Manual sugarcane peeling and cleaning device with feeding, recovery and cutting assembly

A cleaning device, manual technology, applied in liquid cleaning methods, cleaning methods and utensils, metal processing, etc., can solve problems such as broken mouth, impractical, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

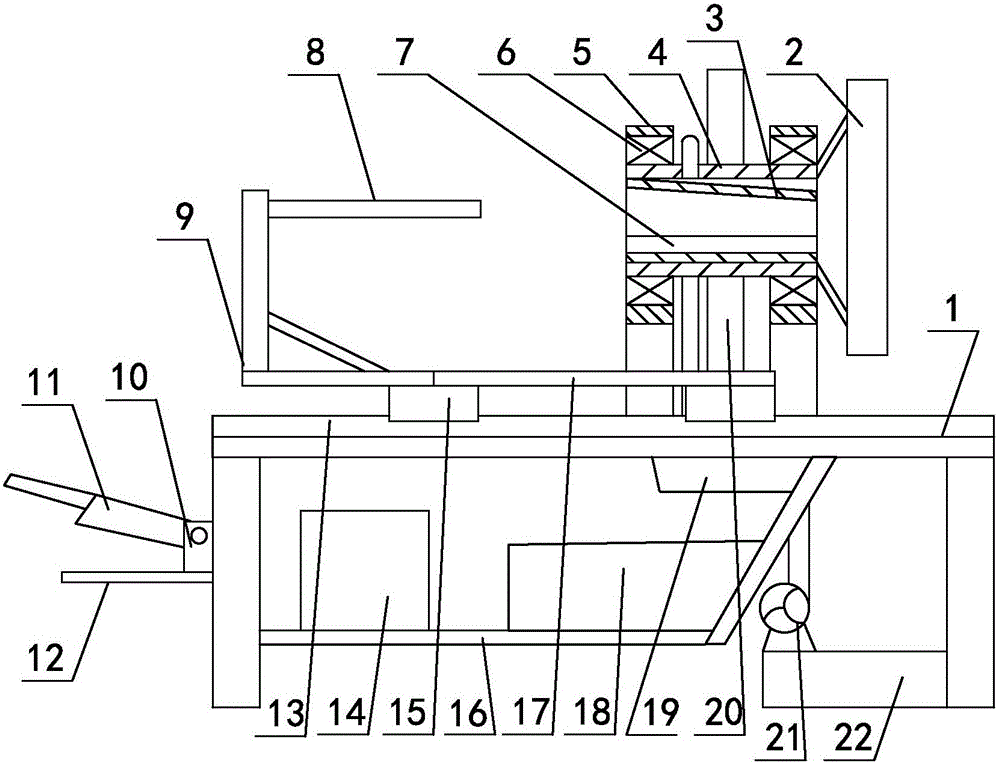

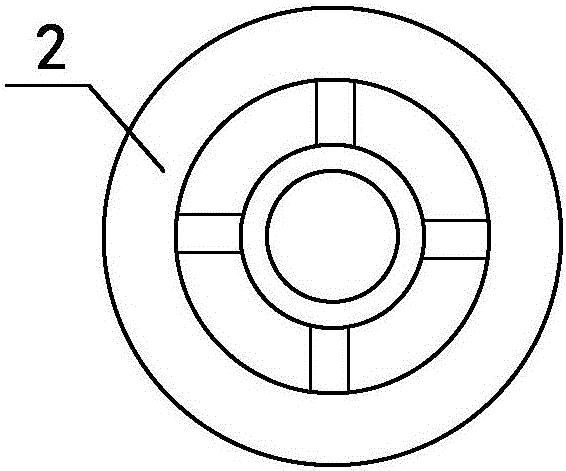

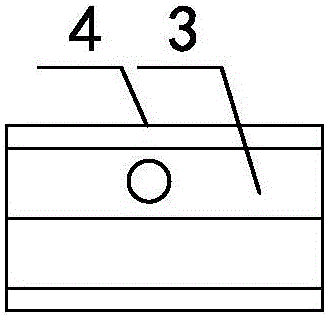

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the manual sugarcane peeling and cleaning device with feeding, recovery and cutting components includes a workbench 1 and an adjustment plate 7, and two left and right parallel bearing seats 5 are arranged on the workbench 1, corresponding to two The bearing seat 5 is horizontally provided with a scraper cover 4, and the left and right ends of the scraper cover 4 communicate with the outside world. On the inner top wall of the scraper cover 4, a blade 3 with a high left and a low right is horizontally arranged. 4 The direction of rotation is tangent, and the corresponding blade 3 is provided with a discharge port on the scraper cover 4, and the two ends of the scraper cover 4 are respectively installed on the corresponding bearing housing 5 through the bearing 6, and a scraper for scraping is fixed on the right end of the scraper cover 4. The handle plate 2 that the holster 4 rotates, the middle part of th...

Embodiment 2

[0027] On the basis of the first embodiment, the inclination angle of the blade 3 is changed to 15 degrees; the inner diameter of the scraper sheath 4 is changed to 60 mm.

[0028] Others are the same as embodiment one.

Embodiment 3

[0030] On the basis of the first embodiment, the inclination angle of the blade 3 is changed to 10 degrees; the inner diameter of the scraper sheath 4 is changed to 40mm.

[0031] Others are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com