Hydraulic climbing mold fully automatic climbing system and its control method

A hydraulic climbing formwork and control method technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of large safety hazards and low construction efficiency, and achieve improved safety and improved The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

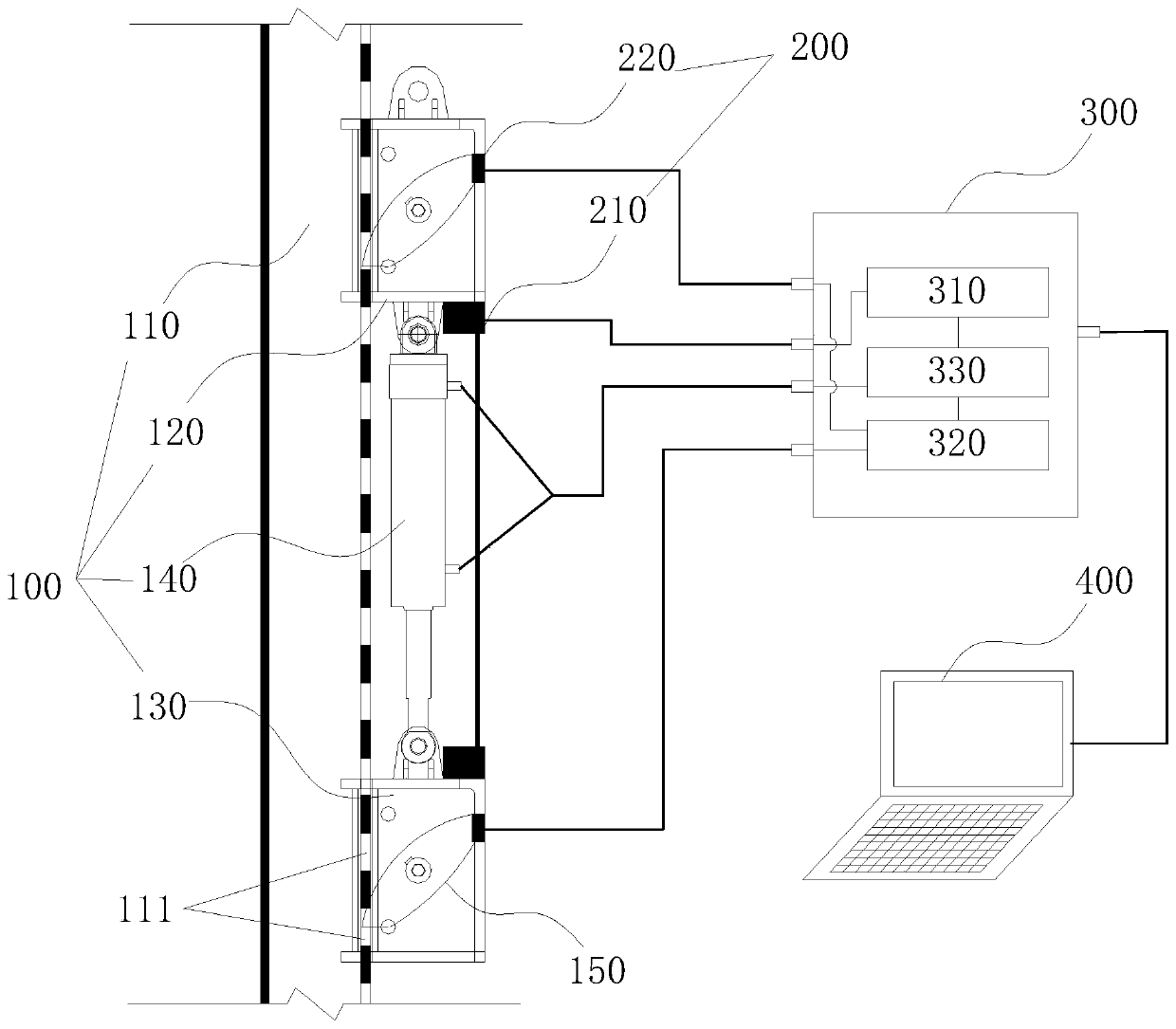

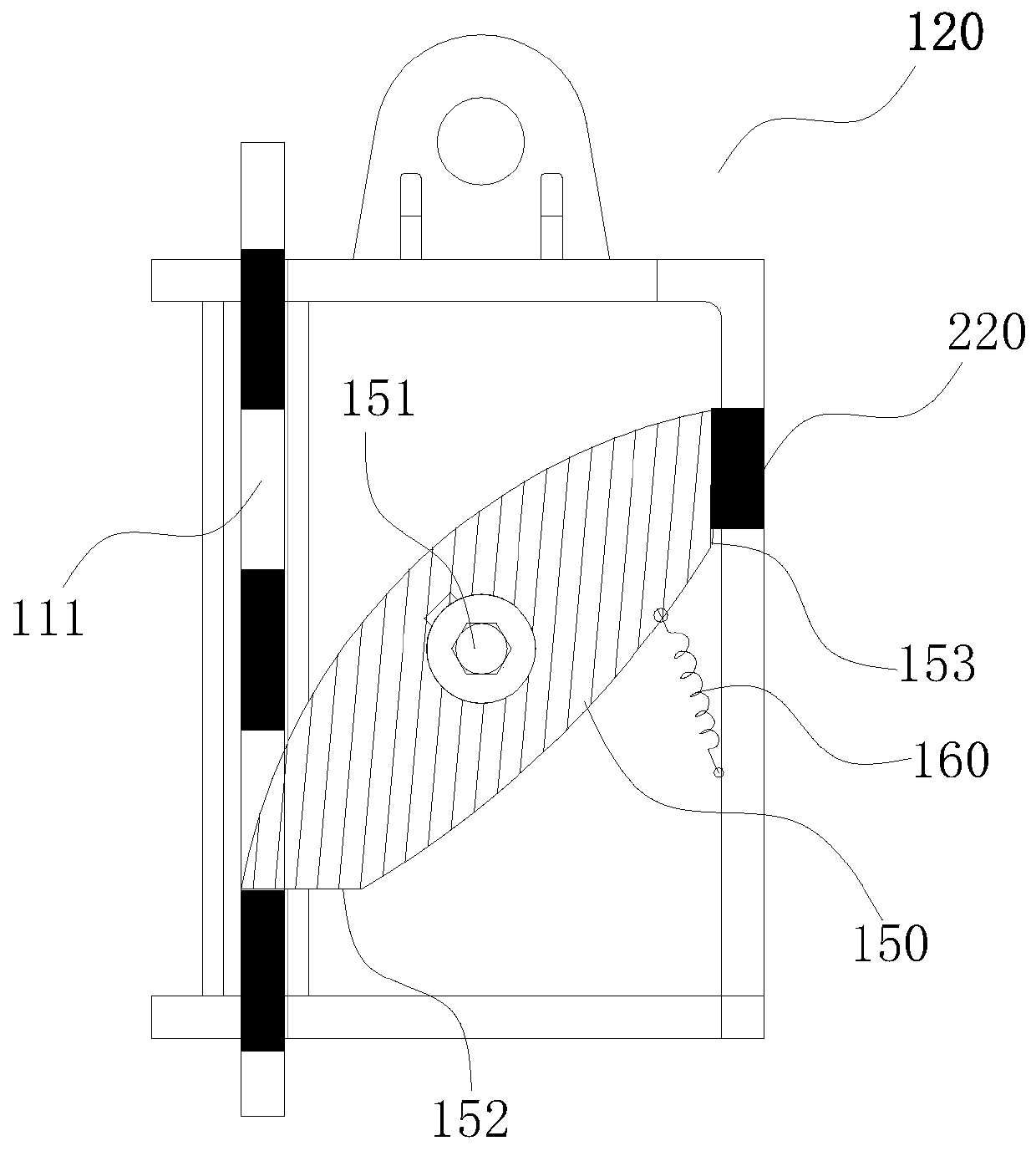

[0042] see Figure 2 to Figure 4 ,in figure 2 A schematic structural view of the hydraulic climbing formwork automatic climbing system provided in this embodiment, image 3 is a schematic diagram of the structure of the upper fall arrester in a static state, Figure 4 It is a structural schematic diagram of the upper fall arrester during climbing. The following will combine Figure 2 to Figure 4 The gist of the present invention is further described.

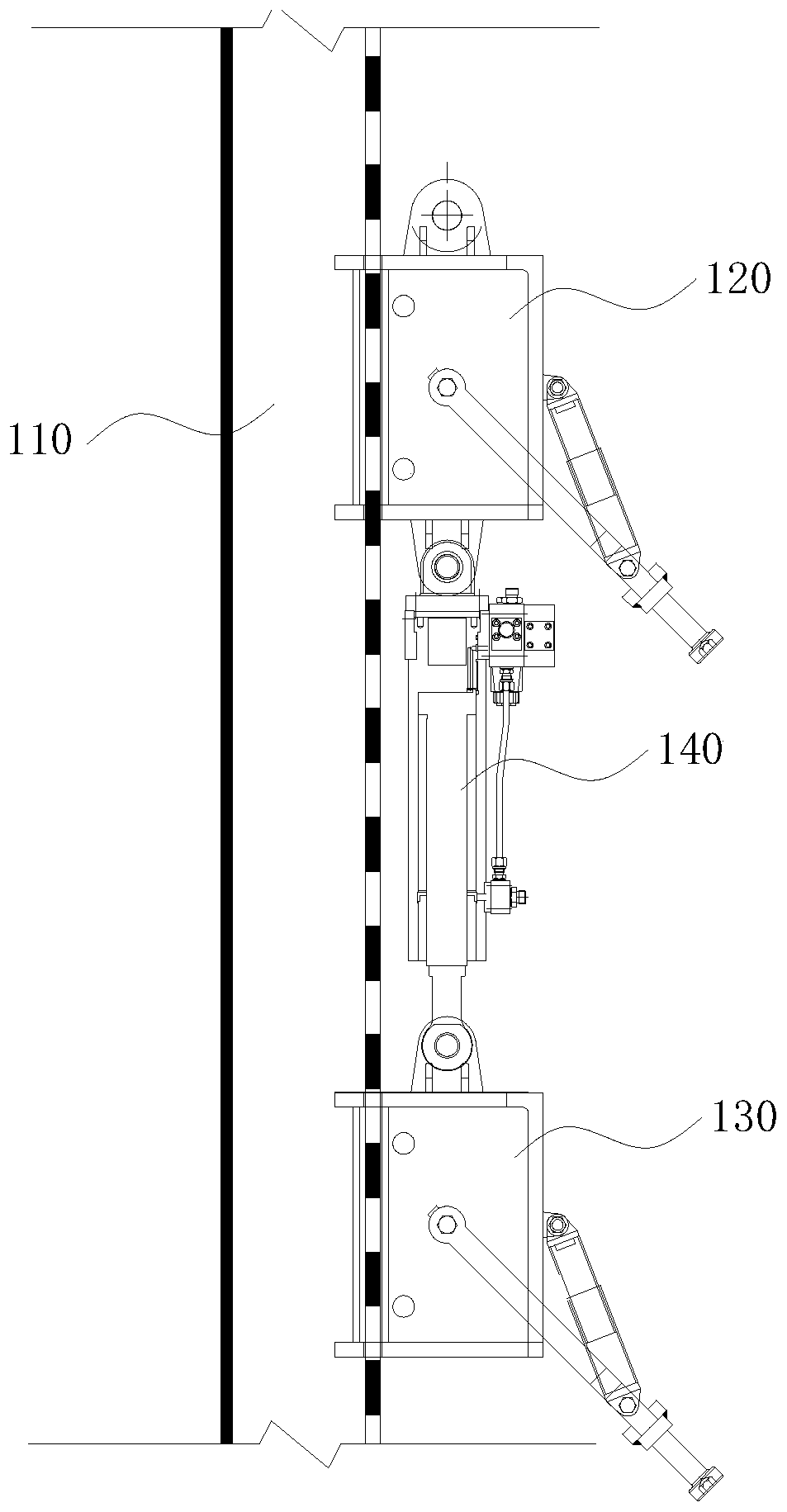

[0043] Such as figure 2As shown, a hydraulic climbing mold automatic climbing system includes a hydraulic mechanical system 100 , a digital sensor system 200 and a climbing control system 300 . Among them, the hydraulic mechanical system 100 includes a guide rail 110, an upper anti-fall device 120, a lower anti-fall device 130, and a hydraulic cylinder 140. The guide rail 110 is provided with a clamping hole 111, and the upper anti-fall device 120 and the lower anti-fall device 130 are attached to the guide rail 110. The...

Embodiment 2

[0051] see Figure 5 , and combined with Figure 2-4 The control method of the hydraulic climbing mold fully automatic climbing system is further explained. The control method of the hydraulic climbing mold fully automatic climbing system includes the following steps:

[0052] S1: Turn on the automatic climbing system of the hydraulic climbing mold and start the climbing operation.

[0053] S2: The hydraulic cylinder controller 330 controls the hydraulic cylinder 140 to carry out cylinder extension operation, the jaw 150 of the lower anti-fall device 130 is located in the clamping hole 111, and acts as a holding end, and the hydraulic cylinder 140 lifts the jaw 150 of the upper anti-fall device 120 to the top At the position of a clamping hole 111 , the claw 150 of the upper anti-fall device springs into the clamping hole 111 , and at the same time, the "0-1" signal transmitter 220 on the upper anti-fall device 120 sends out a "1" signal. The initial state of the cylinder e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com