Method of packaging spacer and packaging spacer

A spacer and article technology, applied in the field of packaging, can solve problems such as poor heat dissipation, reduced protection, and punctured inflatable bags, and achieve the effects of small footprint, convenient operation, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

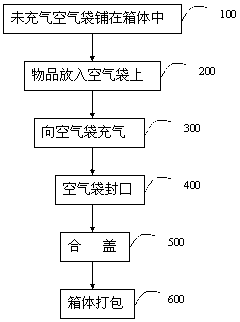

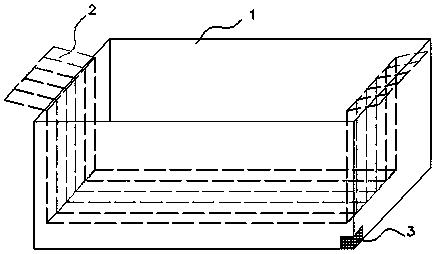

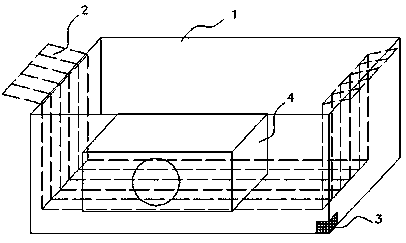

[0020] figure 1 Shown is a method for packaging spacers according to the present invention, including an air bag 2 and a reinforcing member 3. The air bag 2 is placed in a packing box 1. The use of the air bag 2 includes the following steps: Step 100, the uninflated The air bag 2 is placed in the bag box 1, see figure 2 ; Step 200, put the stereo 4 into the air bag 2, see image 3 ; Step 300, inflate the air bag 2, see Figure 4 ; Step 400, heat-sealing the mouth of the air bag; Step 500, closing the lid; Step 600, packing the box.

[0021] Further, in this embodiment, on the basis of the above embodiments, the reinforcing member 3 is a three-dimensional XYZ axial cardboard corner piece, which is placed at the four bottom corners of the box body 1 .

[0022] As an alternative embodiment, the reinforcing member 3 is a long L-shaped cardboard corner piece placed on the four bottom edges of the box body 1 .

[0023] It can be seen that the audio package is safe and convenien...

Embodiment 2

[0025] Figure 5 It is another schematic diagram of the air bag of the present invention laid in the box. The two inflatable bags 2 that are not inflated are respectively closely attached to the opposite sides of the box body 1 in pairs, and the bottoms are laminated and tiled. The air bag 2 is all filled with air, and then the audio system 4 is protected by the air bag all around.

[0026] As an alternative embodiment, the reinforcement 3 is a three-dimensional XYZ axial cardboard corner piece, which is placed at the four bottom edges of the box and the inner corners of the air bag.

[0027] Further, as an alternative embodiment, the reinforcing member 3 is a long L-shaped cardboard corner piece, which is placed on the four bottom edges of the box body 1 and the inner edge of the air bag at the same time.

[0028] It can be seen that the audio packaging is safe and convenient, and the corners of the audio will not damage the inflatable bag.

Embodiment 3

[0030] As a changeable embodiment, the reinforcing member 3 is cardboard, and is laid flat on the upper surface and the lower surface of the inflatable bag at the same time.

[0031] As a changeable embodiment, the reinforcing member 3 is cardboard, and is laid flat on the front surface and the rear surface of the side of the inflatable bag near the box.

[0032] It can be seen that the audio packaging is safe and convenient, and the impact of the audio on the inflatable bag is greatly alleviated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com