Movable jaw crusher

A jaw crusher and feeder technology, applied in grain processing and other directions, can solve the problems of long equipment assembly time, affecting mining progress, inconvenient equipment movement, etc., achieving the effect of small vibration, ensuring mining progress, and moving freely.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

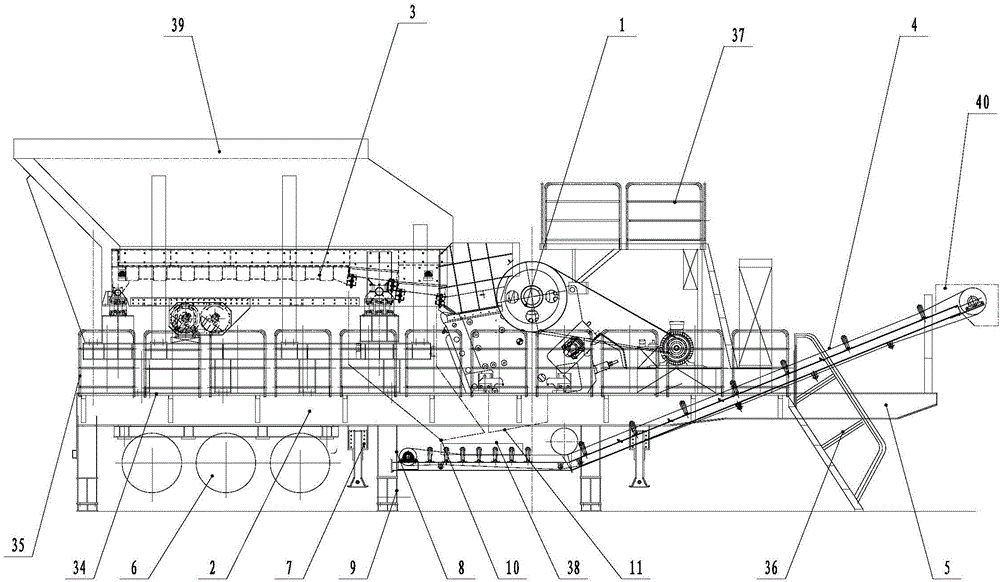

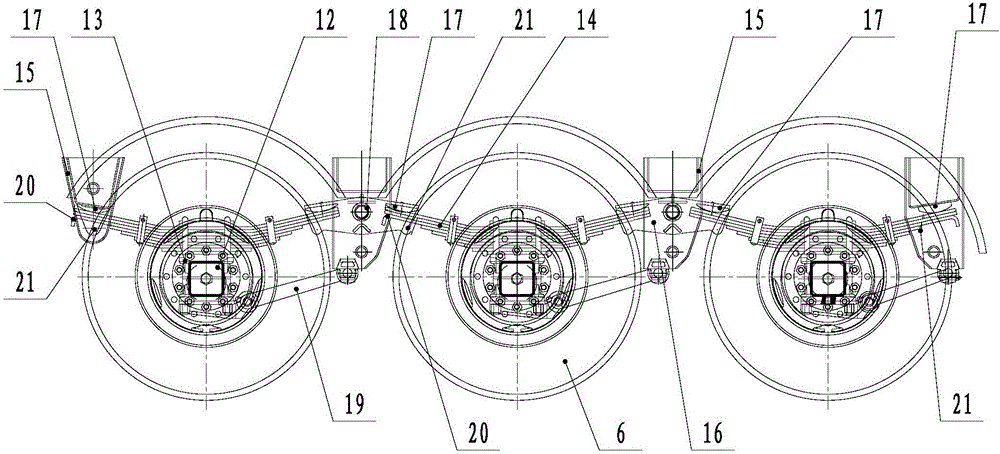

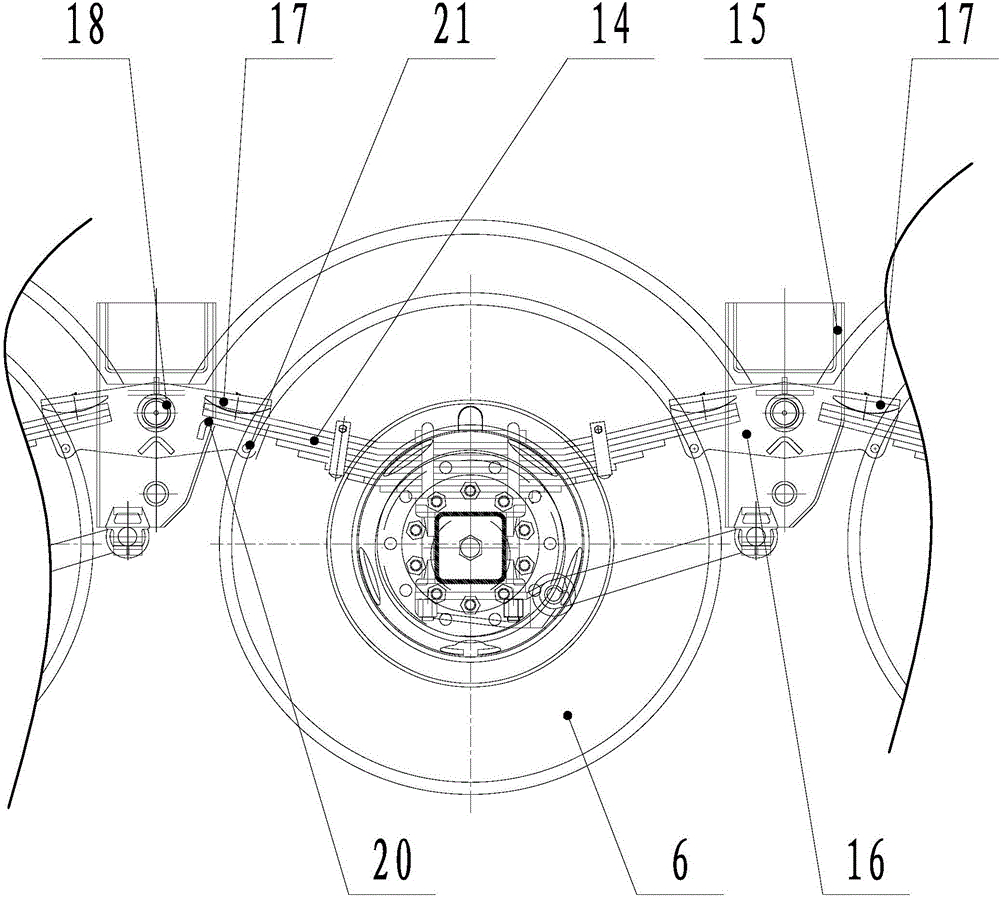

[0025] Embodiment: a kind of mobile jaw crusher (see attached Figures 1 to 5), including jaw crusher body 1, vehicle frame 2, feeder 3, conveying mechanism 4, traction seat 5 is provided at the front end of the vehicle frame, several wheels 6 are installed on the vehicle frame, and three supporting shafts 12 are installed on the vehicle frame The wheels are rotatably connected to the two ends of the support shaft, and two wheels are installed at the two ends of each support shaft. Both ends of the support shaft are fastened with mounting bases 13, and the mounting bases are connected with leaf springs 14. Eight connecting bases 15 are fastened on the vehicle frame, four are respectively arranged on the left and right sides of the vehicle frame, and the ends of the support shafts are respectively It is arranged between two adjacent connecting seats, and the connecting seat between two adjacent wheels is rotatably connected with a transmission plate 16, and a torsion spring 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com