Split mounting type steel suspension box

A steel hanging box, assembled technology, applied in caisson, construction, infrastructure engineering and other directions, can solve problems such as increasing construction workload and water leakage, and achieve the effect of improving water retaining effect, reducing construction cost, and smoothing the processing surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

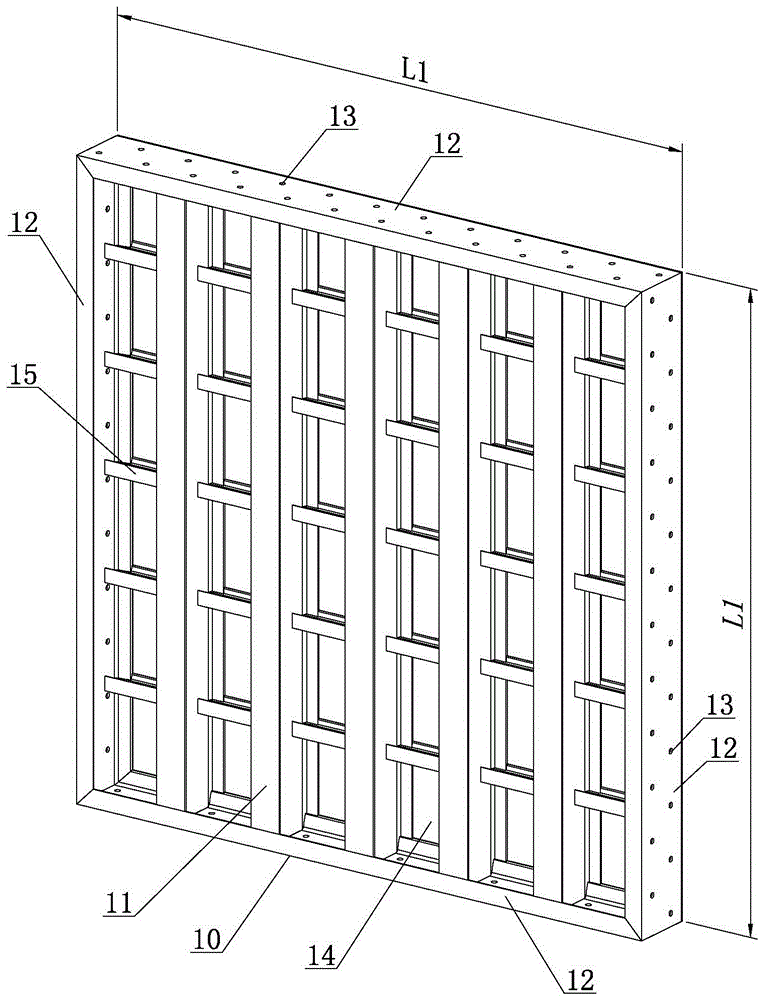

[0037] Such as figure 2 , a direct connection unit side panel 10, the direct connection unit side panel is a unit side panel with a rectangular panel 14, and the side length of the direct connection unit side panel is L1=3000mm.

[0038] The side plate of the direct connection unit is provided with 5 vertical vertical beams 11, the vertical vertical beams are H-shaped steel with a height of 300mm, and horizontal beams 15 are also arranged between the vertical vertical beams, and the horizontal beams adopt 10# I-beam.

[0039] The four sides of the side plates of the direct connection units are provided with unit plate connection sides 12, and the four sides of the side plates of the direct connection units are straight connection sides. The straight connecting sides are welded to the vertical beams and beams to form a frame with high rigidity. The end face of the straight connection side is perpendicular to the panel of the unit side panel.

[0040] The connecting edge of ...

Embodiment 2

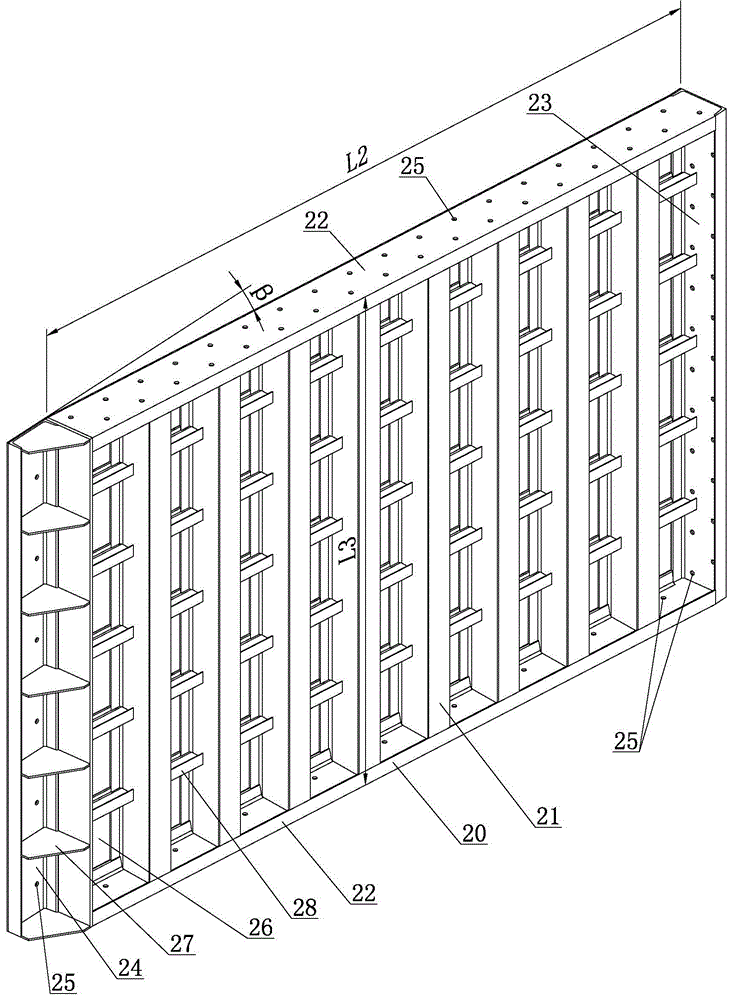

[0043] Such as image 3 , a corner connection unit side panel 20, the corner connection unit side panel is a 26-bit rectangular unit side panel, the length of the corner connection unit side panel is L2=4568mm, and the height L3=300mm.

[0044] The side plate of the corner connection unit is provided with 8 vertical vertical beams 21, the vertical vertical beams are H-shaped steel with a height of 300mm, and horizontal beams 28 are also arranged between the vertical vertical beams, and the horizontal beams adopt 10# I-beam.

[0045] The upper and lower sides of the corner connection unit side plate are straight connection edges 22, and one side of the corner connection unit side plate is an oblique connection edge 23, the straight connection edge is welded to the vertical beam, and the oblique connection edge is welded to the crossbeam. The end face of the straight connection side is perpendicular to the panel of the unit side panel. There is an inclination angle α=83.26° be...

Embodiment 3

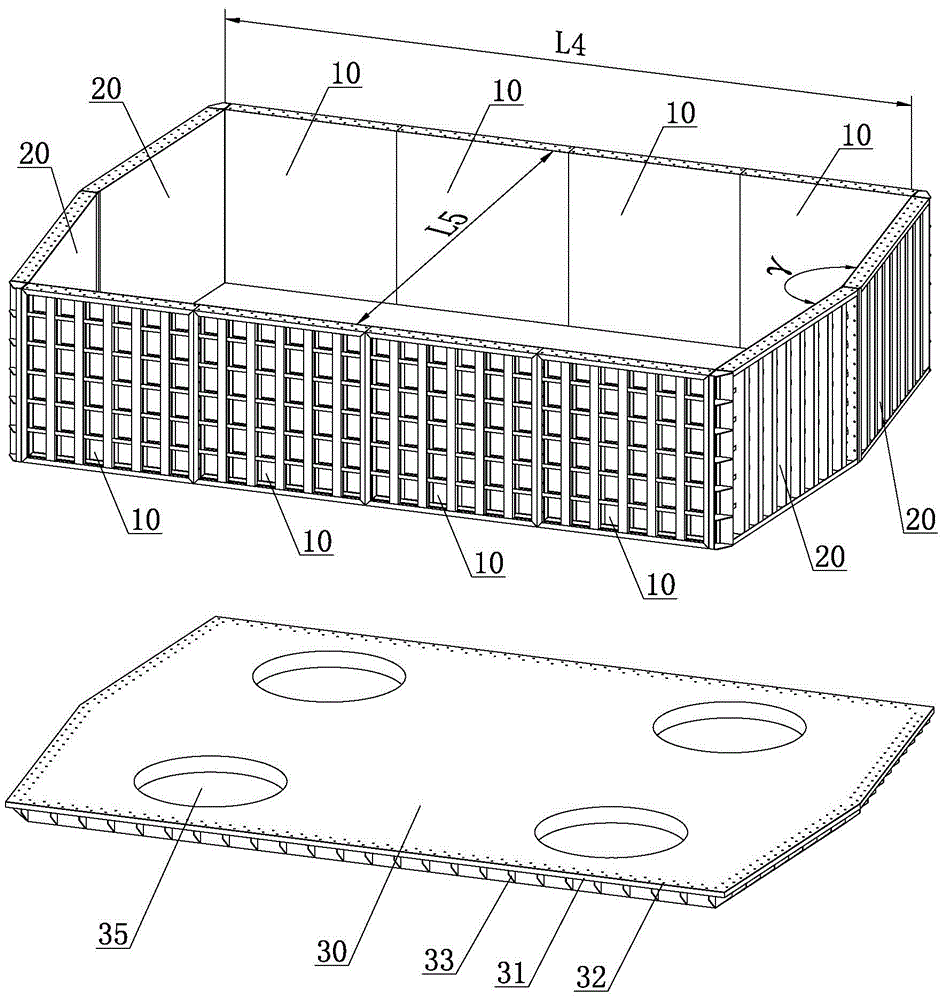

[0049] Such as Figure 1 to Figure 8 , an assembled steel hanging box, including side walls and a bottom plate. The steel casing has two straight side walls and four inclined side walls, the length of the two straight side walls is L4=12000mm, and the distance between the two straight side walls is L5=9080mm. The two ends of the two straight side walls are respectively connected to a sloped side wall, and the two sloped side walls at each end are connected to each other, and the connection is protruding outward, and the apex angle of the protruding part is γ=166.52°. The height of the assembled steel hanging box is L6=90000mm.

[0050] Each straight side wall is composed of the straight connection unit side panels 10 described in Embodiment 1 of 12. There are 4 straight connection unit side panels arranged in the horizontal direction and 3 straight connection unit side panels in the vertical direction, forming two sides 12m long and 9m long. Tall straight side walls. The un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com