Full-color 3D printing device and method

A 3D printing, full-color technology, applied in the field of 3D printing technology, can solve the problems of difficult color switching, small amount of glue, etc., to achieve the effect of less usage, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

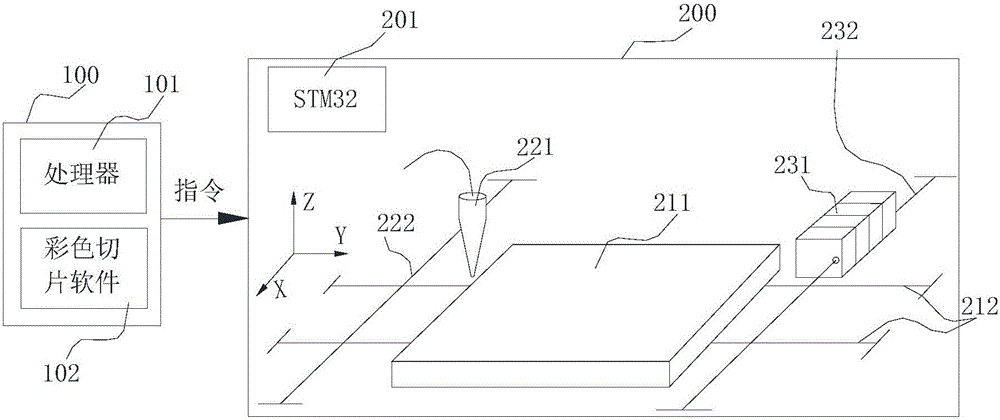

[0051] Such as figure 1 As shown, a color 3D printing device mainly includes: a computer system 100, a processor 101, a color slicing module 102, a control board (not shown), a working platform 211, a working platform transmission mechanism 212, a wire extrusion head 221, a wire Extrusion head transmission mechanism 222, color inkjet head 231, inkjet head transmission mechanism 232, color ink cartridge (not shown).

[0052] A processor (i.e. CPU) 101, a memory (not shown), a USB interface (not shown), a keyboard and a mouse (not shown) are included in the computer system 100, and a color slice module 102 is installed in the computer system, The processor 101 completes the slicing of the color model by executing functions or instructions in the color slicing module 102 .

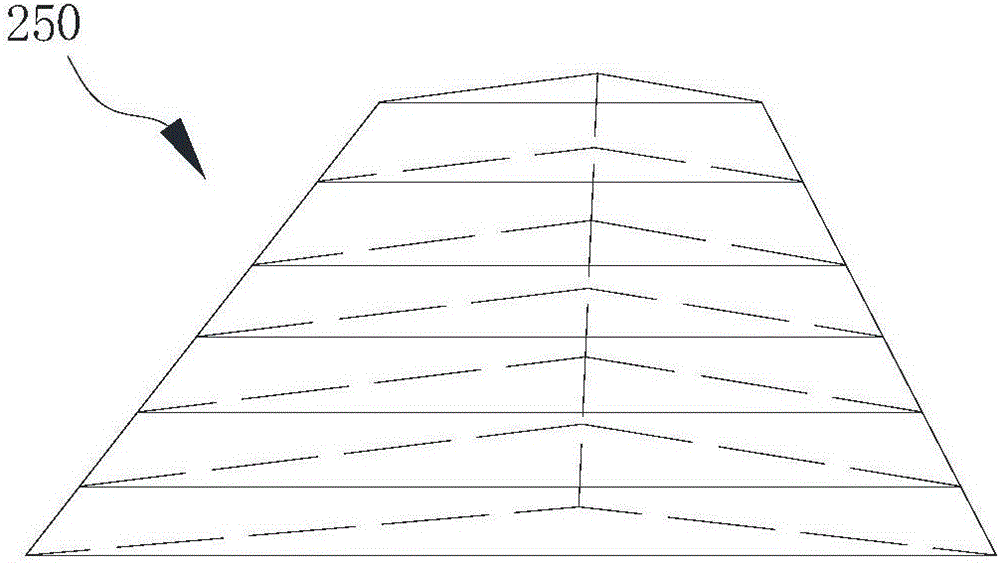

[0053] Input the color model into the color slicing module 102, and the software can process the model in layers according to the layer thickness and the three-dimensional size of the model, obtain the cross...

Embodiment 2

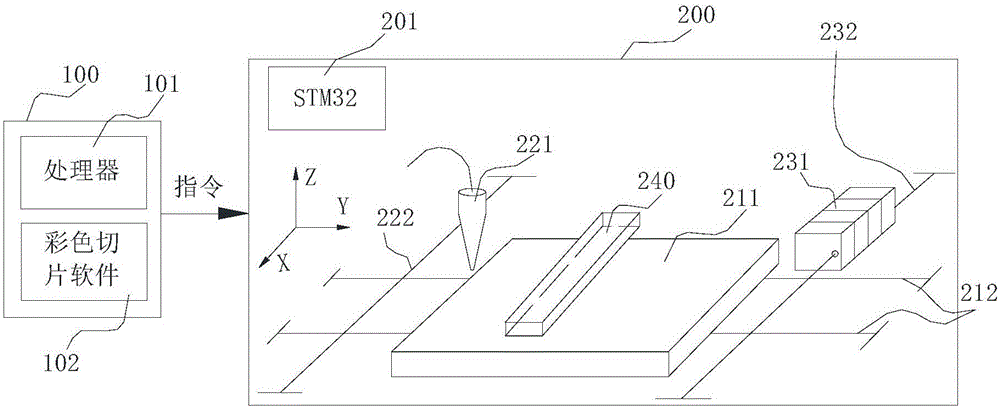

[0058] Such as figure 2 As shown, on the basis of Embodiment 1, a color ink curing device 240 is further installed. The curing device 240 uses an infrared light source to cure the ink after the surface of each layer of material is colored to enhance the coloring effect.

Embodiment 3

[0060] On the basis of Embodiment 1, a state feedback mechanism is added, such as Figure 6 shown. The control board switches between physical printing and coloring according to the state information, and completes alternate 3D printing and inkjet coloring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slice thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com