Automatic sorting device for objects and control method thereof

An automatic sorting and object technology, applied in sorting, conveyor control devices, conveyor objects, etc., can solve problems such as rework, affecting logistics sorting efficiency, offset, etc., and achieve the effect of real-time accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

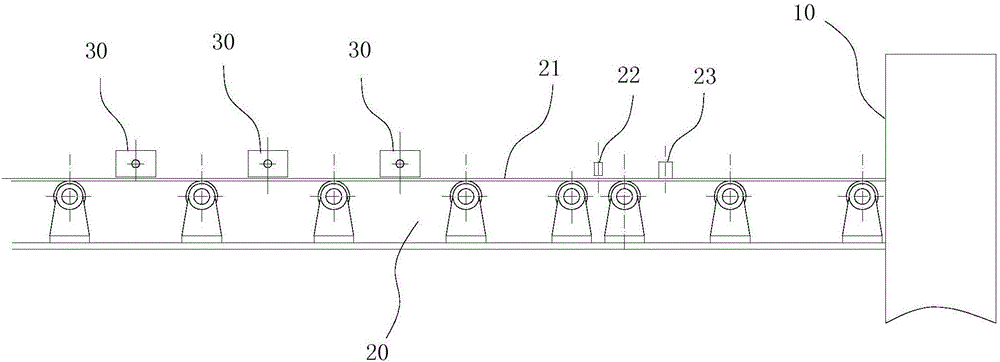

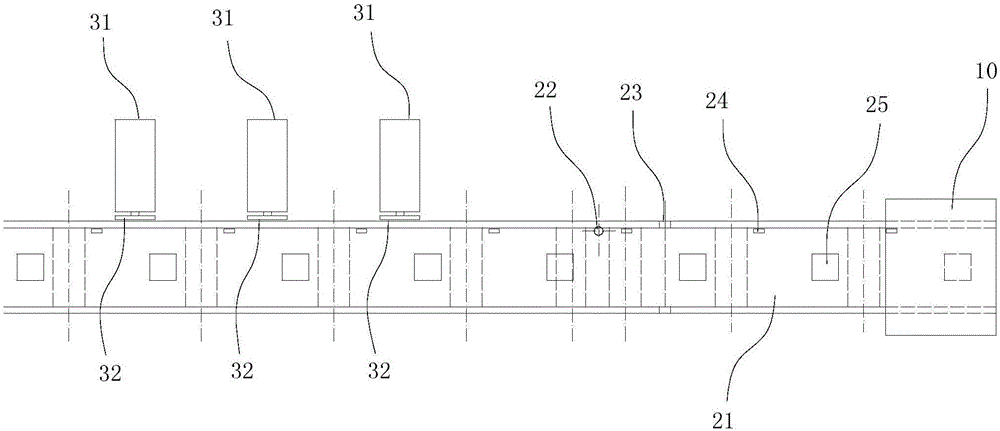

[0061] Such as figure 1 , 2 As shown, an object automatic sorting device includes an object information reading device 10, a belt conveyor 20, a push mechanism 30 and an automatic control module; the object information reading device 10 is used for scanning and identifying information stored on the object medium, the information storage medium can be an image information storage medium such as a barcode, a two-dimensional code, or a radio frequency identification chip storing object information to obtain object delivery information; A plurality of marks or mark points 24 are arranged at intervals, and a mark detection sensor 22 for detecting the marks or mark points 24 is arranged above the belt surface 21; the pushing mechanism 30 reciprocates along the width of the belt surface 21 above the belt surface The direction of motion is set to push objects out from one side of the belt surface 21; the pushing mechanism 30 is arranged at least two groups at intervals along the leng...

Embodiment 2

[0067] A control method of the object automatic sorting device, the system in question has the following basic parameters:

[0068] 1) The maximum delivery interval N of the automatic sorting system 1 = 32;

[0069] 2) The distance between the object information reading device (10) and the object detection sensor (23) is a step distance Z 1 = 1;

[0070] 3) The distance between the mark detection sensor (22) and the object detection sensor (23) is 1.5 steps Z 2 = 1;

[0071] 4) The maximum number of complete steps Z included between the mark detection sensor and the centerline of the first push mechanism 3 = 1;

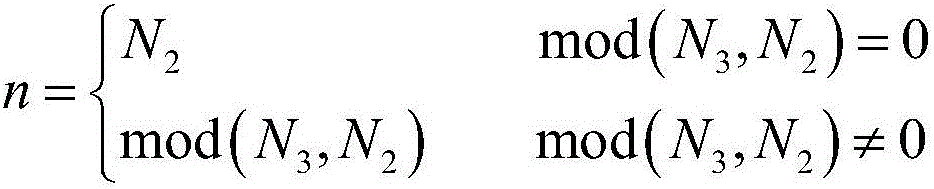

[0072] Calculate the number N of objects that can be marked by the system by formula (1) 2 =32+1+1+1=35, that is, each object has information such as a unique mark or mark point setting value, mark or mark point counter; similarly, the conveyor belt between two marks or mark points also carries Information about whether there is a teleportation object or not. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com