Prefabricated steel-plastic composite underground comprehensive pipe gallery

A steel-plastic composite and comprehensive pipe gallery technology, which is applied to underwater structures, artificial islands, and infrastructure engineering, can solve problems such as inconvenient maintenance for staff, messy pipeline laying, and increased failure risks, and achieve overall structural strength High, reduce construction difficulty, improve the effect of construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

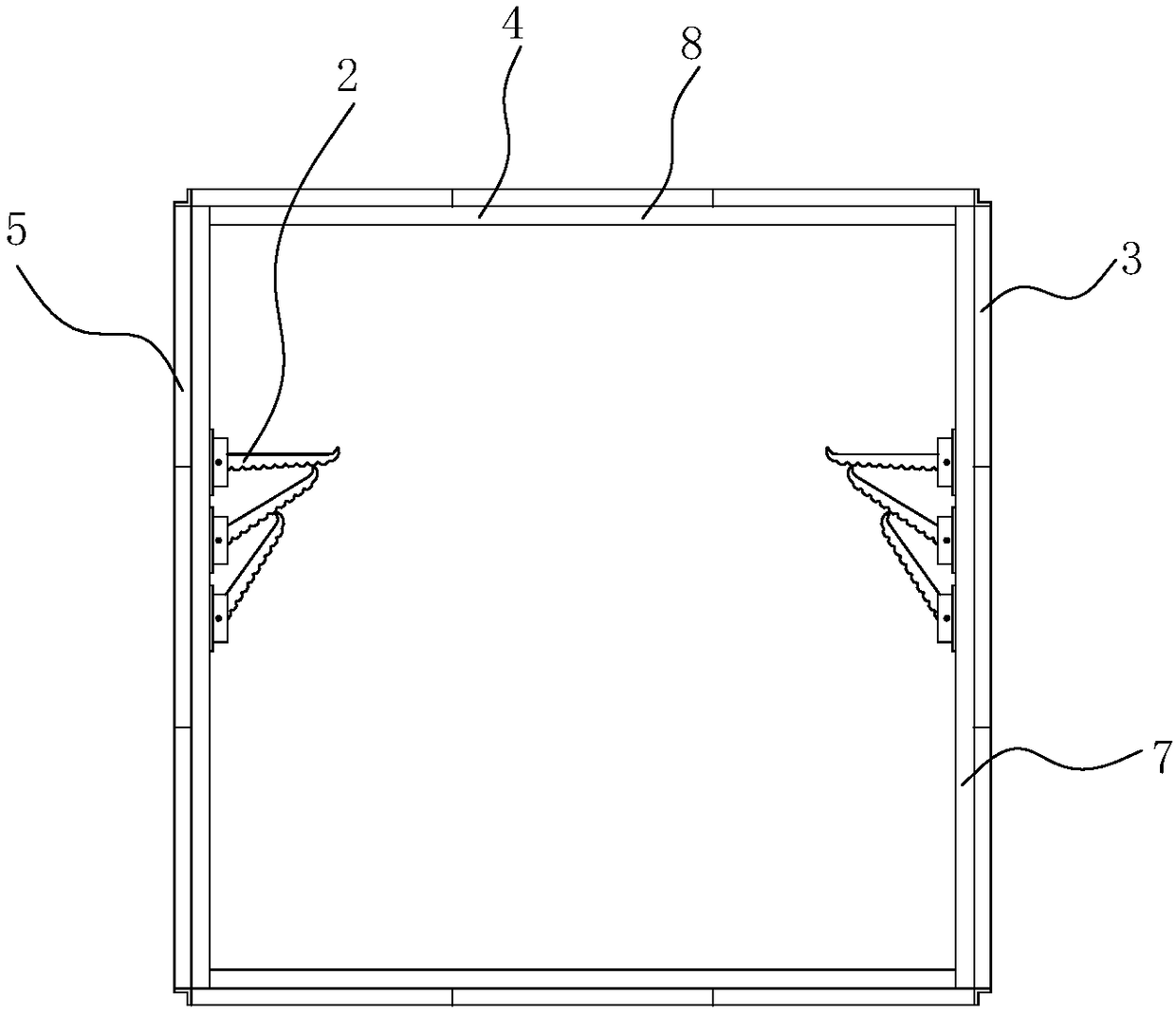

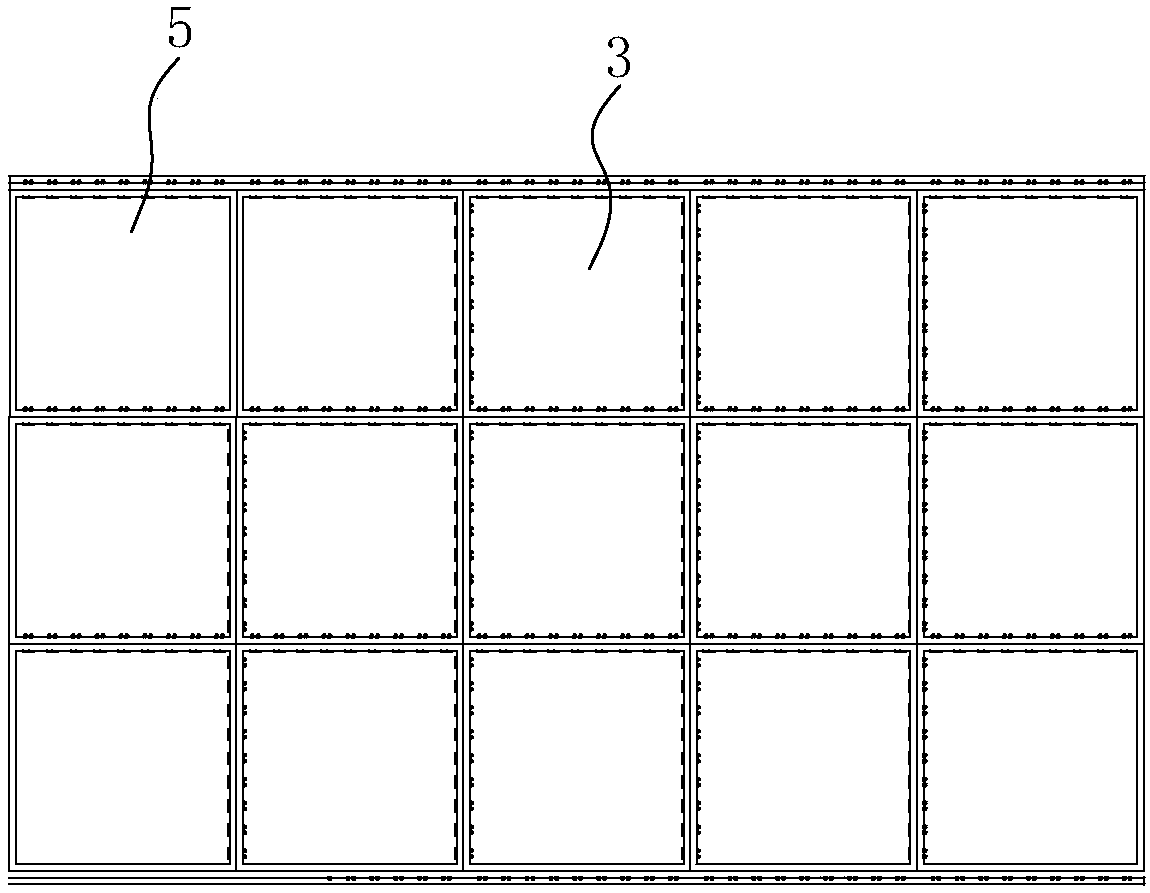

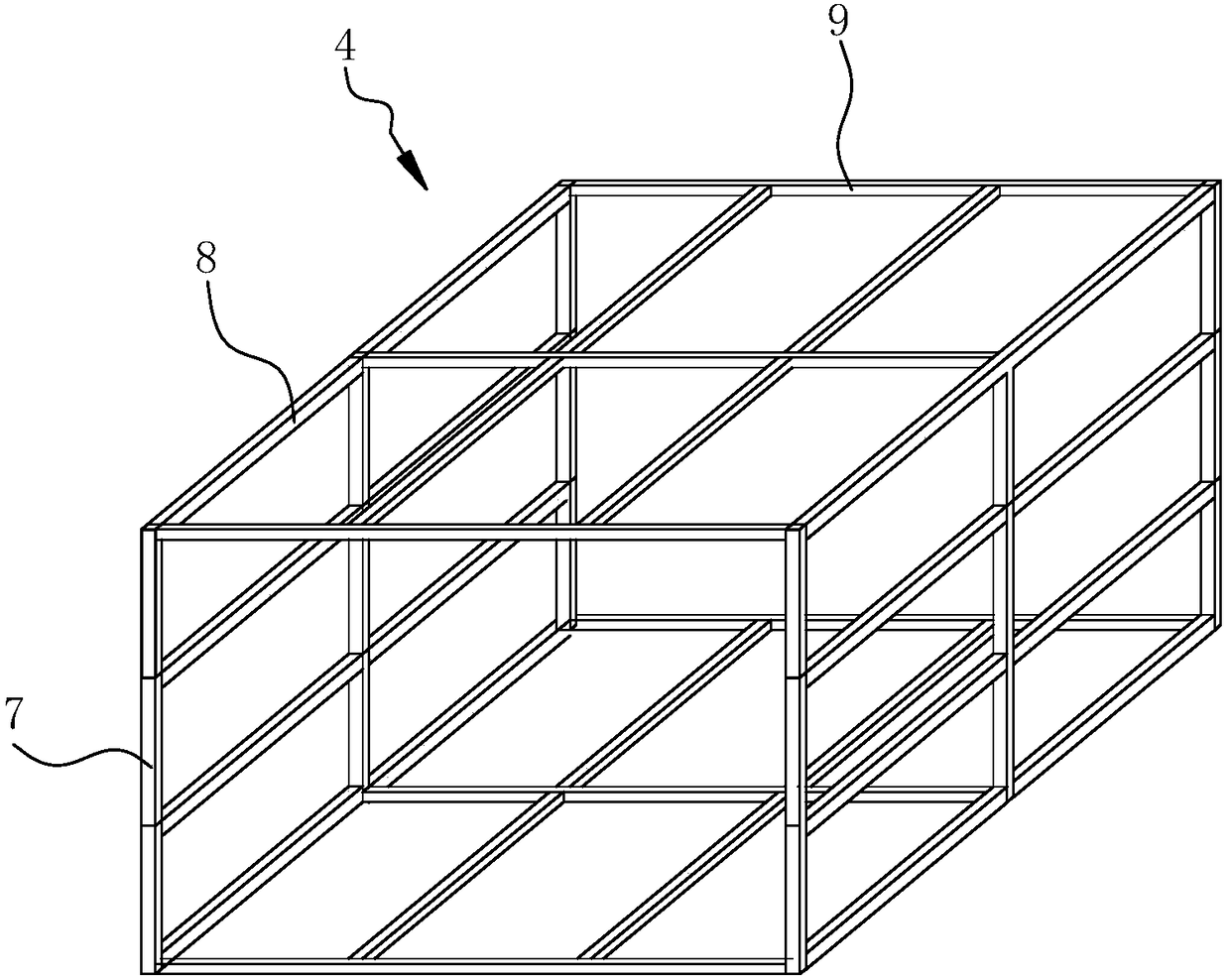

[0028] combine Figure 1-11 The prefabricated steel-plastic composite underground comprehensive pipe gallery shown includes the main body of the tunnel and several brackets 2 located inside the main body. The area without brackets 2 inside the main body of the tunnel can be used for laying drainage pipe networks, gas pipe networks, cable pipe networks, etc. The same support 2 can also be used for laying drainage pipe network, gas pipe network, cable pipe network and the like. The simplest bracket 2 is a plurality of horizontal rods located inside the main body, on which cables, wire ducts or various pipes can be placed, and the bracket 2 can also be a wire slot fixedly laid along the inner wall of the main body or other devices that play the same role structure. The main body includes a shell 3 and a skeleton 4 positioned on the inner wall of the shell 3, such as figure 2 As shown, the shell 3 is formed by splicing a plurality of square panels 5, and the square panels 5 hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com