Double barrel material compound machine compound transmission mechanism

A compound transmission and transmission mechanism technology, applied in lamination, lamination devices, chemical instruments and methods, etc., can solve the problems of affecting the wearing effect, fabric and lining movement, and unsightly appearance, so as to avoid slipping and enhance The effect of high friction and flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

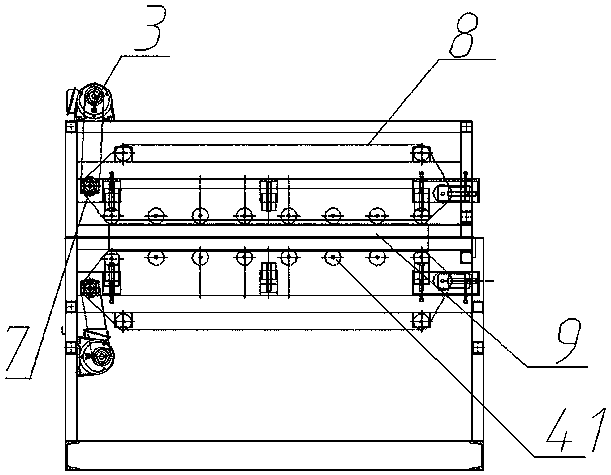

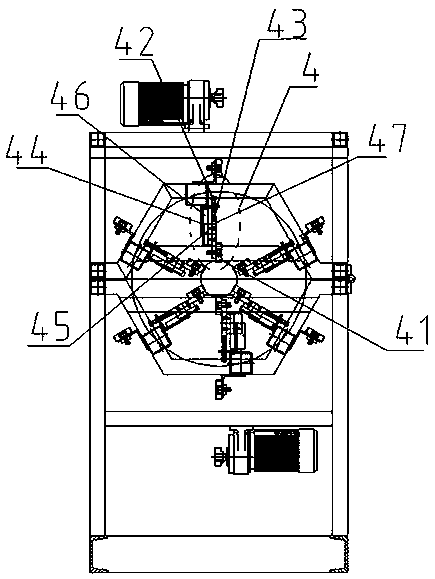

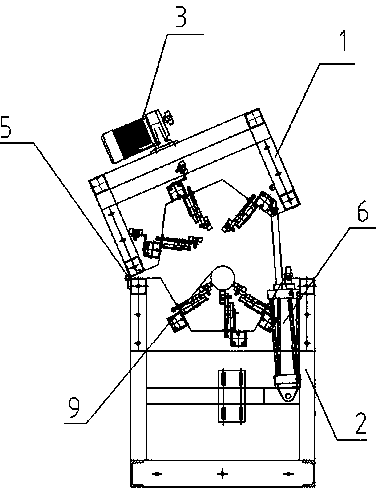

[0017] Such as figure 1 The compound transmission mechanism of a double-barreled material composite machine includes a frame, and multiple sets of ring-shaped transmission mechanisms are arranged on the frame from left to right, and the ring-shaped transmission mechanism is provided with at least 6 groups. The annular transmission mechanism includes at least 6 groups of synchronous wheel transmission systems 4, and each group of synchronous wheel transmission systems 4 is arranged in a ring around the center of the frame. The synchronous wheel transmission system 4 of each group forms a circular structure, which is matched with the circular structure formed by multiple sets of annular transmission mechanisms to form a cylindrical space for placing the fabric sleeve 9 .

[0018] Described synchronous wheel transmission system 4 comprises synchronous wheel 41, synchronous wheel installation frame 47, fixed screw rod 42, spring 43 and fixed guide plate 44, wherein synchronous wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com