Efficient water tank grinding system and method using same

A water tank and high-efficiency technology, which is applied to the parts of grinding machine tools, machine tools suitable for grinding workpiece planes, grinding machines, etc., can solve the problems of inability to meet safe production and flexible production, high incidence of mechanical injuries, and large human injuries from dust. , to achieve the effect of stable processing, reducing mechanical damage and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

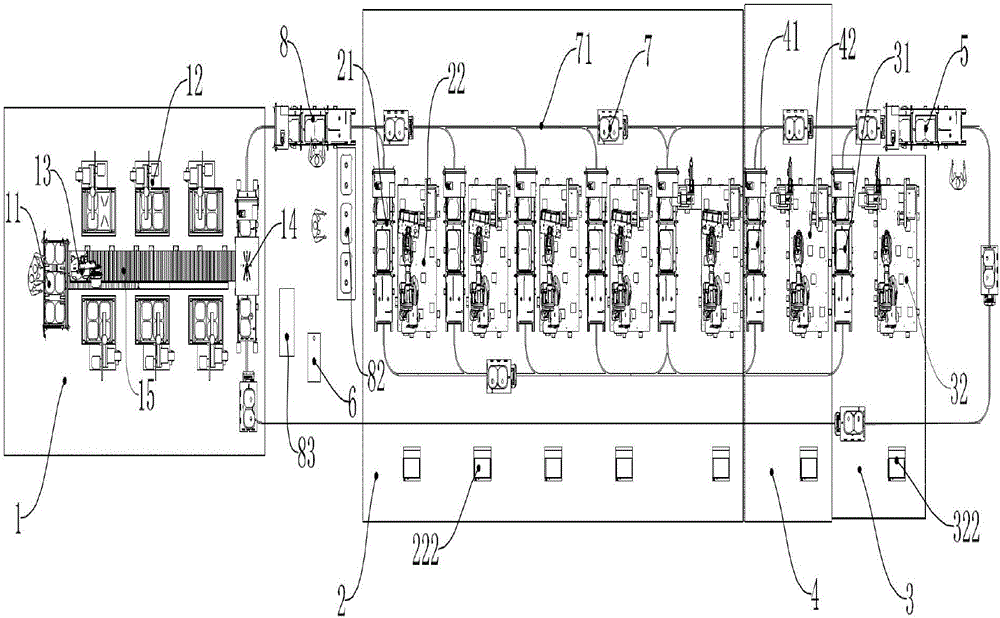

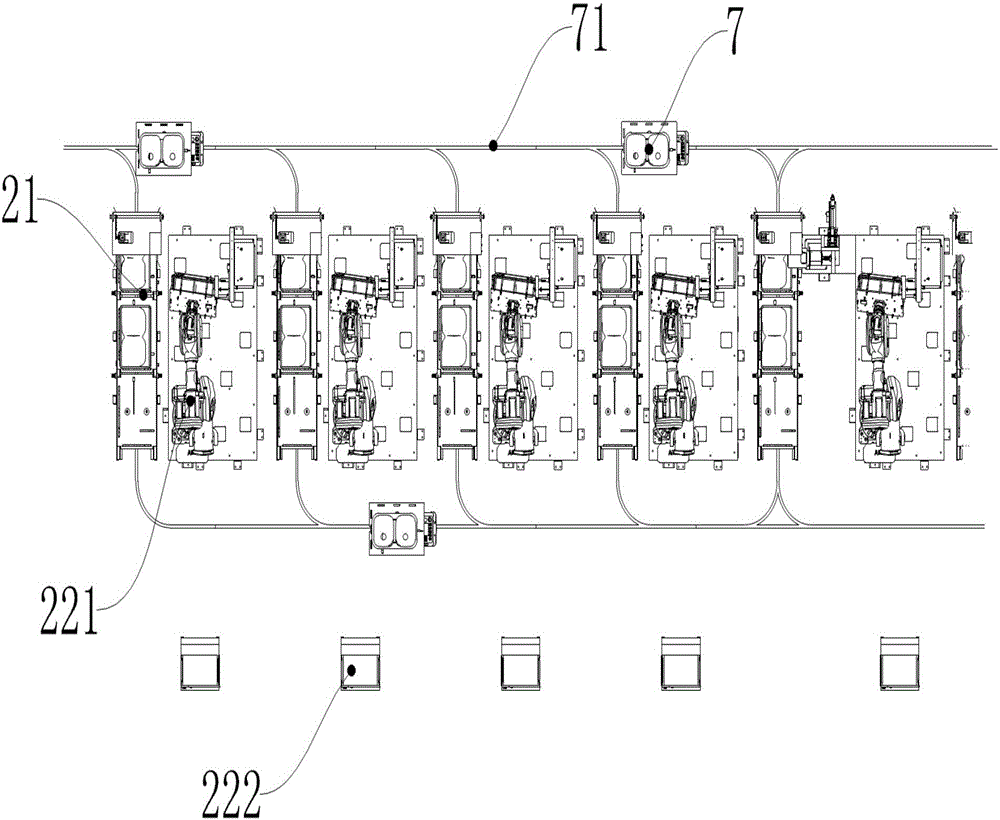

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

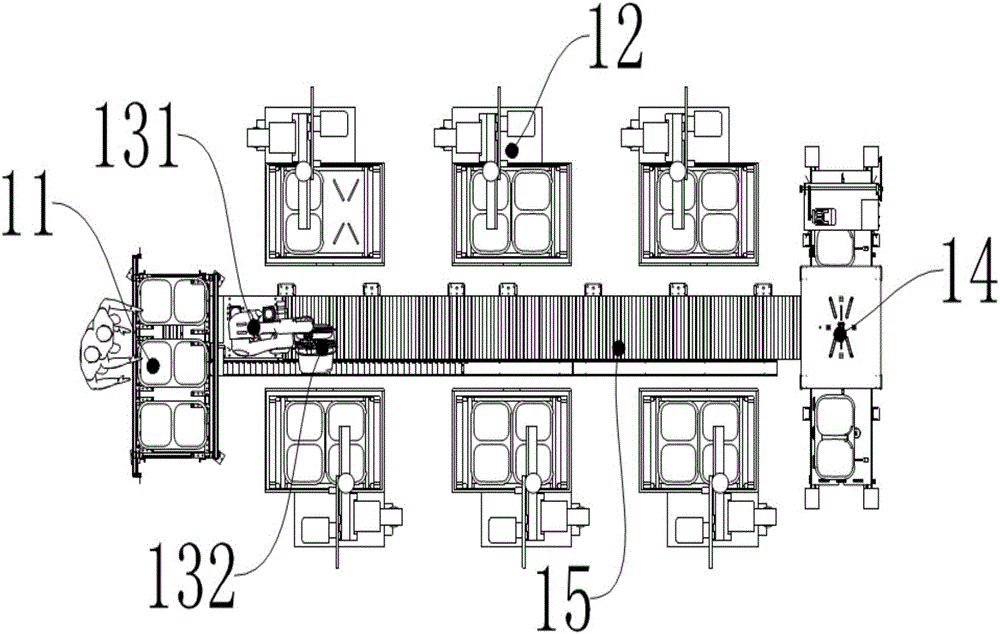

[0033] An efficient sink sanding system such as Figure 1-5 As shown, it includes water tank bottom grinding work area 1, water tank grinding side work area 2, water tank surface grinding work area 3, finished product loading and unloading station 5, handling AGV7 and AGV track 71;

[0034] The sink bottom grinding work area 1 includes a loading platform 11, a semi-finished product loading and unloading station 14, a special grinding machine 12, a robot device 13 and a robot seventh axis 15, and the robot seventh axis 15 is arranged on the loading platform 11 and the semi-finished product loading and unloading station 14; the bottom grinding machine 12 is provided with multiple sets, and is respectively arranged on both sides of the seventh axis 15 of the robot, and the robot device 13 is used to mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com