Mathematics high-precision measuring tool processing device

A processing device and high-precision technology, which is applied in metal processing equipment, workpieces, manufacturing tools, etc., can solve problems such as measuring tool burrs, and achieve the effects of simple manufacturing process, uniform dispersion, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

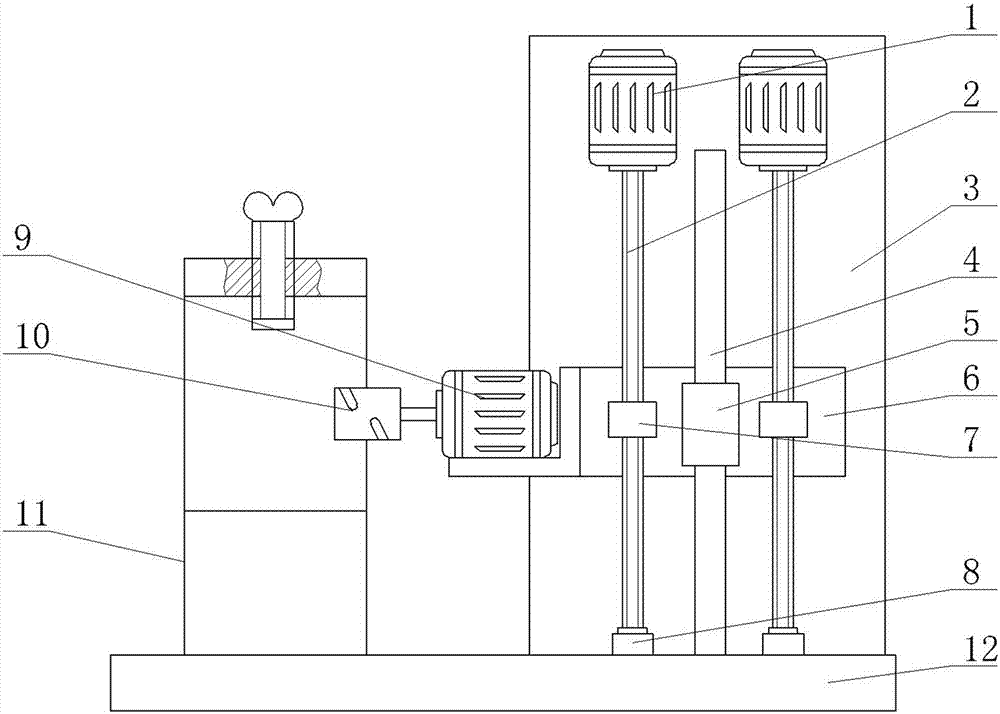

[0024] Embodiment Mathematics high-precision measuring tool processing device

[0025] Such as figure 1 As shown, the present embodiment includes a base 12, a fixture 11, a guide rod 4 and a fixed mount 3 are installed on the top of the base 12, and two stepper motors 1 are installed on the top of the fixed mount 3, and the output shaft of the stepper motor 1 is vertically downward. There is a distance between the output shafts of the two stepper motors 1, the guide rod 4 is located between the output shafts of the two stepper motors 1, the guide rod 4 is in a vertical state, and the lifting milling device is installed on the screw mandrel 2, the described The lifting milling device includes a lifting plate 6, two fixed pipes 7 and a guide pipe 5 are installed on the lifting plate 6, the inside of the fixed pipe 7 is provided with internal threads, the fixed pipe 7 is threaded with the screw rod 2, and the guide pipe 5 is set on the guide tube. A rotating motor 9 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com