Biomass briquette and preparation method thereof

A technology for biomass and briquette, applied in the field of clean coal, can solve the problems of imperfect process technology and insufficient utilization of waste, and achieve the effects of high level of clean production, reliable sources and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

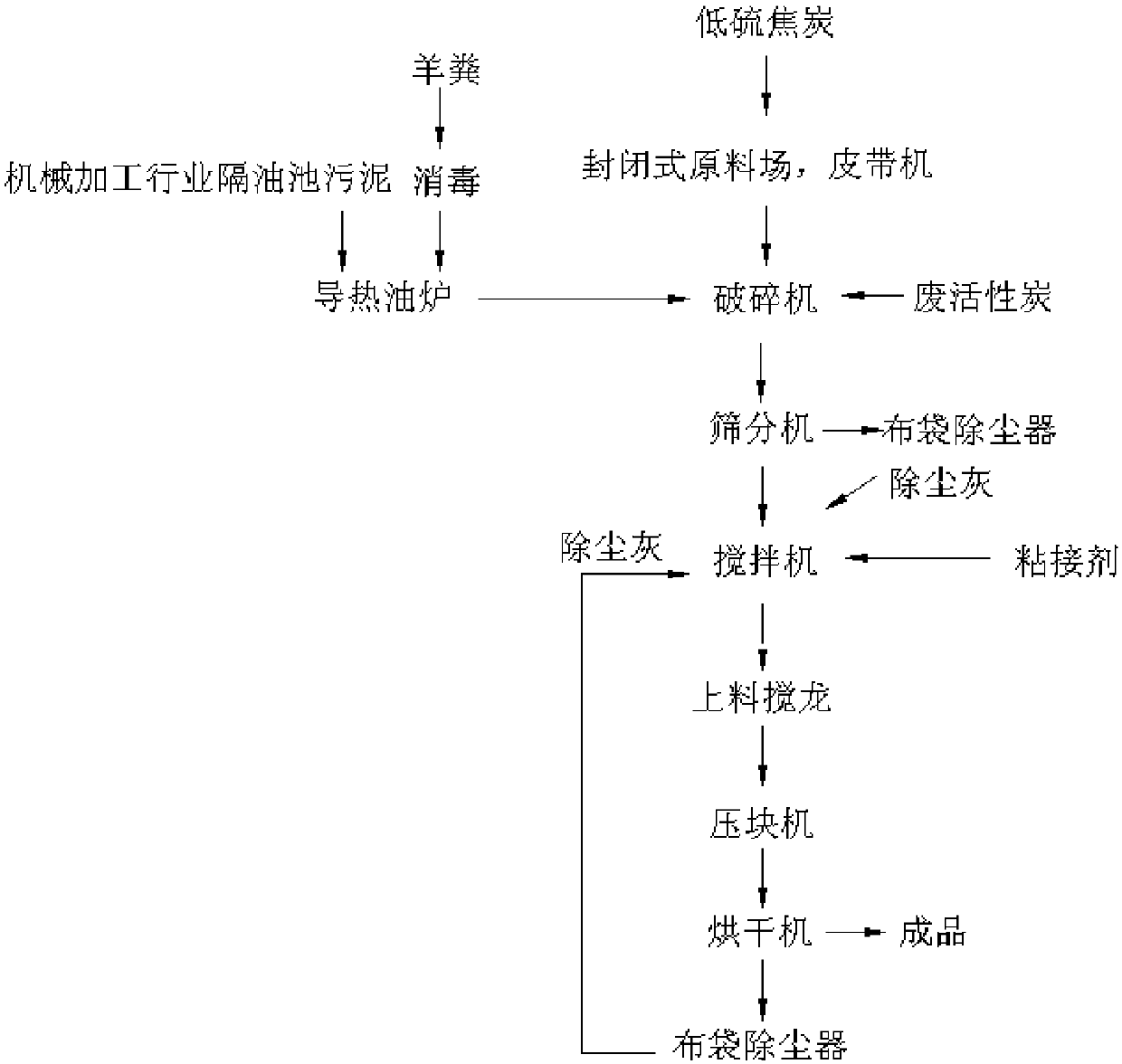

[0031] According to a second aspect of the present invention, the present invention provides a method for preparing the above-mentioned biomass briquettes, comprising the steps of:

[0032] (1) Mix paper mill waste liquid, coal tar and water in a weight ratio of 6.5-8:1.8-2.5:0.8-1.2 (preferably 7:2:1) to obtain a binder;

[0033] (2) Add 40-60 parts by weight of coke, 28-48 parts by weight of livestock and poultry excrement through disinfection, 2-22 parts by weight of waste activated carbon, and 0.5-15 parts by weight of oil sludge in the reactor successively, carry out crushing, then add step ( 1) 0.5-15 parts by weight of the prepared binder is bonded to obtain a semi-finished product;

[0034] (3) Dry the semi-finished product.

[0035] In the above method, the sterilized livestock manure is dried at 70-90°C for 4-6 hours so that its moisture content is 2wt%-3wt% before use; the oil sludge is dried at 70-90°C before use Dry for 10-15 hours so that its moisture content i...

Embodiment 1

[0060] The biomass briquette of this embodiment is made of the following raw materials: 50 parts by weight of coke, 38 parts by weight of sterilized livestock and poultry manure, 12 parts by weight of waste activated carbon, 5 parts by weight of sludge, and 5 parts by weight of binder.

[0061] The preparation method of the biomass briquette of the present embodiment is as follows:

[0062] (1) paper mill waste liquid, coal tar and water are uniformly mixed according to a weight ratio of 7:2:1 to obtain a binder;

[0063] (2) Add 50 parts by weight of coke, 38 parts by weight of livestock and poultry excrement through disinfection, 12 parts by weight of waste activated carbon, and 5 parts by weight of oil sludge in the reactor successively, carry out crushing, then add the binder 5 prepared by step (1) Parts by weight are bonded and formed to obtain a semi-finished product;

[0064] (3) Dry the semi-finished product at 1000°C for 10 hours.

Embodiment 2

[0066] The biomass briquette of this embodiment is made of the following raw materials: 45 parts by weight of coke, 33 parts by weight of sterilized livestock and poultry manure, 10 parts by weight of waste activated carbon, 2 parts by weight of sludge, and 2 parts by weight of binder.

[0067] The preparation method of the biomass briquette of the present embodiment is as follows:

[0068] (1) paper mill waste liquid, coal tar and water are mixed evenly according to the weight ratio of 6.5:1.8:0.8 to obtain the binder;

[0069] (2) Add 45 parts by weight of coke, 33 parts by weight of sterilized livestock and poultry manure, 10 parts by weight of waste activated carbon, and 2 parts by weight of oil sludge in the reactor successively, and then crush them, then add the binder 2 prepared in step (1) Parts by weight are bonded and formed to obtain a semi-finished product;

[0070] (3) Dry the semi-finished product at 1200°C for 7 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com