A sheet pile wall structure for decompression and anti-seismic

A sheet pile wall and sheet pile technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of easy bending, deformation, damage, and the lack of earthquake resistance of sheet pile walls, so as to reduce soil pressure. , The effect of protecting soil structure and uneven settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

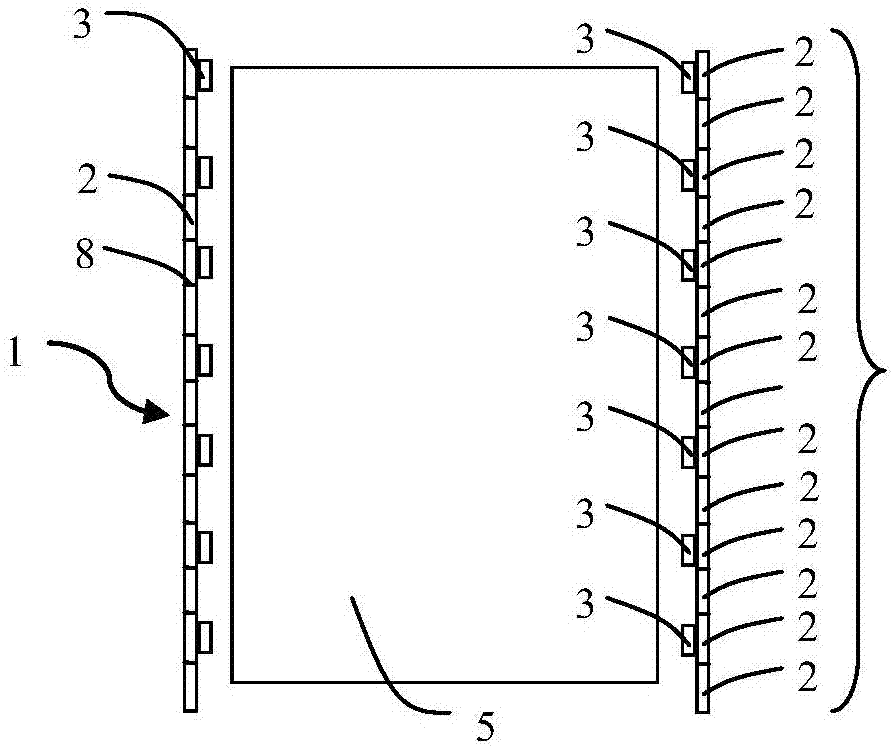

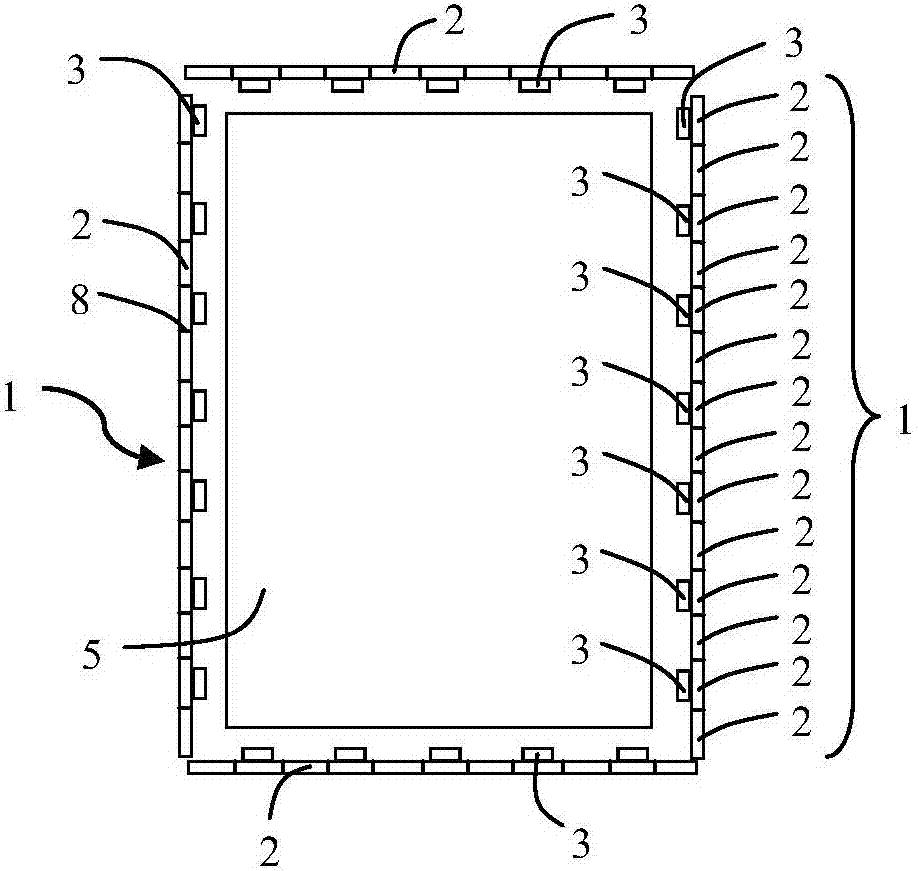

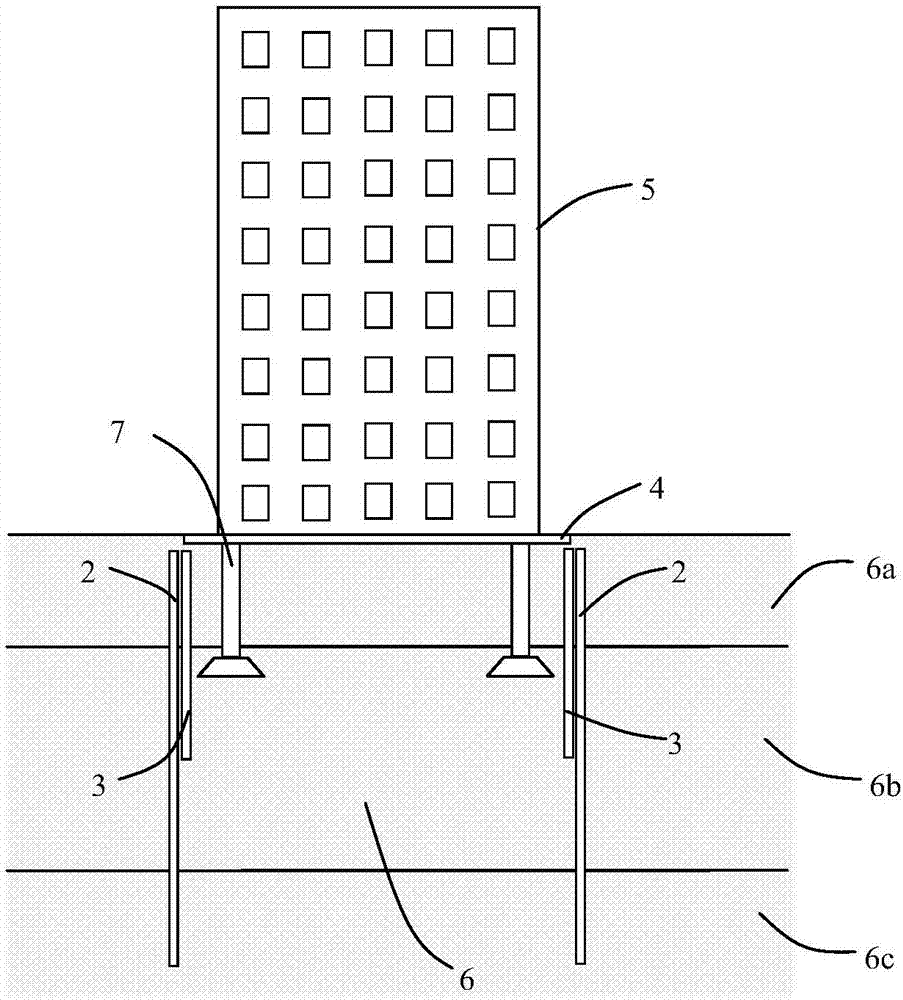

[0027] A decompression and anti-seismic sheet pile wall structure, comprising a sheet pile wall 1 composed of a plurality of sheet piles 2 arranged in a row, an elastic body 3, and a base plate 4, the material of the sheet pile 2 is a steel plate, and the adjacent plate The piles 2 are connected together by joint joints 8; there are two sheet pile walls 1, which are arranged symmetrically along the length direction of the building; The plane is 0.5m, through the core soil layer 6b, and then inserted into the subsoil layer 6c, the elastic body 3 is arranged on the inner side of the sheet pile 2, the upper end is flush with the sheet pile 2, and the lower end is in the core soil layer 6b. A plurality of drainage holes 9 are evenly arranged on the elastic body 3, including horizontal drainage holes and vertical drainage holes, which can drain water to relieve the pressure in the soil layer. The material of the elastic body 3 is foamed resin, which has light weight , the advantage...

Embodiment 2

[0035] A decompression and anti-seismic sheet pile wall structure, comprising a sheet pile wall 1 composed of a plurality of sheet piles 2 arranged in a row, an elastic body 3, and a base plate 4, the material of the sheet pile 2 is reinforced concrete, and the relative The adjacent sheet piles 2 are connected together by joint joints 8; there are four sheet pile walls 1, which are arranged symmetrically along the length and width directions of the building; The layer 6a is 1m away from the ground surface, passes through the core soil layer 6b, and then inserts into the subsoil layer 6c, the elastic body 3 is arranged on the inside of the sheet pile 2, the upper end is flush with the sheet pile 2, and the lower end is in the core soil layer 6b Inside, the elastic body 3 is evenly provided with a plurality of drainage holes 9, including horizontal drainage holes and longitudinal drainage holes, which can drain water and relieve the pressure in the soil layer. The material of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com