A bin structure for a coating machine

A technology of coating machine and silo, applied in the field of coating machine, can solve the problems of improving the labor intensity of workers, burns, time-consuming and laborious, etc., and achieves the effects of improving precise control, preventing burns, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below.

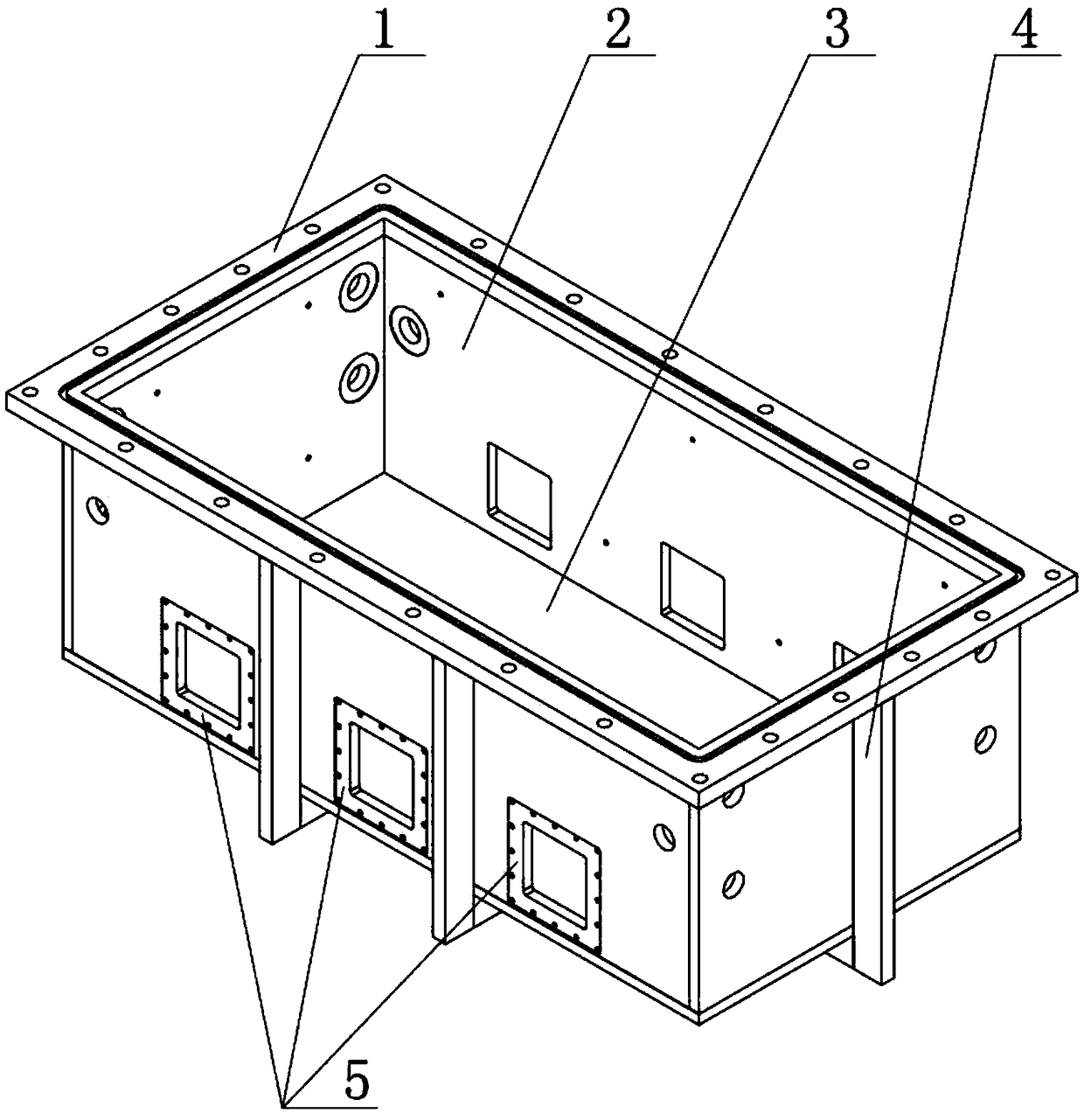

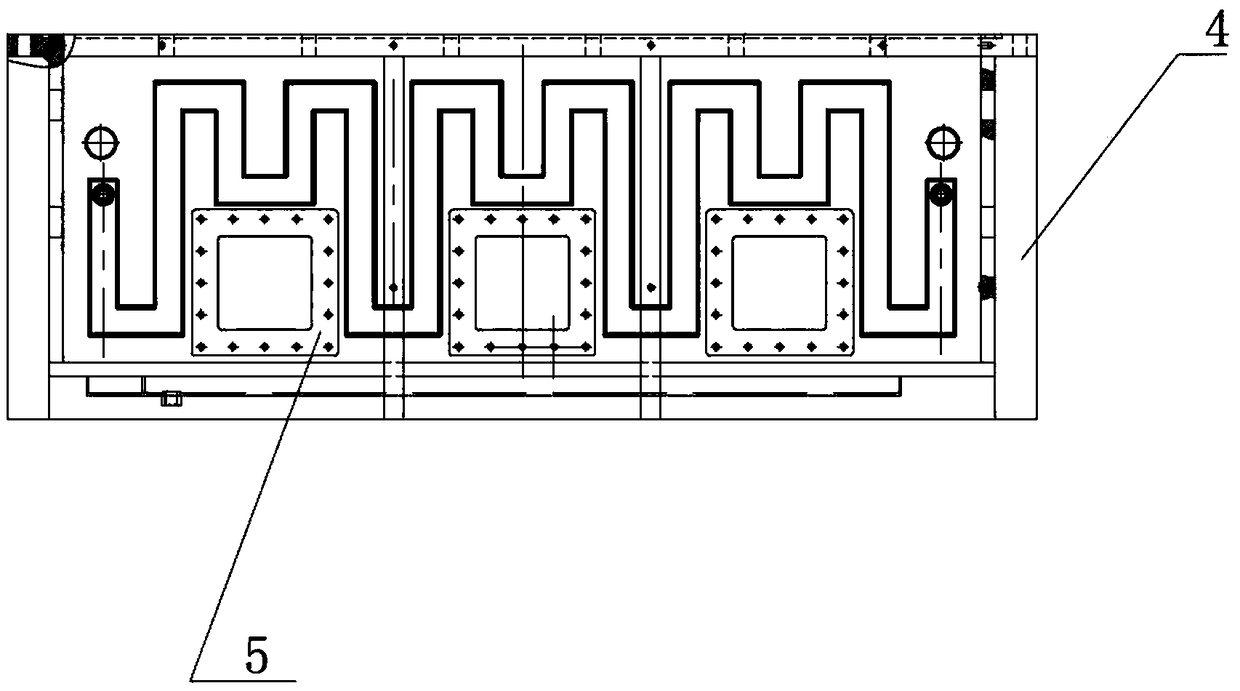

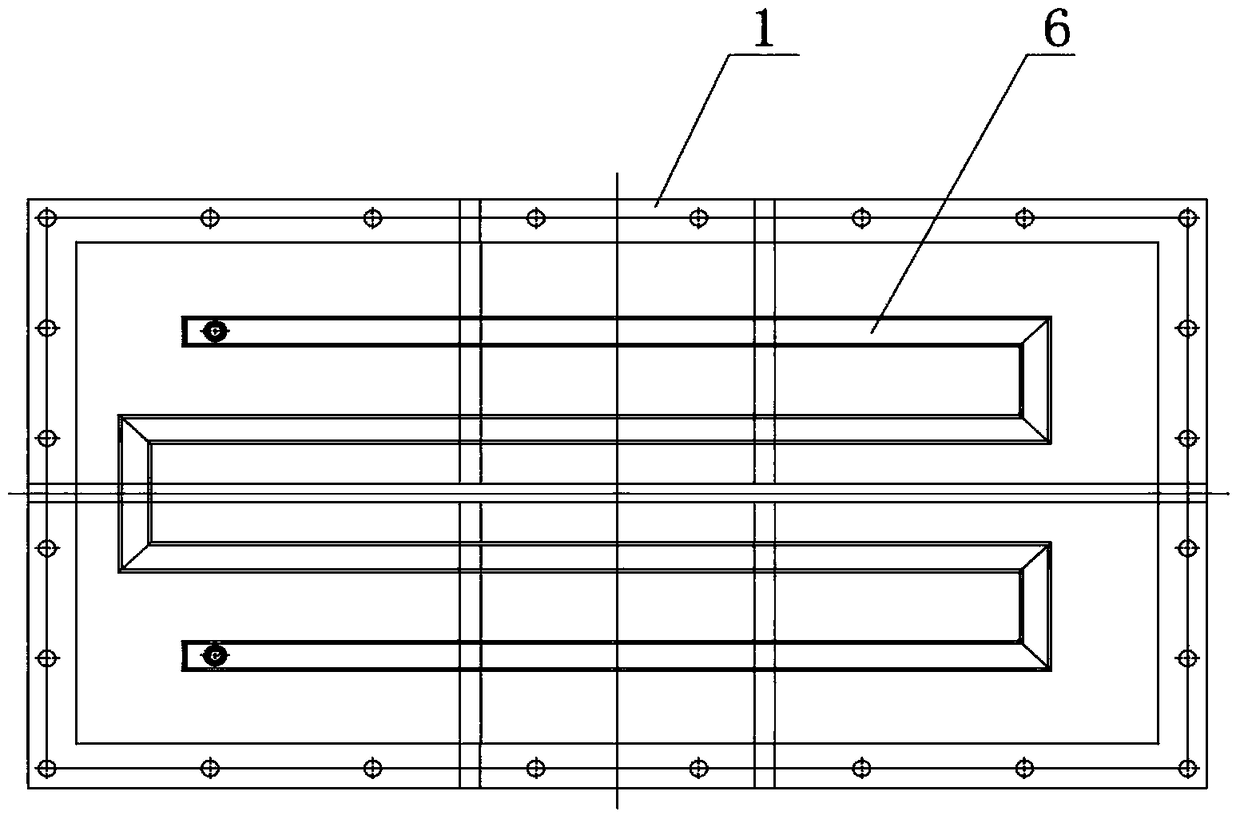

[0023] Such as Figure 5 , Image 6 As shown, a silo structure for a coating machine according to the present invention includes a silo body, the silo body is slidably connected with the guide rail 10 through rollers 13, and a plurality of cylinders 12 are arranged at the bottom of the silo body. The two ends of each are respectively provided with a first traction mechanism 8 and a second traction mechanism 9 for pulling the bin body on the guide rail for linear displacement. The above-mentioned cylinders 12 are respectively located at the front end and the rear end of the bottom of the silo body, and the cylinders 12 are used to lift the silo body and realize the communication between the silo body and the coating chamber 7 . Such as Figure 4 As shown, the above-mentioned first traction mechanism 8 and the second traction mechanism 9 both include a motor, a traction belt and a hook, the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com