Manufacturing method for mold internal decoration molding of vehicle-mounted center control integrated plastic curved surface panel

A manufacturing method and panel mold technology, applied in coating and other directions, can solve problems such as immaturity, and achieve the effect of meeting the needs of assembly, good customer experience, and high comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The manufacturing method for the in-mold decoration molding of the vehicle-mounted central control integrated plastic panel of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

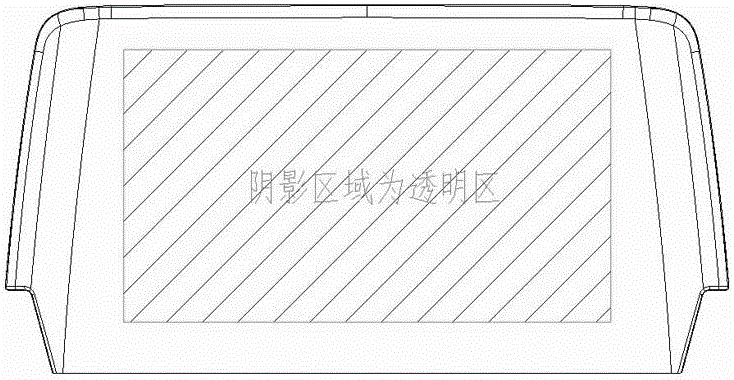

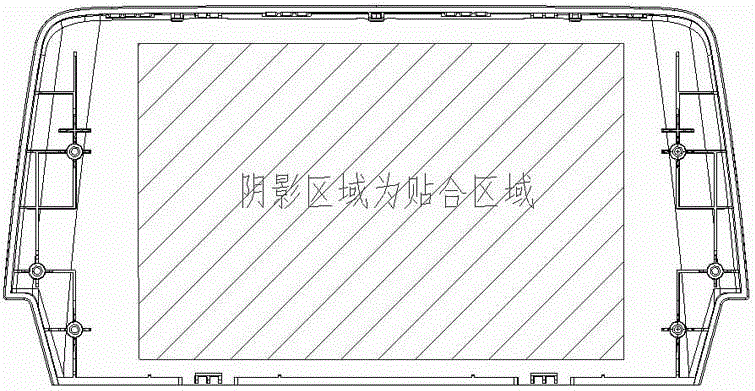

[0018] See figure 1 and figure 2 , a manufacturing method for in-mold decoration molding of a vehicle-mounted central control integrated plastic panel, which includes the following steps:

[0019] A method for manufacturing in-mold decoration molding of a plastic curved surface panel integrated with a vehicle-mounted central control, characterized in that it includes the following steps:

[0020] Step 1. Prepare a car-grade transparent film diaphragm, cut it and remove dust;

[0021] Step 2. Evenly soak a layer of car-grade transparent paint on the surface of the diaphragm in step 1 to strengthen the hardness of the diaphragm (3H / 750g) and take into account anti-reflection, anti-fingerprint and anti-glare funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com