Technical scheme for preparing slurry for crushed soft formation for downhole drilling

A technical solution, mud technology, applied in earthwork drilling, flushing wellbore, wellbore/well parts, etc., can solve problems such as difficulties, achieve the effects of reducing waste, improving drilling efficiency and drilling engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

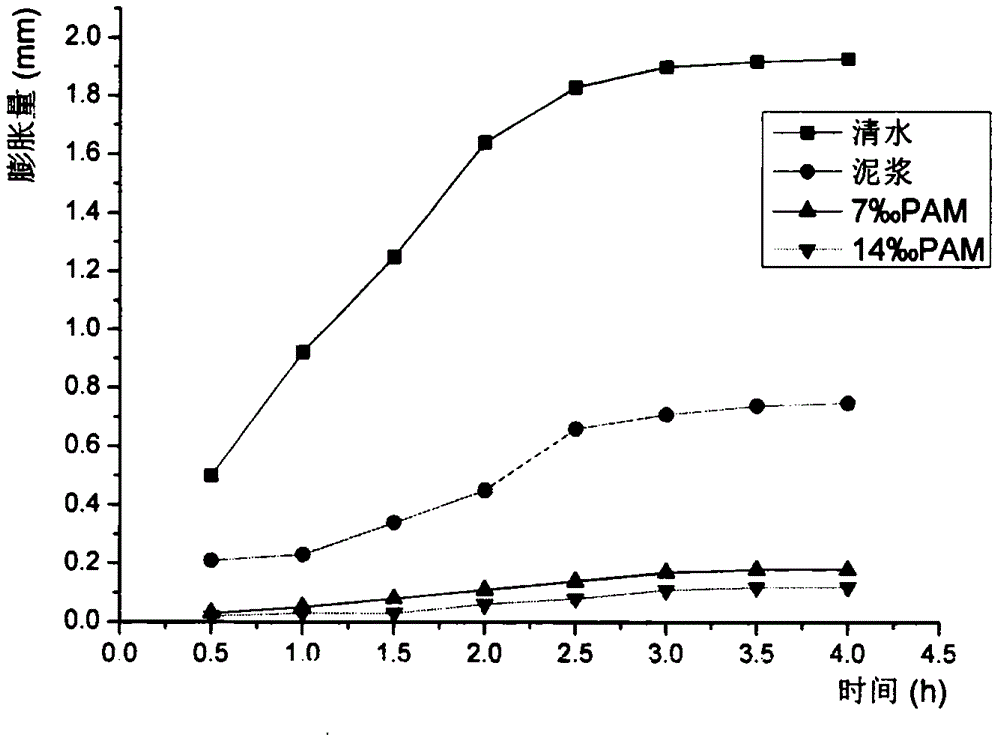

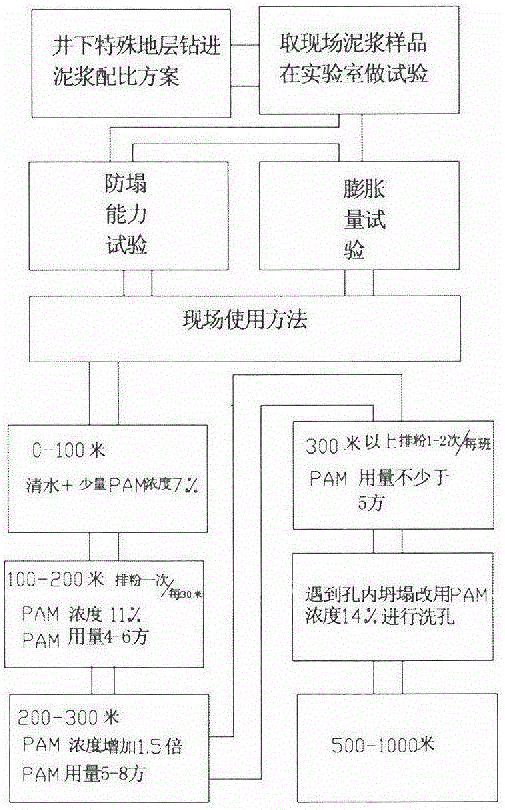

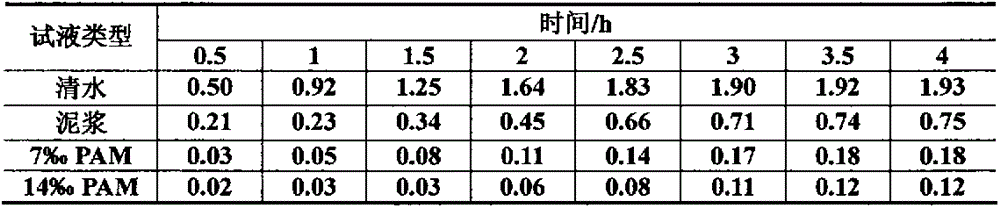

[0036] Depend on figure 1 It can explain in detail the technical plan process of preparing mud for underground drilling into broken and soft formations; one is to analyze the on-site core in the laboratory, complete the experiment of simulating the actual formation conditions in the laboratory, and do the expansion test and anti-slump test; the other is to use The mud prepared in the laboratory is actually drilled by the method used on site to prove the experimental effect, and the mud required for drilling under the geological conditions is satisfied theoretically and experimentally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com