Heat radiator with heat exchange function

A technology of heat dissipation device and cold and heat exchange, which is applied in cooling/ventilation/heating transformation, instruments, electrical digital data processing, etc. the effect of exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

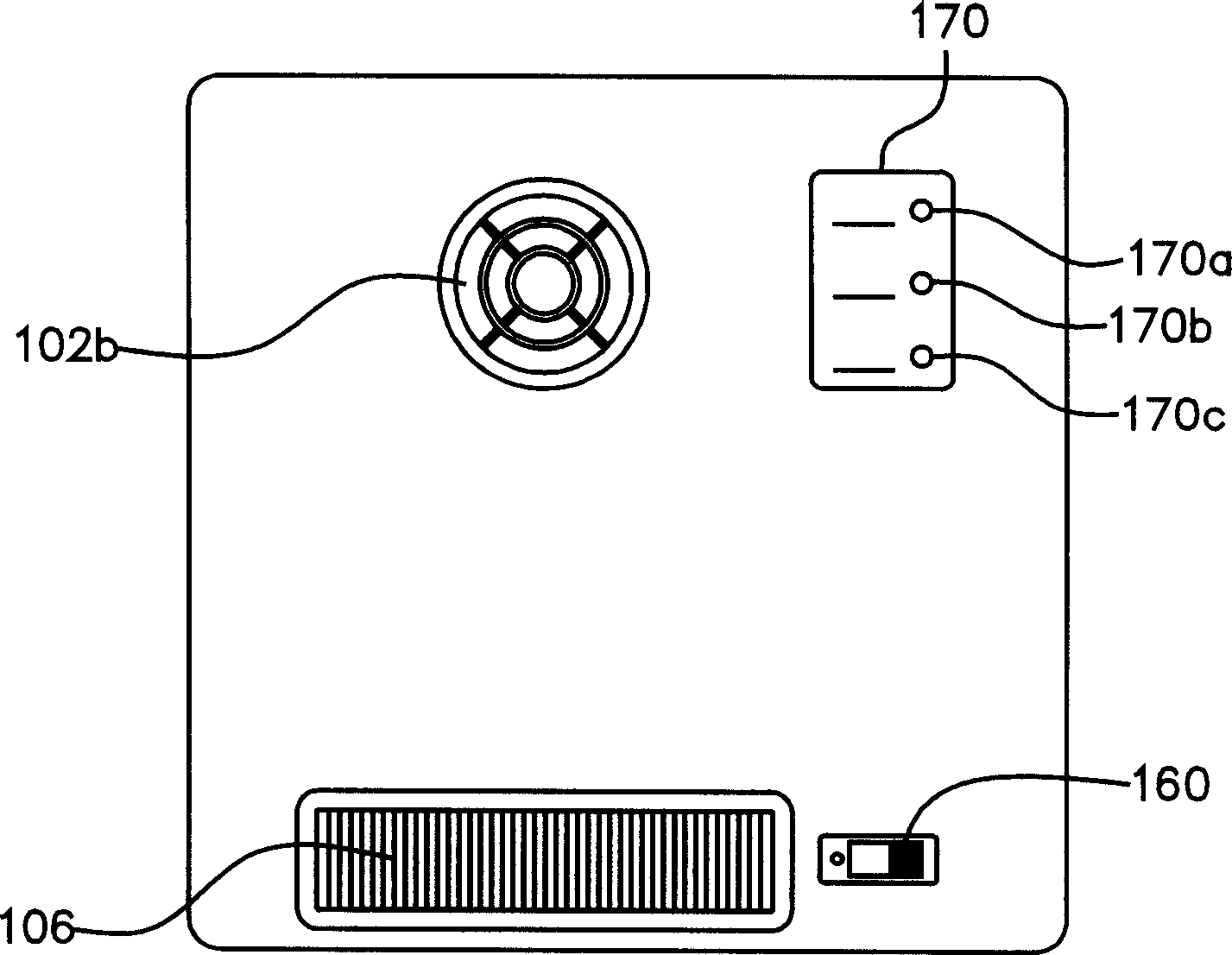

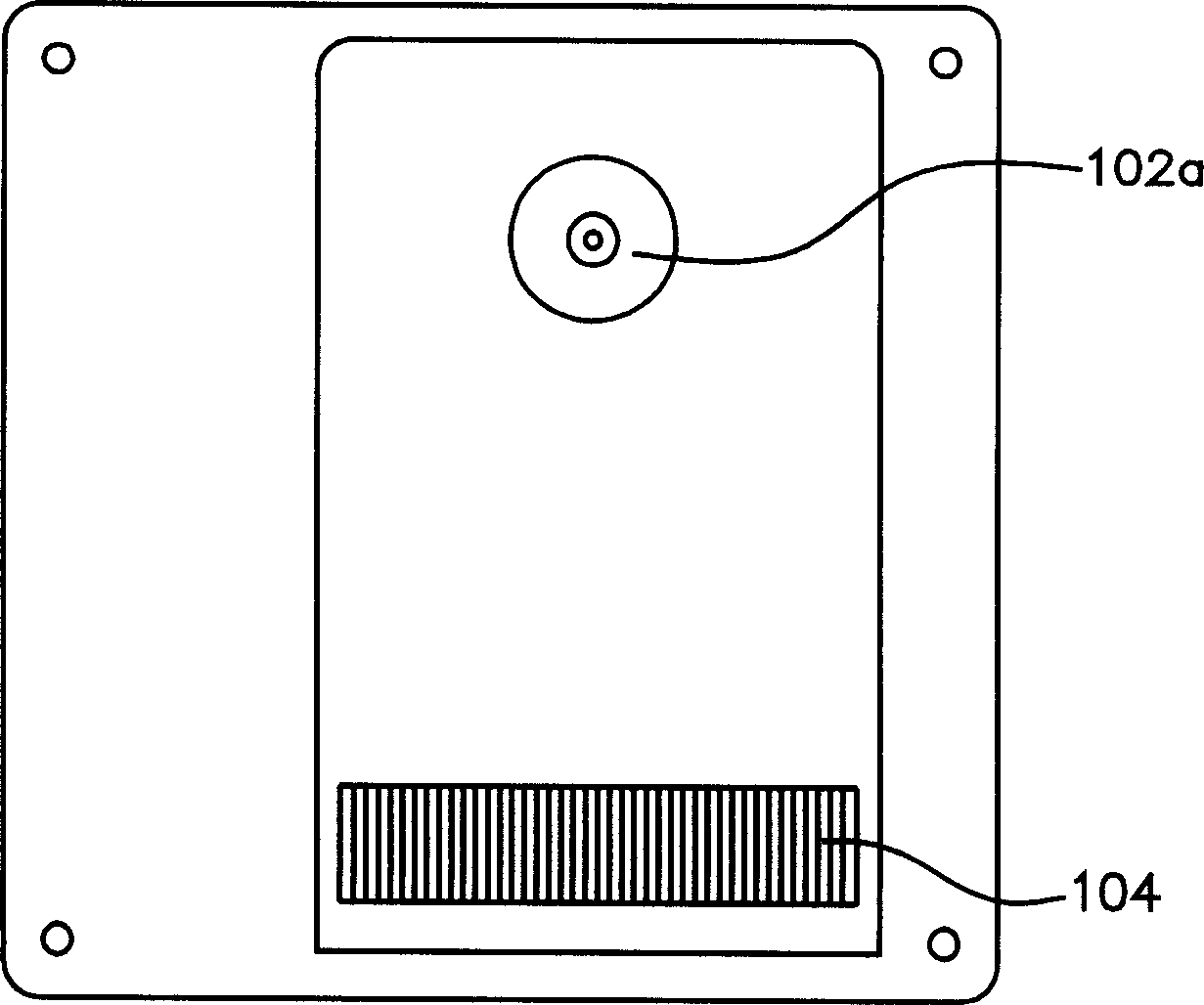

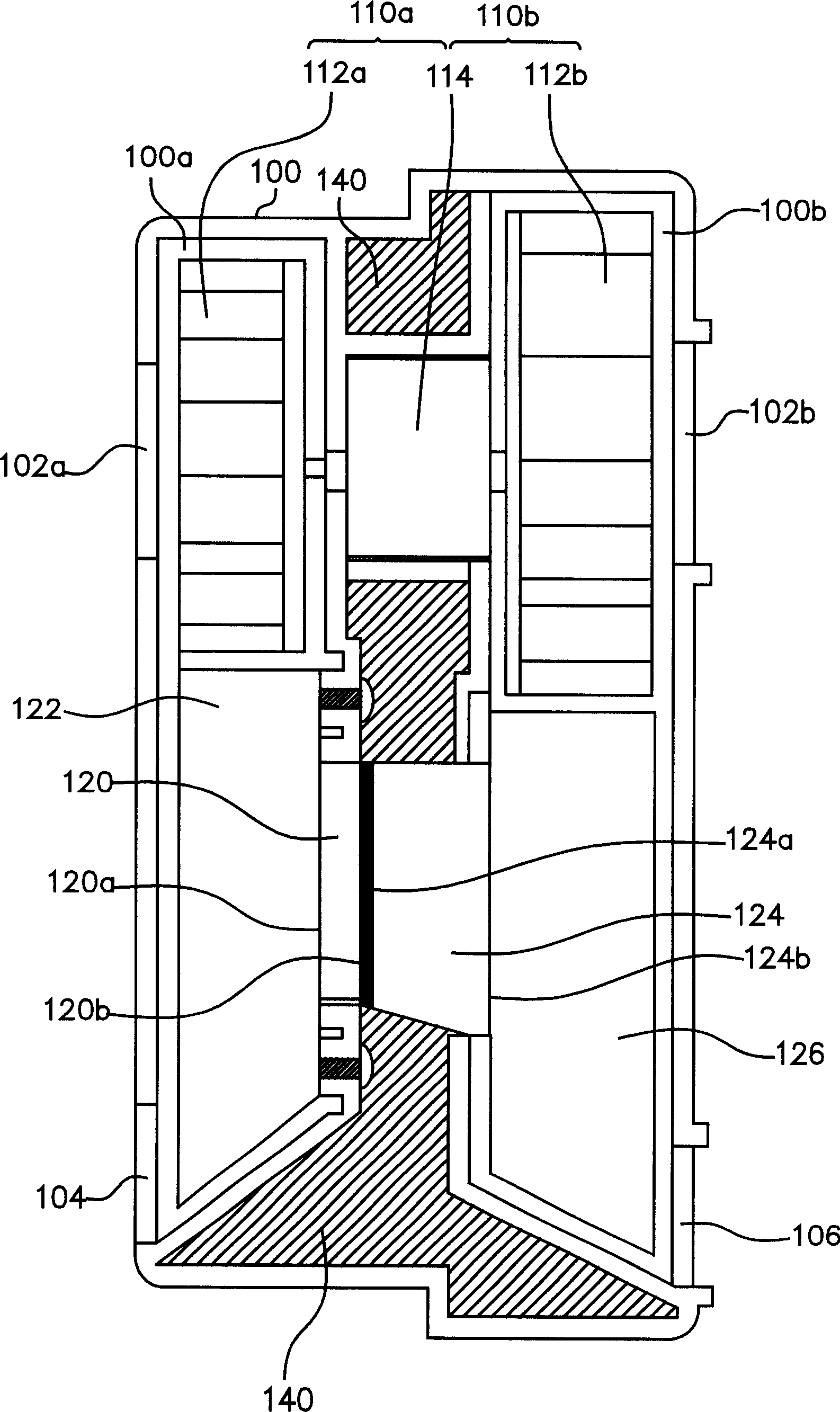

[0034] see Figures 1A to 1C , Figure 1A , 1B A front view and a rear view of a preferred embodiment of a cooling device with cooling and heat exchanging functions according to the present invention are shown respectively. Figure 1C for Figure 1A side profile view. The heat dissipation device with heat exchange function mainly includes a housing 100 , a first flow guiding device 110 a , a cooling chip 120 and a second flow guiding device 110 b.

[0035] The casing 100 includes a first space 100 a with a first air inlet 102 a and a cold air outlet 104 , and a second space 100 b with a second air inlet 102 b and a hot air outlet 106 . The first flow guiding device 110a is located next to the first air inlet 102a, and is used to guide a heat source fluid to enter the housing 100 from the first air inlet 102a, the heat source fluid flows out of the housing from the cold air outlet after being cooled, and the external environment fluid passes through After heat exchange, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com