Automatic watt-hour meter lead-sealing bolt aligning system

An automatic alignment and electric energy meter technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as reducing the sealing efficiency of electric energy meters, and achieve the effect of simple structure, convenient wiring installation, and simplified mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

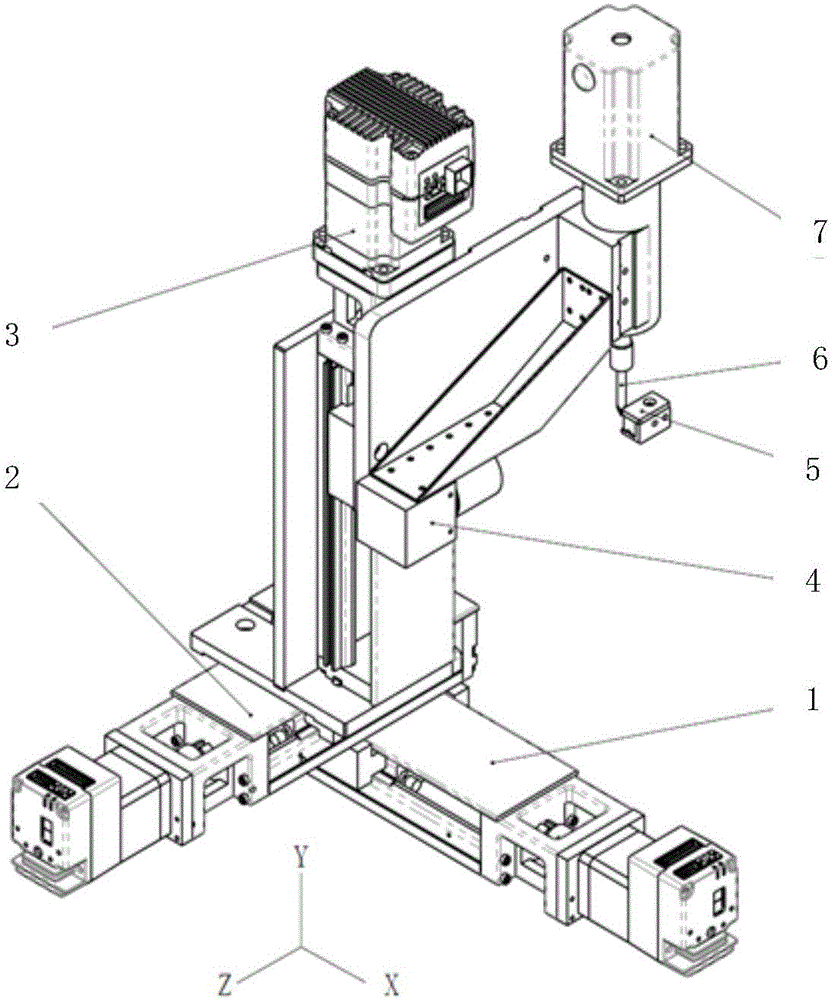

[0023] As shown in the figure, the electric energy meter lead seal screw automatic alignment system provided by this embodiment includes a three-coordinate motion component, an image recognition component, a screw screw machine and a controller;

[0024] The three-coordinate motion assembly includes a motor and an X-axis manipulator 1, a Y-axis manipulator 3, and a Z-axis manipulator 2 respectively connected to the motor;

[0025] The X-axis manipulator performs reciprocating linear motion along the X-axis direction under the drive of the motor; the Y-axis manipulator performs reciprocating linear motion along the Y-axis direction under the drive of the motor; Driven to make reciprocating linear motion along the Z-axis direction;

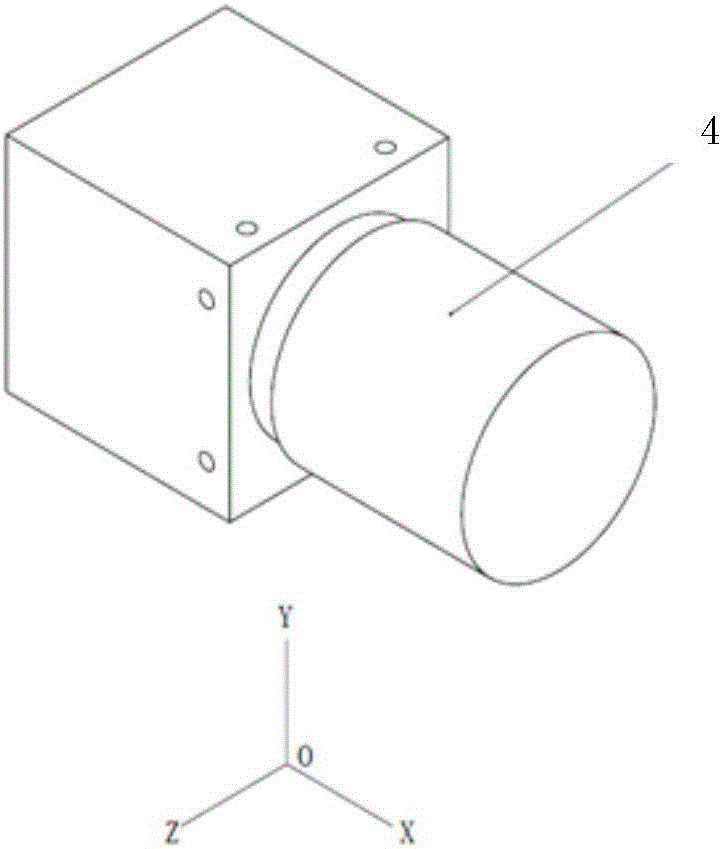

[0026] The image recognition component acquires the position coordinate signal of the object to be detected; the position coordinate signal is input into the controller; the controller generates a control signal for controlling the motor according t...

Embodiment 2

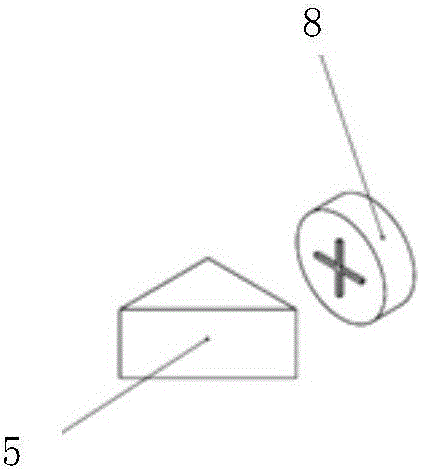

[0032] The electric energy meter lead seal screw automatic alignment system provided in this embodiment uses a camera to perform image recognition and computer control on the object 8 to be tested, so that the equipment is automatically aligned to a certain point in the two-dimensional space; the equipment has a simple structure,

[0033] Including three-coordinate motion components, image recognition components, screwdriver;

[0034] The three-coordinate motion component includes three manipulators, which are X-axis manipulator 1, Y-axis manipulator 3, and Z-axis manipulator 2. Driven by the motor, the X-axis manipulator makes reciprocating linear motion along the X-axis direction; the Y-axis manipulator makes reciprocating linear motion along the Y-axis direction under the drive of the motor; the Z-axis manipulator moves along the Z axis under the drive of the motor Reciprocating linear motion in the axial direction.

[0035] The image recognition component includes a prism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com