Porous pre-buried channel and machining method thereof

A technology of pre-embedded channel and processing method, which is applied to earth-moving drilling, manufacturing tools, furnace types, etc., can solve the problems of poor equipment stability and insufficient strength of pre-embedded channels, and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

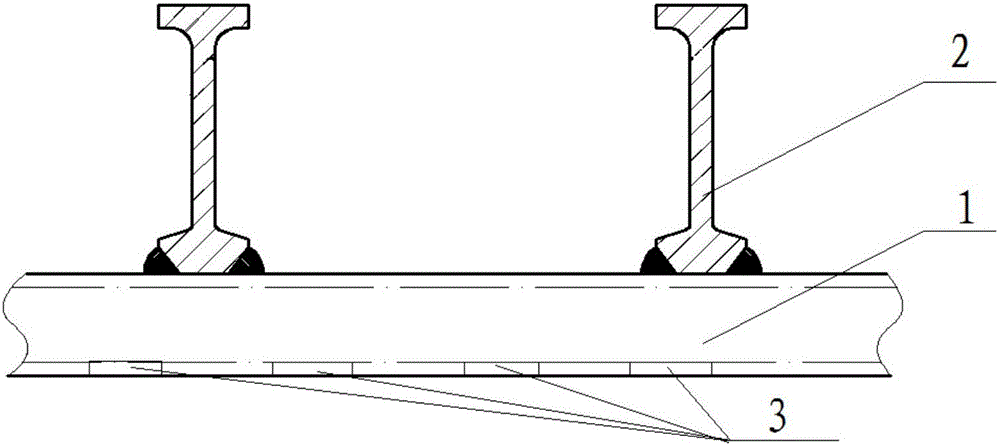

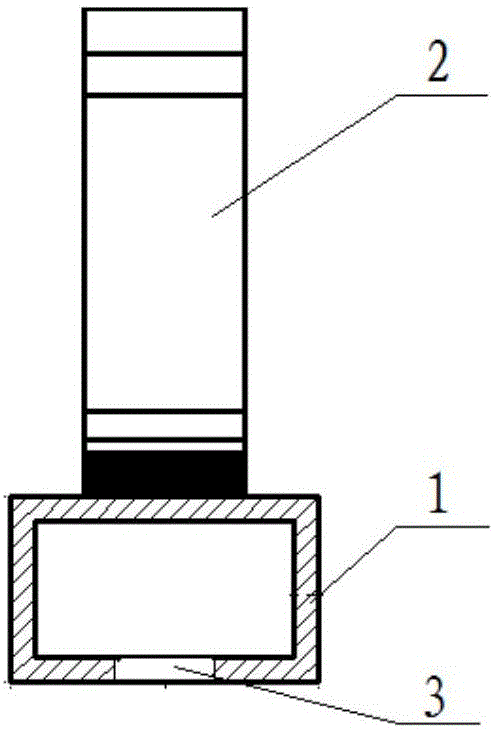

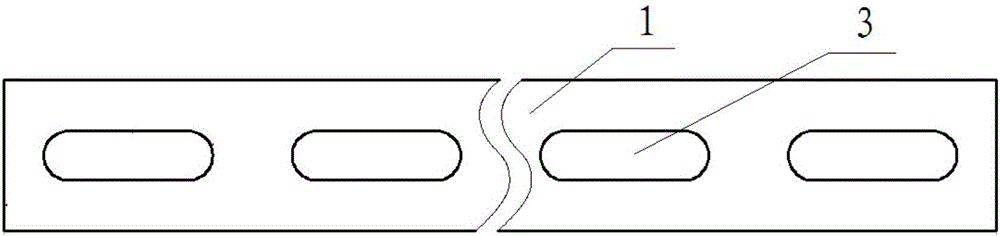

[0043] As mentioned in the background technology section, in order to ensure that the center distance between adjacent bolts can be adjusted, the current embedded channel cannot guarantee sufficient strength of the embedded channel. Slippage can occur, causing the installed equipment to shift or even fall.

[0044] Based on the above research, the embodiment of the present invention provides a porous pre-embedded channel and its processing method. Since a plurality of strip-shaped through holes are set at the bottom of the square tube, it can ensure that the T-bolts are placed in the strip-shaped On the premise that the distance between the centers of adjacent T-bolts can be adjusted, the strength of the pre-embedded channel can be improved through the junction of adjacent strip-shaped through holes, and at the same time, the T-bolts can be axially stressed along the channel. When the force is applied, the installed equipment will not move or fall.

[0045] In order to make t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com