High precision intelligent gas pressure source

A gas pressure, high-precision technology, used in the measurement of fluid pressure, instruments, measuring devices, etc., can solve the problems of inportability, inability to intelligent, large pressure source, etc., and achieve the effect of reducing vibration, wide pressure range, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

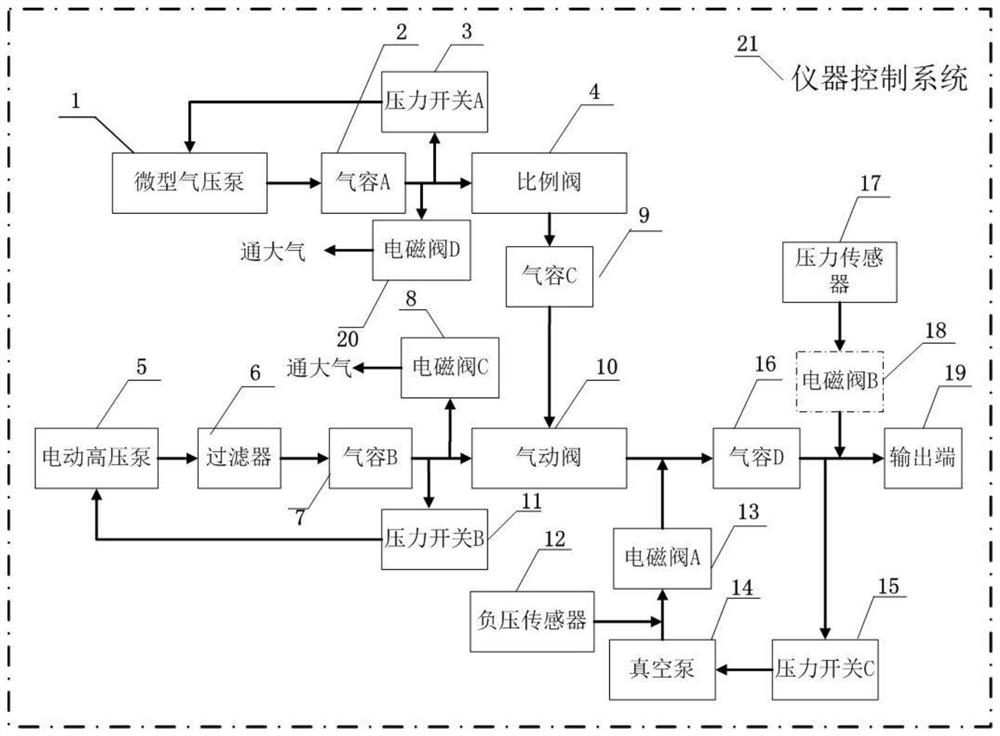

[0047] like figure 1 As shown, this embodiment discloses a high-precision intelligent gas pressure source of the present invention, including a micro air pressure pump 1, a gas capacity A2, a pressure switch A3, a proportional valve 4, an electric high pressure pump 5, a filter 6, a gas capacity B7, and a solenoid valve. C8, air capacity C9, pneumatic valve 10, pressure switch B11, negative pressure sensor 12, solenoid valve A13, vacuum pump 14, pressure switch C15, air capacity D16, pressure sensor 17, solenoid valve B18, output 19, solenoid valve D20, Instrument Control System 21 .

[0048] Among them, the micro air pressure pump 1, the air volume A2, the pressure switch A3 and the proportional valve 4 together form the driving source part of the pneumatic valve 10, which provides the driving source for the pneumatic valve 10 of the positive pressure output passage; the electric high pressure pump 5, the filter 6, Gas volume B7, solenoid valve C8, gas volume C9, pneumatic v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com