A new type of magnesia-alumina-carbon brick made of carbon-containing residual ladle lining brick and its production method and application

A technology of ladle lining bricks and magnesia-aluminum-carbon bricks is applied to the application of magnesia-aluminum-carbon bricks on ladle, and the production field of magnesia-alumina-carbon bricks can solve the problem that the service life cannot reach the expected replacement period, and the steelmaking process requirements cannot be met. , waste of refractory materials, etc., to achieve the effect of improving corporate and social benefits, saving refractory resources and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In this embodiment, a new type of magnesia-alumina-carbon brick made of carbon-containing residual ladle lining brick according to the present invention has the following formula by weight: carbon-containing residual ladle lining brick: 40 parts; magnesia: 40 parts ; Alumina: 10 parts; Carbon: 5 parts; Metal magnesium powder: 5 parts; %, fine powder below 180 mesh 20%.

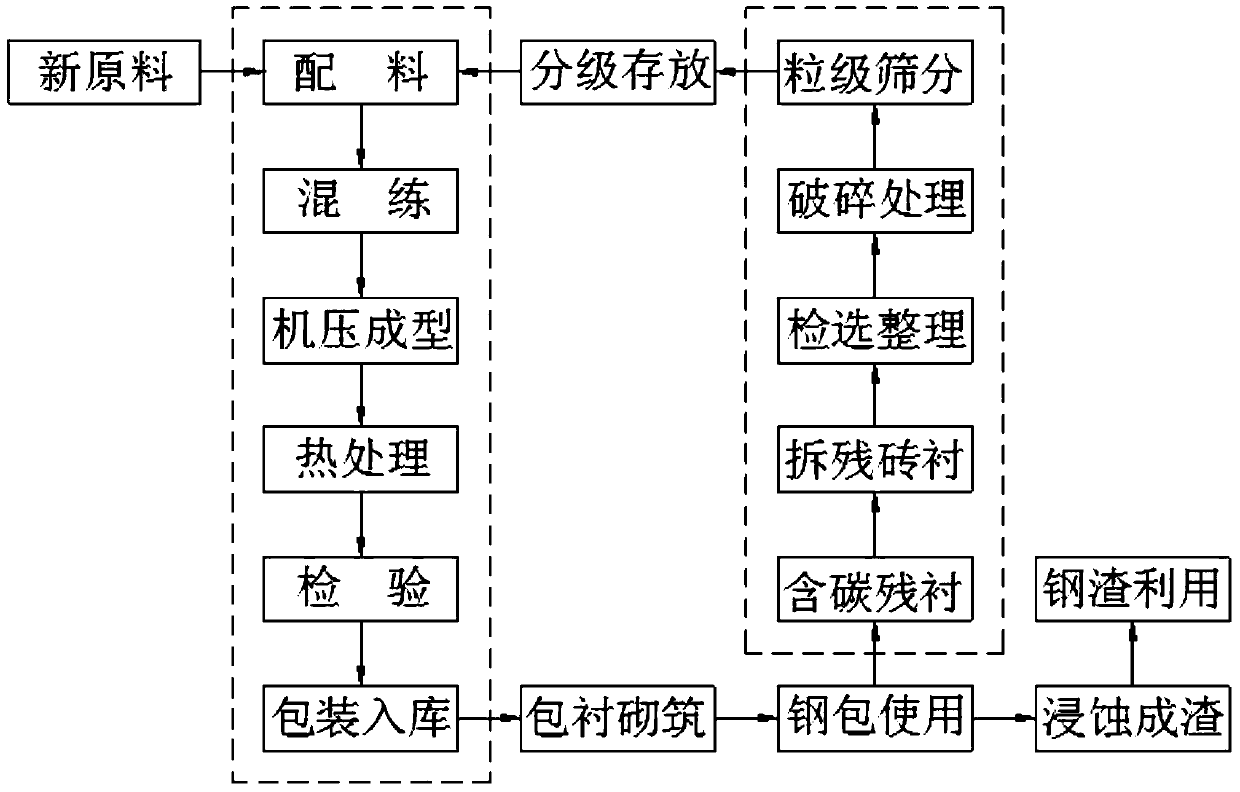

[0043] like figure 1 A flow chart of a production method of a novel magnesia-alumina-carbon brick made of carbon-containing residual ladle lining brick is shown, and the method includes the following specific steps:

[0044] Step S1, collection and processing of residual carbon-containing ladle lining bricks

[0045] 1) Stack the removed carbon-containing residual ladle lining bricks in a centralized manner, manually check and select the carbon-containing residual ladle lining bricks with special equipment, and then remove the steel slag on the working layer of the carbon-containing residual ladle lin...

Embodiment 2

[0063] In this embodiment, a new type of magnesia-alumina-carbon brick made of carbon-containing residual ladle lining brick according to the present invention has the following formula by weight: carbon-containing residual ladle lining brick: 50 parts; magnesia: 35 parts ; Alumina: 10 parts; Carbon: 2 parts; Borax: 3 parts; Mesh fine powder 20%.

[0064] A kind of production method of the novel magnesia-alumina-carbon brick that utilizes carbon-containing residual ladle lining brick to make of this embodiment, its basic steps are the same as embodiment 1, and its difference is:

[0065] Step S2, raw material preparation

[0066] 1) Prepare according to the ratio of the following raw materials: residual carbon-containing ladle lining brick: 50 parts; magnesia: 35 parts; alumina: 10 parts; carbon: 2 parts; borax: 3 parts; thermosetting resin: 4 parts ;

[0067] 2) The particle size composition of raw materials: 55% of 8mm-1mm coarse particles, 25% of 1-0mm medium particles, ...

Embodiment 3

[0071] In this embodiment, a new type of magnesia-alumina-carbon brick made of carbon-containing residual ladle lining brick according to the present invention has the following formula by weight: carbon-containing residual ladle lining brick: 60 parts; magnesia: 20 parts ; Alumina: 6 parts; Carbon: 6 parts; Boron carbide powder: 8 parts; , 25% of fine powder below 180 mesh.

[0072] A kind of production method of the novel magnesia-alumina-carbon brick that utilizes carbon-containing residual ladle lining brick to make of this embodiment, its basic steps are the same as embodiment 1, and its difference is:

[0073] Step S2, raw material preparation

[0074] 1) Prepare according to the ratio of the following raw materials: carbon-containing residual ladle lining brick: 60 parts; magnesia: 20 parts; alumina: 6 parts; carbon: 6 parts; boron carbide powder: 8 parts; silicone resin: 5 copies;

[0075] 2) Composition of raw material particle size: 60% of 8mm-1mm coarse particles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com