DNA double-helix micron-scale filter element

A double helix, micron-level technology, applied in the fields of water supply, purification, heating and cooling, can solve the problems of large water flow resistance, poor treatment effect, weak frame, etc., to achieve increased surface area, high exhaust efficiency, and sewage discharge effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. However, it should be understood that these embodiments are only used for more detailed description, and should not be construed as limiting the present invention in any form.

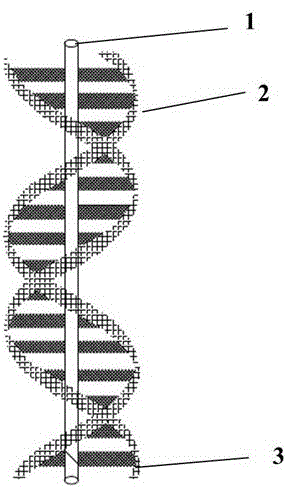

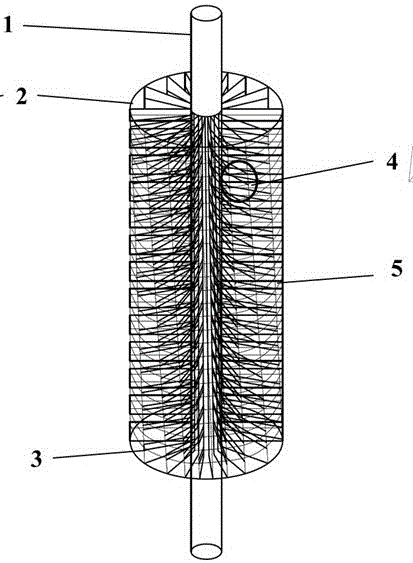

[0031] figure 1 It is a structural schematic diagram of the DNA double-helix micron filter element of the present invention; figure 2 It is a structural diagram of the present invention; image 3 It is a partial structural schematic diagram of the metal filter element of the present invention; Figure 4 It is a cross-sectional view of the DNA double-helix micron filter element of the present invention; Figure 5 It is a section view of the DNA double-helix micron-scale filter element of the present invention.

[0032] See figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , the DNA double-helix micron filter element provided by the present invention can h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com