Hyperbolic nozzle of sand blasting machine

A hyperbolic, sandblasting machine technology, applied in the directions of spray guns, explosion generating devices, abrasives, etc., can solve the problem of low acceleration efficiency, and achieve the effects of simple structure, improved acceleration efficiency and ideal use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

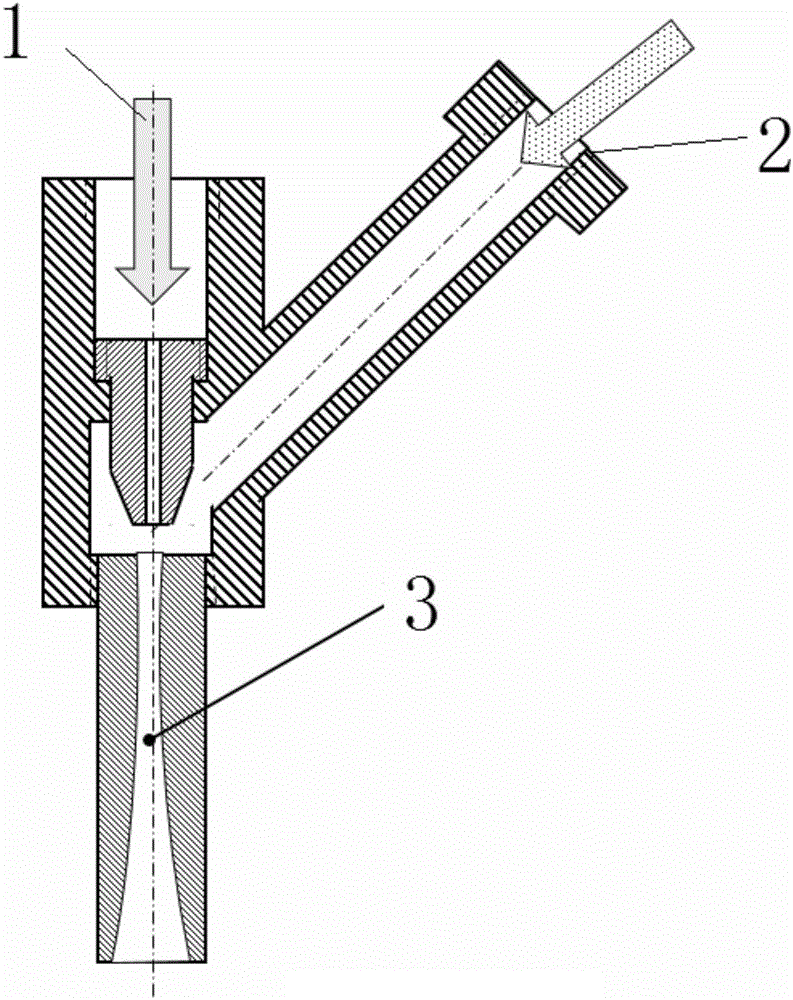

[0009] Embodiment of the present invention: the hyperbolic nozzle of sand blasting machine comprises air inlet 1, sand inlet 2, is provided with hyperbolic nozzle 3 just below the air valve of inlet 1; The section is a hyperbolic structure, and the diameter of the inner cavity top of the hyperbolic spout 3 is 5mm, the diameter of its bottom is 12mm, and the length is 12mm; the curve of its hyperbola is as shown in formula I:

[0010] (X / 2.5) 2 +(Y / 57) 2 = 1 (I).

[0011] Due to the adoption of the structure of the above embodiment, compared with the nozzle of the existing straight pipe nozzle, under the same compressed air power, the effect of sandblasting is improved by 2-3 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tip diameter | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com