Gas drilling pipe collecting system capable of realizing universal adjustment of angle

A technology of universal adjustment and gas drilling, which is applied in earthwork drilling, wellbore flushing, wellbore/well parts, etc. It can solve the problems of adjusting the angle and direction of the pipeline at will, high work intensity and operation time, and achieves the reduction of labor intensity , Shorten the installation cycle, the effect of high internal pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

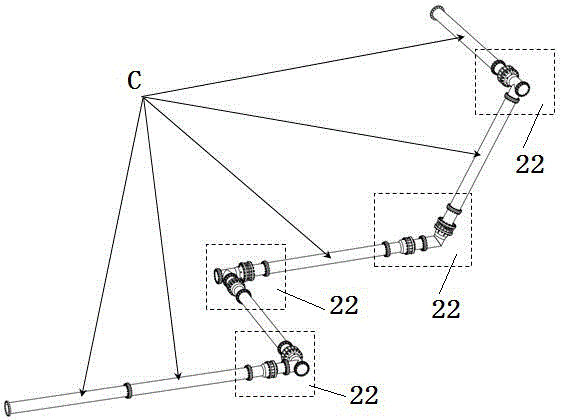

[0041] A gas drilling manifold system capable of universal angle adjustment, including a plurality of adjustment units 22, two adjacent adjustment units are connected by hard pipelines; The angle mechanism is used to adjust any angle within 360° along the radial direction of the manifold.

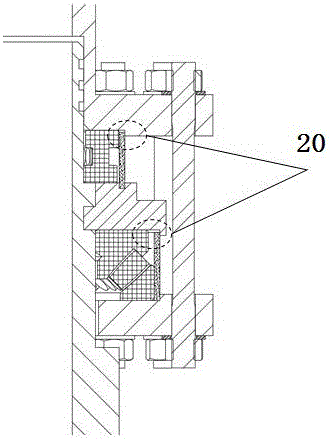

[0042] In this embodiment, the adjustment unit further includes a universal angle fine-adjustment mechanism fixedly connected to the outlet connection end of the rotary nipple 6, and the universal angle fine-adjustment mechanism is used to adjust the axial angle of the manifold.

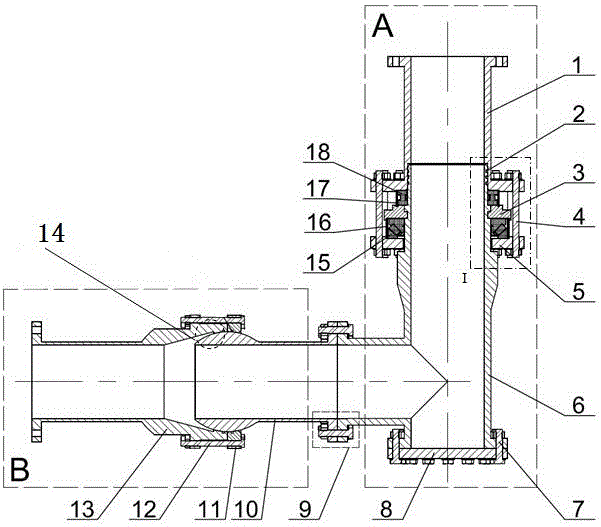

[0043] In this embodiment, the infinitely variable angle mechanism includes a fixed sub-section 1, a clamping piece, a screw set 4, a suspension flange 5 and a rotating sub-joint 6, and the upper end of the rotating sub-joint 6 is inserted and sealed with the fixed sub-section 1 Cooperate, the lower end is provided with a prefabricated fixed-angle outlet connection end, the suspension flange 5 is sleeved on the rota...

Embodiment 2

[0058] This embodiment further illustrates the present invention in conjunction with the accompanying drawings. The invention can be used in gas drilling techniques such as dry gas drilling (air, nitrogen), atomization drilling, foam drilling and aeration drilling, and manifold systems in other fields.

[0059] The invention includes a plurality of adjustment units, and two adjacent adjustment units are connected through a hard pipeline body C. Each adjustment unit includes at least a radial 360° stepless angle change mechanism A, and may also include a universal angle fine-adjustment mechanism B.

[0060] Radial 360° stepless variable angle mechanism A, including fixed nipple 1, "O" type seal ring 2, semicircle card 3, long screw kit 4, suspension flange 5, rotating nipple 6, flange bolt kit 7, Blind plate 8, thrust self-aligning roller bearing 15, dustproof nylon ring a16, dustproof nylon ring b17, thrust cylindrical roller bearing 18. The long screw kit 4 includes a screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com