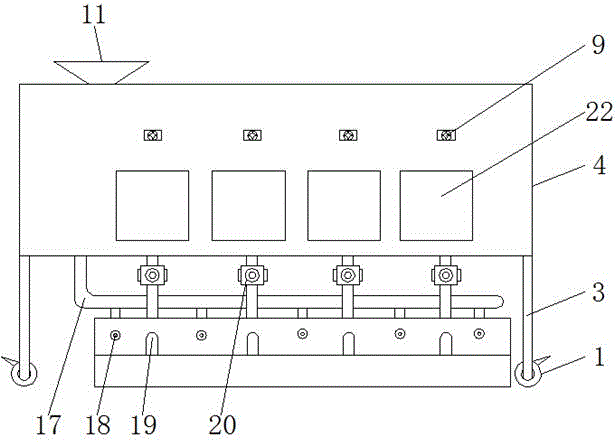

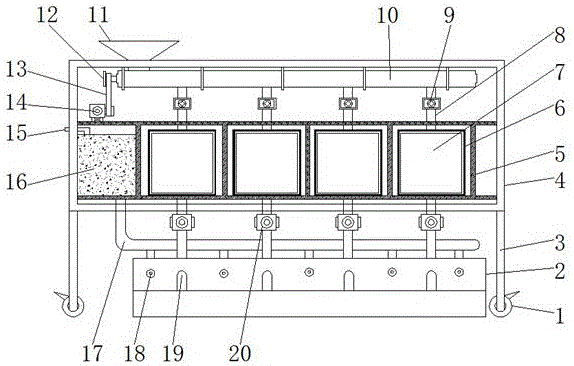

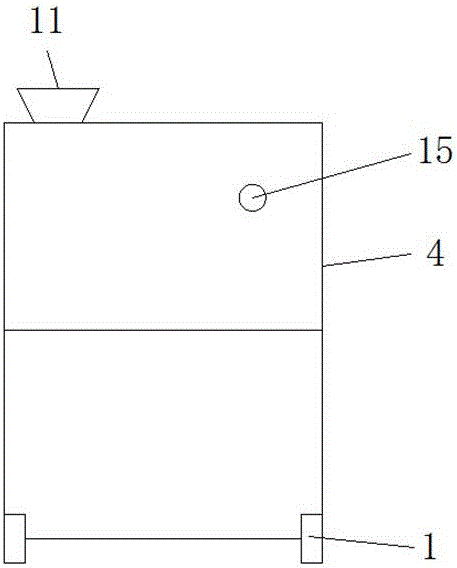

[0019] Specific implementation method: After moving the equipment to the place of use, turn on the brake device of the walking wheel 1, connect the water injection port 15 on one side of the housing 4 through a pipeline, inject the water source for pigs into the water storage tank 16, and fill it with pigs' drinking water. Power on the equipment, pour feed for live pigs into the feeding hopper 11, at this time the motor 14 starts to work, the feed enters the inside of the screw feeding device 10 from the feeding hopper 11 through the pipeline, and the motor 14 drives the screw feeding device 12 to rotate through the belt 13 , open switch valve 9 now, and screw feeder 12 begins to distribute material evenly in feed storage box 6, whether the feed in feed storage box 6 is observed through observation window 22 during material distribution, if full, then close switch valve 9, At the same time, whether the feed in the feed storage box 6 can be observed through the observation windo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com