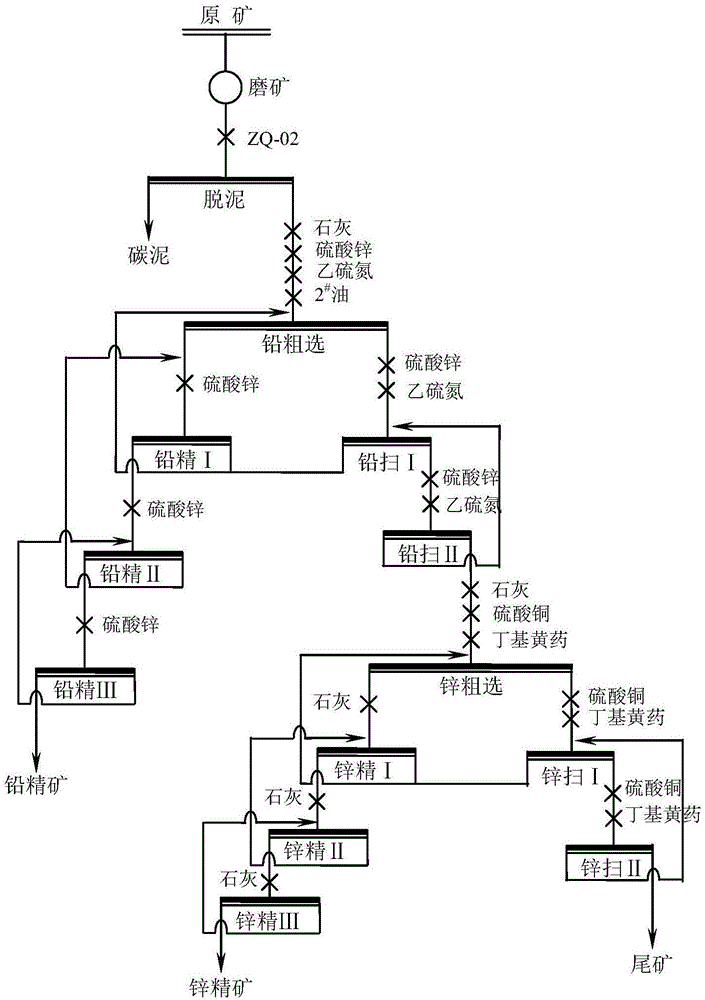

Low-grade phyllite type lead zinc ore beneficiation method

A beneficiation method and phyllite technology, which is applied in the beneficiation field of low-grade phyllite-type lead-zinc ore, can solve the problems of low comprehensive recovery index, poor flotation effect, and low separation efficiency, so as to reduce the cost of beneficiation, Improve the effect and improve the effect of the comprehensive recovery index of lead and zinc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Mix 60g of kerosene, 150g of 1,1-diisopropylmethanol, 100g of 2-ethylbutanol, and 50g of 1,1-dimethylbenzyl alcohol, and stir in a beaker at room temperature and pressure with a magnetic stirrer for 30- 40min to get desliming agent ZQ-02.

Embodiment 2

[0037] Mix 80g of kerosene, 150g of 1,1-diisopropylmethanol, 100g of 2-ethylbutanol, and 50g of 1,1-dimethylbenzyl alcohol, and stir for 30~ 40min to get desliming agent ZQ-02.

Embodiment 3

[0039] Mix 50g of kerosene, 150g of 1,1-diisopropylmethanol, 100g of 2-ethylbutanol, and 50g of 1,1-dimethylbenzyl alcohol, and stir with a beaker as a container under normal temperature and pressure, and a magnetic stirrer for 30~ 40min to get desliming agent ZQ-02.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com