3D printing production device and weaving method improved by combining textile manufacturing principle

A technology of 3D printing and production equipment, which is applied in textiles and papermaking, textile, additive manufacturing, etc. It can solve the problems of reducing production process, shortening production cycle, insufficient strength, etc., and achieves the goal of improving the mechanical properties of products and satisfying the concept of convenient design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

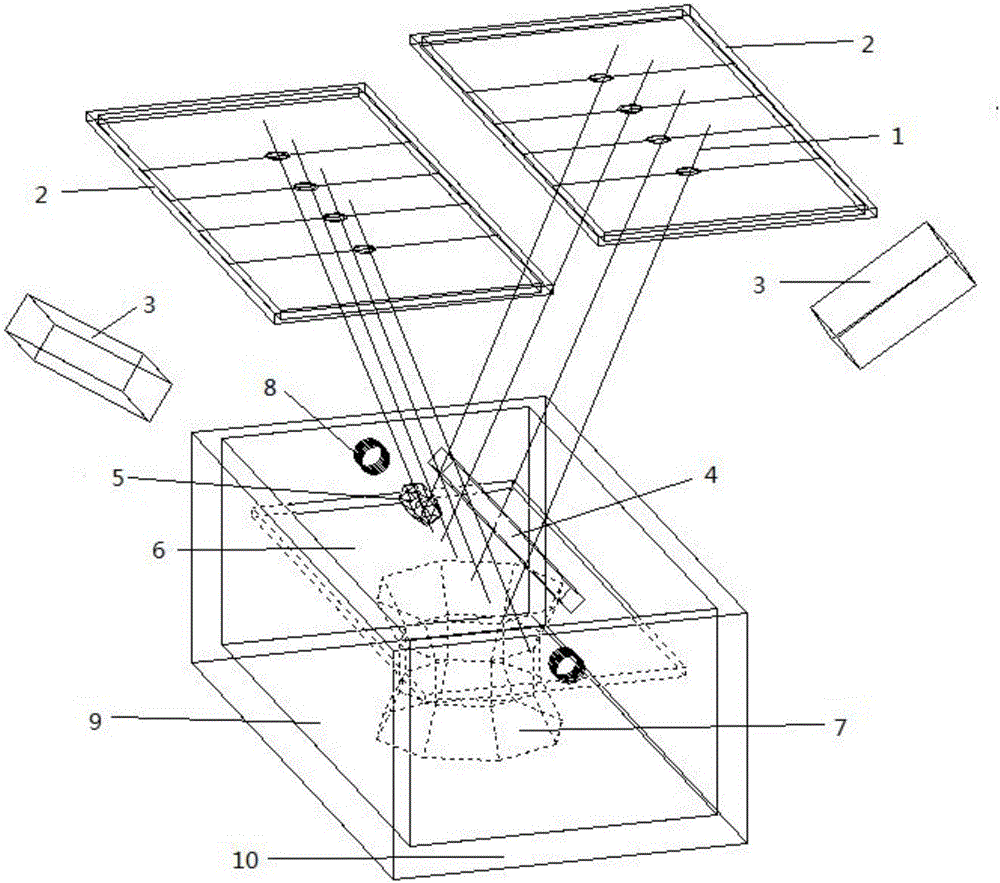

[0014] An improved 3D printing production device combined with textile manufacturing principles in this embodiment such as figure 1 As shown, including a frame, the frame (not shown) is sequentially installed with 2 heald frames 2, 1 beating bar 4, and 1 shuttle 5 from top to bottom. A 3D printer 9 is also installed below the heald frame 2, and the shuttle 5 is located above the inside of the 3D printer 9; the side walls on both sides of the 3D printer 9 are provided with pick-up holes 8, and The described pick-up hole 8 is located at the same height as the shuttle 5; the liquid storage tank 10 is installed in the described 3D printer 9; the inner bottom surface of the liquid storage tank 10 below the shuttle 5 is equipped with The lifting device 7 formed; the lifting platform 6 is installed on the lifting device 7, and the lifting platform 6 is located below the shuttle 5; 2 lasers are symmetrically installed on the frame above the 3D printer 9 Transmitter 3, and the instal...

Embodiment 2

[0019] An improved 3D printing production device combined with textile manufacturing principles in this embodiment such as figure 1 As shown, including a frame, the frame (not shown) is sequentially installed with 2 heald frames 2, 1 beating bar 4, and 1 shuttle 5 from top to bottom. A 3D printer 9 is also installed below the heald frame 2, and the shuttle 5 is located above the inside of the 3D printer 9; the side walls on both sides of the 3D printer 9 are provided with pick-up holes 8, and The described pick-up hole 8 is located at the same height as the shuttle 5; the liquid storage tank 10 is installed in the described 3D printer 9; the inner bottom surface of the liquid storage tank 10 below the shuttle 5 is equipped with The lifting device 7 formed; the lifting platform 6 is installed on the lifting device 7, and the lifting platform 6 is located below the shuttle 5; 2 lasers are symmetrically installed on the frame above the 3D printer 9 Transmitter 3, and the instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com