Light transmittance zirconium oxide sintered body, preparation method and application thereof

A technology of zirconia and sintered body, applied in zirconia, dental preparations, dental prosthesis, etc., can solve the problems of unsightly appearance, low permeability of zirconia, poor overall texture and jade feeling, and achieve strong denture texture and jade Good texture and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

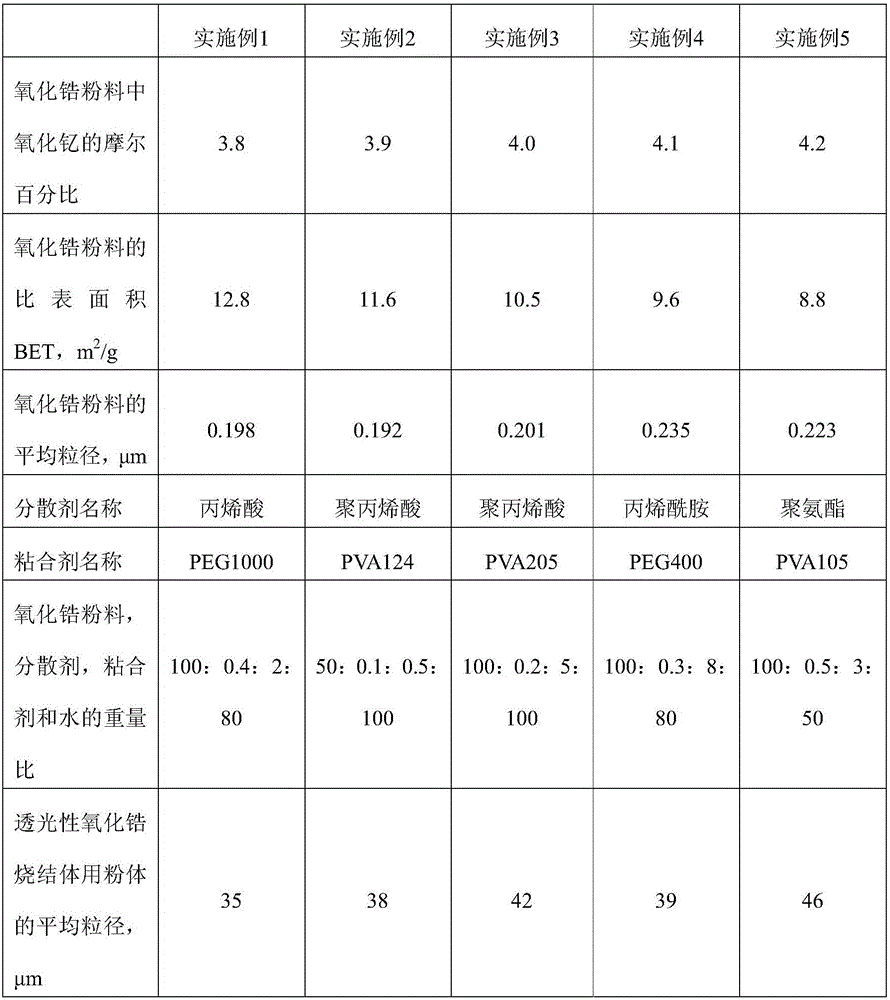

[0025] Example 1-5 Powder for translucent zirconia sintered body

[0026] The powder for the translucent zirconia sintered body of the present invention can be prepared according to the following method: dispersing the zirconia powder in pure water, adding an appropriate amount of dispersant and binder, mixing to form a slurry, and then spraying The powder is obtained in the form of granules, which is used to prepare a light-transmitting zirconia sintered body. (Table 1)

[0027] Table 1 Powder for light-transmitting zirconia sintered body

[0028]

[0029] The zirconia powder is prepared by hydrothermal synthesis, comprising the following steps:

[0030] S1. Mix soluble zirconium salt (zirconium nitrate) and yttrium salt (yttrium nitrate) in proportion and dissolve in water, slowly add ammonia water under stirring condition, and use ammonia water to adjust the pH of the slurry to 8-10;

[0031] S2. Transfer the above slurry to a reaction kettle, and perform hydrothermal...

Embodiment 6-10

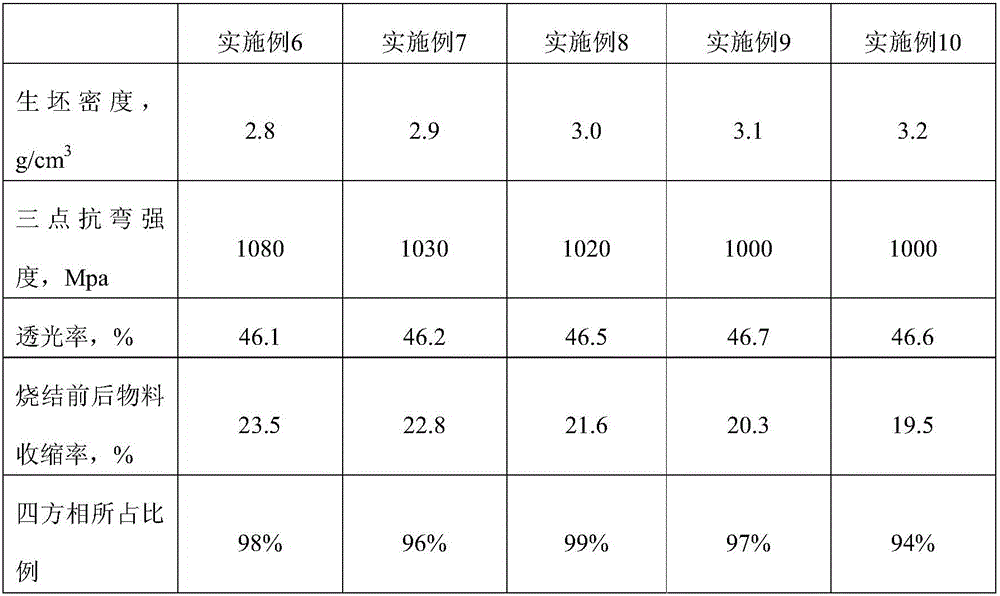

[0035] Example 6-10 Translucent zirconia sintered body and preparation method thereof

[0036] The powder prepared in Examples 1-5 is molded into a green body by isostatic pressing (150-200MPa holding pressure for 10-50s), and the green body is degreased and biscuited at 900-1100° C. Carry out high-temperature sintering at 1400-1550° C. for 1-4 hours to obtain a light-transmitting zirconia sintered body.

[0037] The indicators of the obtained sintered body products are shown in Table 2.

[0038] Table 2 Indicators of Translucent Zirconia Sintered Products

[0039]

[0040] The translucent zirconia sintered body provided by the invention can be used in dental powders such as dental fixed restorations, such as dentures.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com