A kind of method of powder sintering preparation Al-SN base bearing alloy

A powder and alloy technology, which is applied in the field of Al-Sn-based bearing alloy preparation, can solve the problems of easy water absorption, high hardness of nanocrystalline powder, difficult bonding strength, etc., and achieve the effect of high activity and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

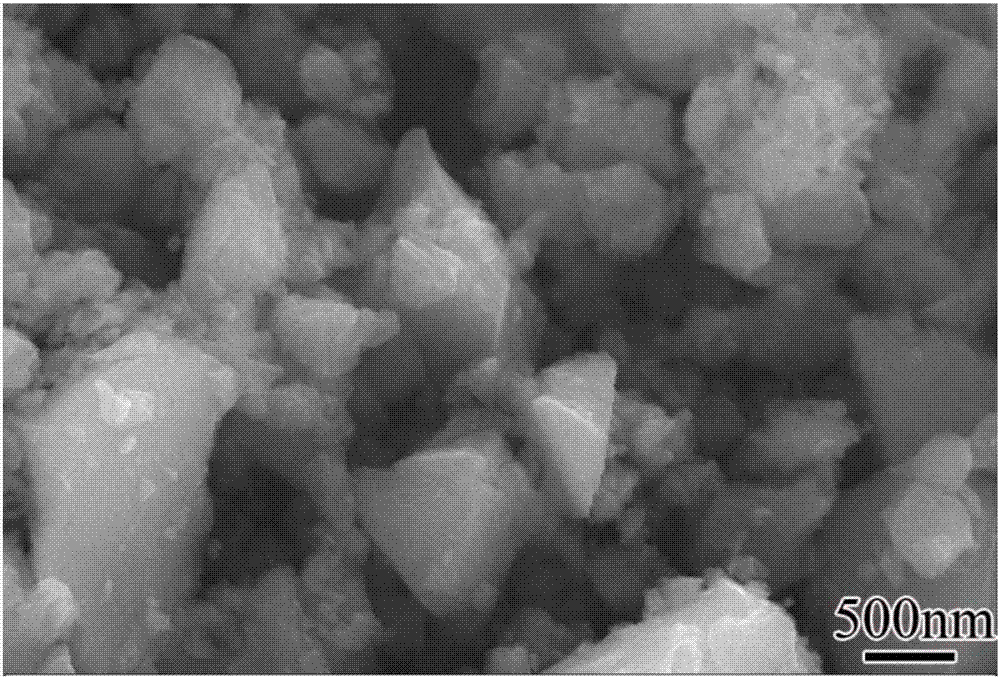

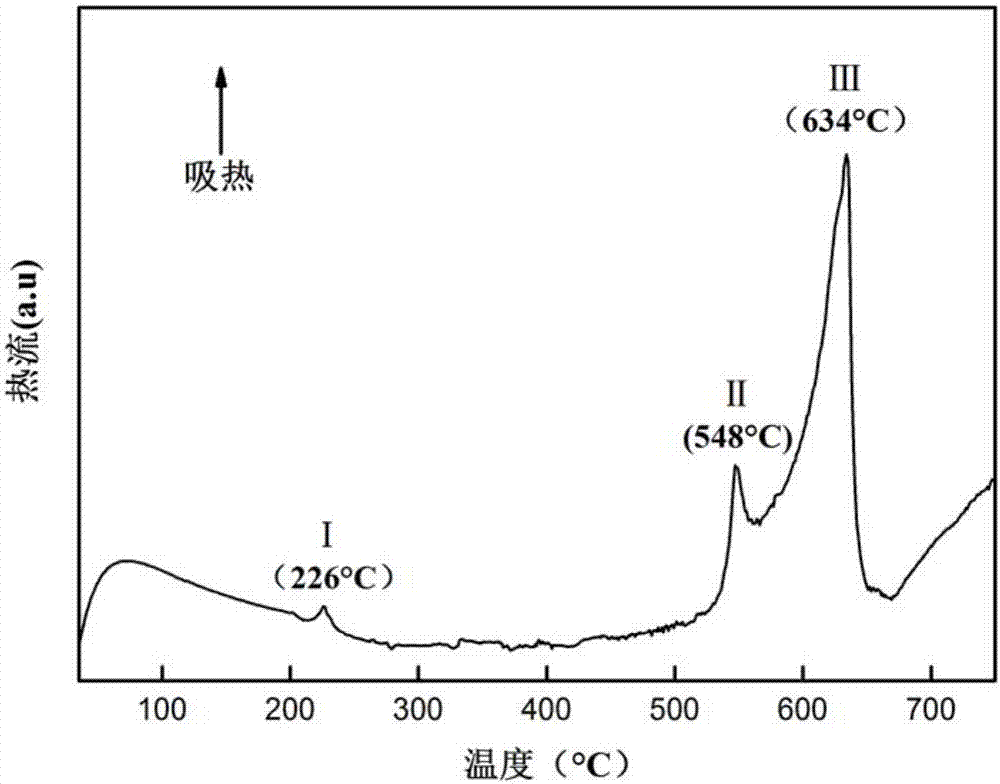

[0046] (1) The silicon powder with a particle size of 40-200 mesh and a purity of 99.5% is refined by a plasma discharge-assisted ball mill under the protection of argon, the discharge current is 1.5A, the ball milling time is 4h, and the abrasive ratio is 50:1 ; The surface morphology of the obtained Si powder is as follows figure 1 shown.

[0047] (2) the particle size is 200 orders, the aluminum powder that is 99.5% of purity, Si powder and the Si powder after step (1) process are mixed evenly by Al-12%Sn-2.5%Si mass percent, adopt under argon protection QM-2SP planetary ball mill is used for ball milling, the ball milling speed is 350rpm / min, the ball milling time is 40h, and the ball-to-material ratio is 15:1 to obtain nanocrystalline Al-12%Sn-2.5%Si alloy powder;

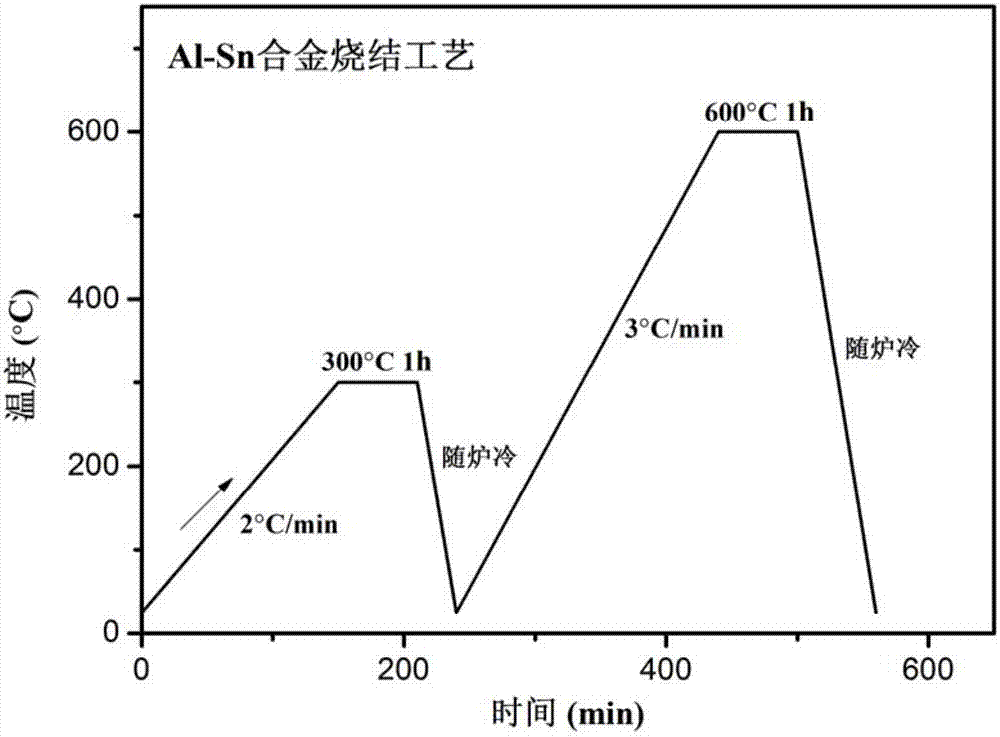

[0048] (3) taking by weighing 4g of the nanocrystalline Al-Sn alloy powder gained in step (1) and packing it into a mold with a diameter of 24mm, using a universal hydraulic material testing machine to pre-pr...

Embodiment 2

[0053] (1) The silicon powder with a particle size of 40-200 mesh and a purity of 99.5% is refined by a plasma discharge-assisted ball mill under the protection of argon, the discharge current is 1.5A, the ball milling time is 4h, and the abrasive ratio is 50:1 ; The surface morphology of the obtained Si powder is as follows figure 1 shown.

[0054] (2) the particle size is 200 orders, the aluminum powder that is 99.5% of purity, Si powder and the Si powder after step (1) process are mixed evenly by Al-12%Sn-2.5%Si mass percent, adopt under argon protection QM-2SP planetary ball mill is used for ball milling, the ball milling speed is 350rpm / min, the ball milling time is 40h, and the ball-to-material ratio is 15:1 to obtain nanocrystalline Al-12%Sn-2.5%Si alloy powder;

[0055] (3) taking 4g of the nanocrystalline Al-Sn alloy powder gained in step 1 and packing it into a mold with a diameter of 24mm, and using a universal hydraulic material testing machine to pre-press into a...

Embodiment 3

[0061] The procedure of this example is basically the same as that of Example 2, except that the cold-rolled alloy block is subjected to recrystallization annealing at 400°C, the heating rate is 3°C / min, the holding time is 1h, and it is cooled with the furnace to obtain sample 3. , the surface morphology is shown in Figure 5(c), and the fracture morphology is shown in Figure 6(c).

[0062] Test its mechanical properties: the density of the alloy is 99.3%, the hardness is 80HV, the tensile strength is 233MPa, and the elongation is 3.5%.

[0063] The performance characterization results of the Al-Sn-based bearing alloy prepared in this example are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com