Gas spray cooling system arranged in front of gas holder

A gas tank and gas temperature technology, which is applied to blast furnace parts, furnaces, blast furnace details, etc., can solve the problems of power loss, water resource waste, failure to give full play to the mixing function and heat dissipation capacity of the gas tank, and achieve energy saving and consumption reduction. Service life, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

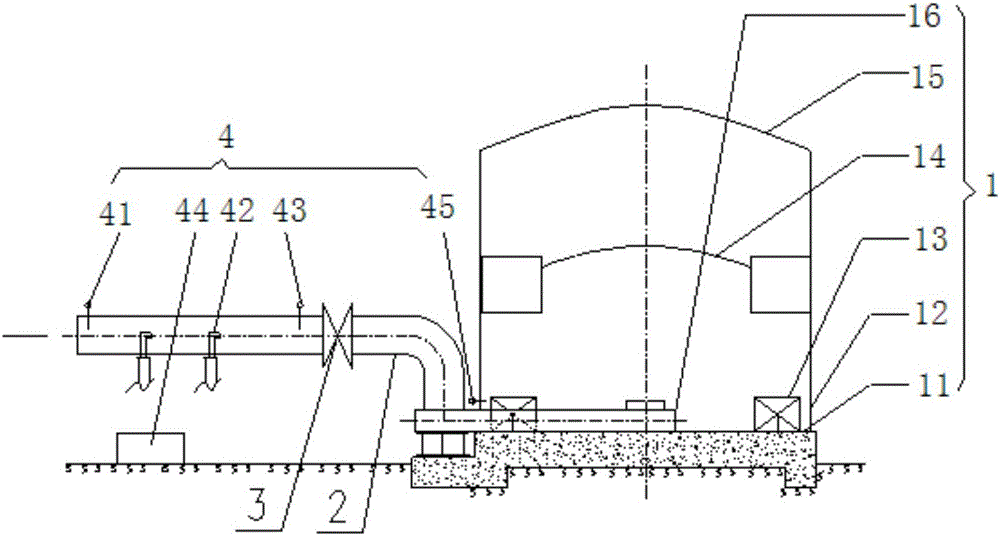

[0016] Such as figure 1 As shown, the gas cabinet 1 is mainly composed of part 11 bottom plate, part 12 piston support, part 13 piston, part 14 barrel, part 15 top cover and part 16 internal gas pipes in the cabinet; the gas spray cooling device is mainly composed of part 41 to flow Gas thermometer, part 42 spray gun, part 43 outflow gas thermometer and part 44PLC frequency conversion control cabinet etc.; Valve 3 is arranged on it, and the gas cabinet 1 is connected with the gas pipeline 2 outside the cabinet by the gas pipeline 16 in the cabinet formed by the cylinder body 14, the piston 12 and the bottom plate 11. The gas pipeline 16 in the cabinet is a gas import an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com