Frequency-converting control magnetic suspension screw rod mechanism for injection molding machines

A variable frequency and magnetic levitation technology, applied in the field of injection molding machine equipment, can solve the problems of affecting the auditory system of the operator, damaging the screw or hydraulic cylinder, and easy wear of the screw, so as to improve the efficiency of injection molding processing, reduce the cost of hardware machinery, and prolong the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

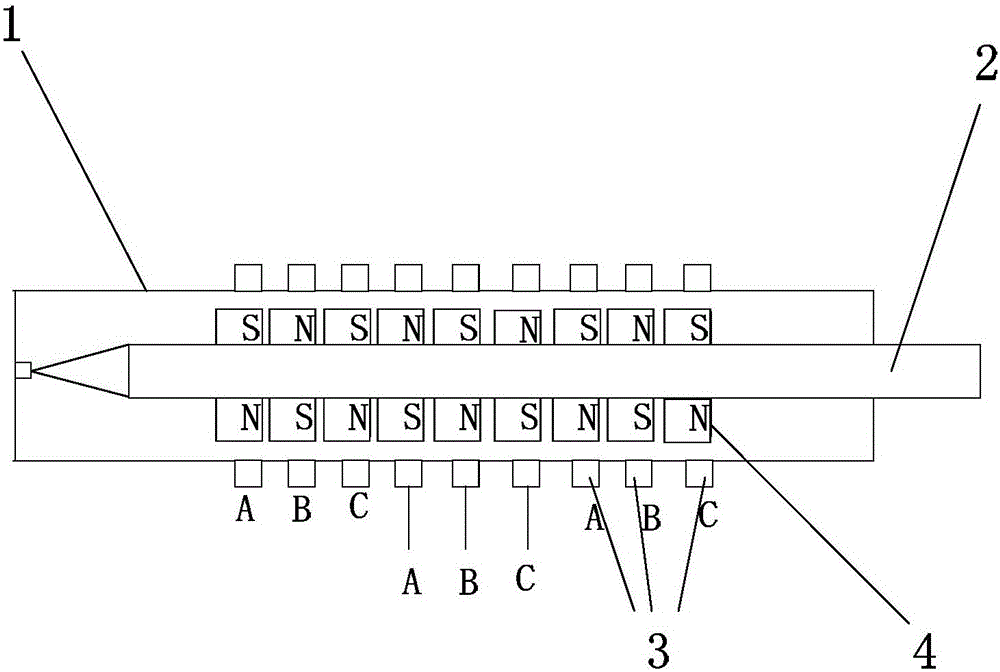

[0019] refer to figure 1 and figure 2 , the present invention is a variable frequency control magnetic levitation screw mechanism for injection molding machines, including a barrel 1 and a screw 2 arranged at the inner axis of the barrel 1, and the screw 2 is provided with multiple sets of magnet groups 4 in the axial direction , the barrel 1 is provided with a plurality of three-phase windings 3 corresponding to each magnet group 4 .

[0020] Further as a preferred embodiment, each of the magnet groups 4 includes a plurality of permanent magnets, the number of the permanent magnets is an even number, and the plurality of permanent magnets are symmetrically installed on the screw rod 2, and the adjacent permanent magnets opposite polarity.

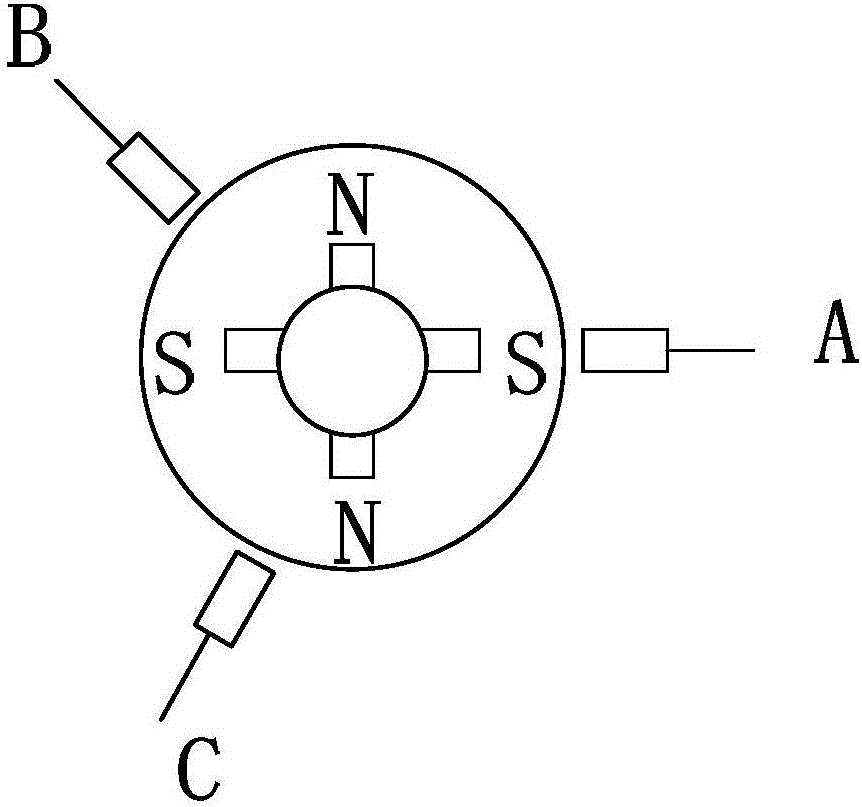

[0021] Further as a preferred embodiment, the three-phase winding 3 includes a-phase winding, b-phase winding and c-phase winding, and the a-phase winding, b-phase winding and c-phase winding are installed on the barrel 1 and along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com