Assembly method of prefabricated integral assemble type portable house

A prefabricated house and assembled technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of waterproof and sound insulation, poor corrosion resistance and shock resistance, etc., achieve good thermal insulation effect, convenient and quick assembly and disassembly , The effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

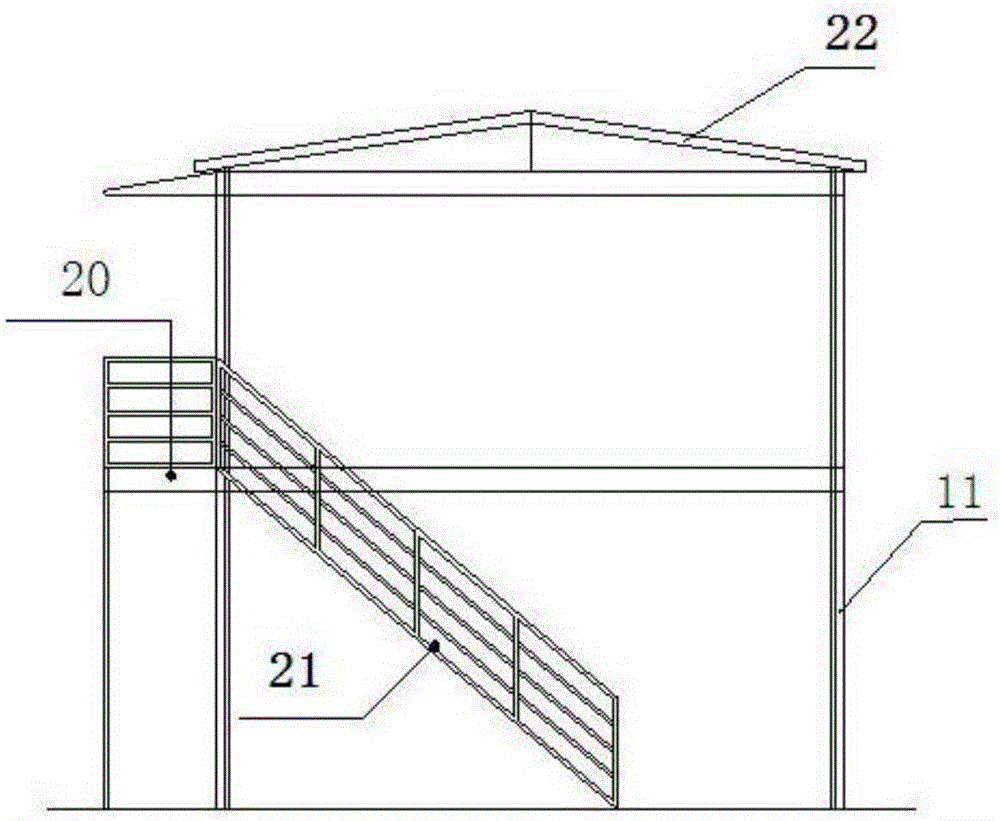

[0040] Such as figure 1 Shown, a kind of assembling method of prefabricated overall assembled prefabricated prefabricated prefabricated house, is to have prefabricated wall unit 11, prefabricated floor unit 20, railing 21, roof 22 and accessory components such as door, window to disassemble and assemble. in Figure 6 Point A in the middle is marked as the position of vertically connected embedded parts.

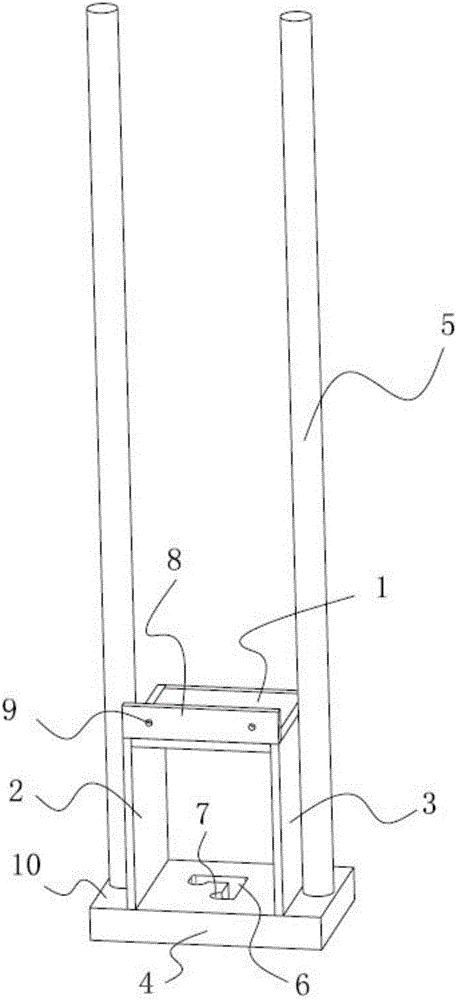

[0041] Among them, the prefabricated wall unit is a reinforced concrete structure, the upper end of the prefabricated wall unit 11 is pre-embedded with lifting point embedded parts, the lower end of the prefabricated wall unit is pre-embedded with vertical connection embedded parts, and the prefabricated wall unit is close to the left and right sides. The side is pre-embedded with screw embedded parts.

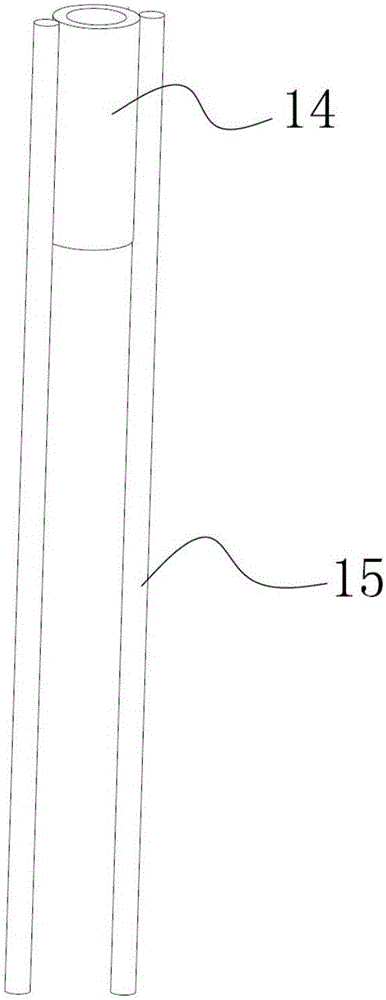

[0042] Such as image 3 As shown, the embedded part of the lifting point includes an internally threaded sleeve 14, and the outer wall of the internally threaded sleeve 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com