Double-jet-pump structure and jet head

A jet pump and jet head technology, applied to engine components, liquid fuel feeders, machines/engines, etc., can solve the problems of increased parts cost, complex structure, filter area limitation, etc., and achieve compact structure and reduced lateral size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

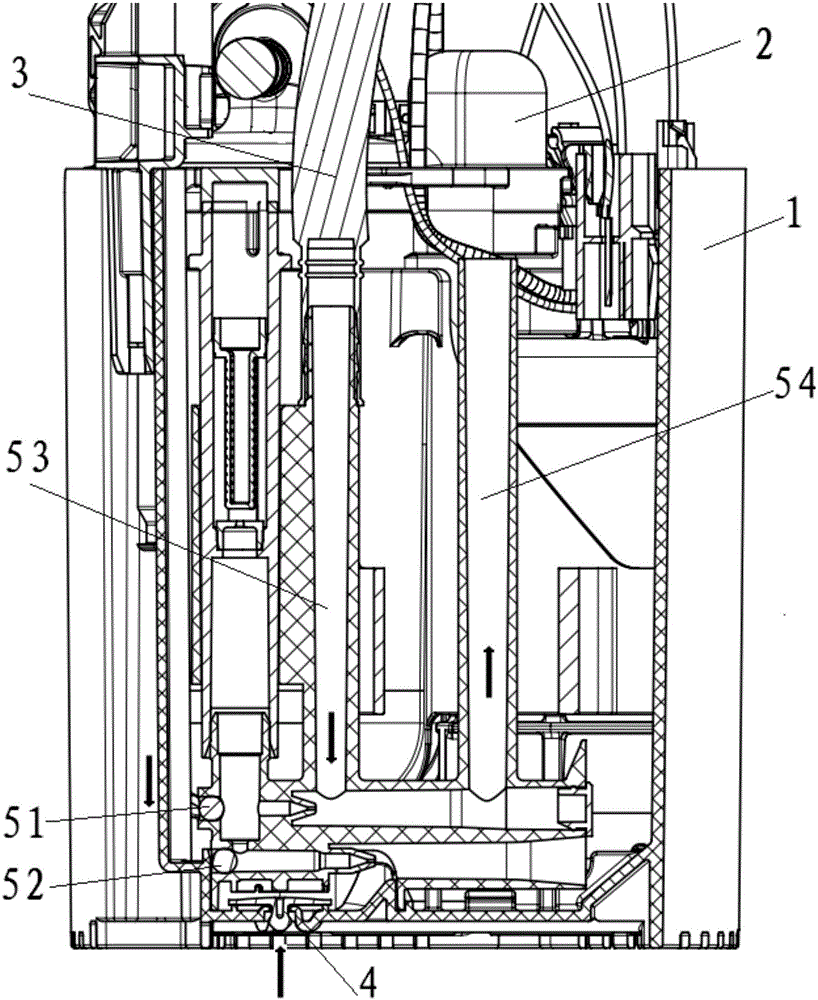

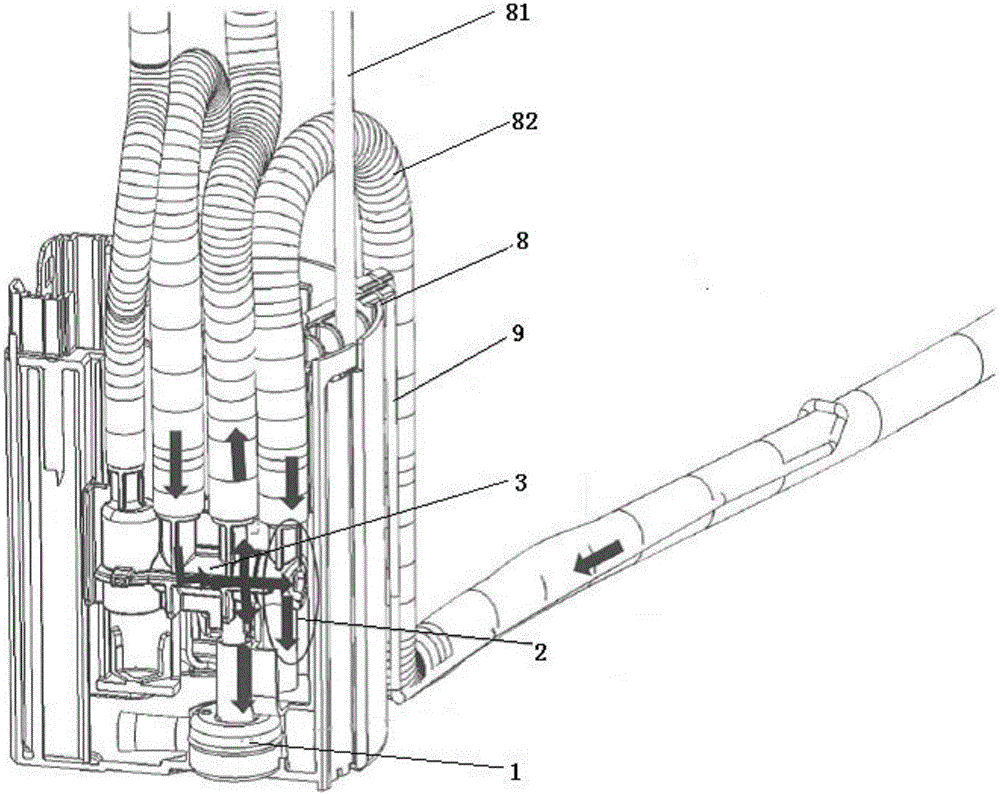

[0083] The double jet pump structure is used to place in the oil barrel, and the oil barrel is placed in the main oil tank; if figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the dual jet pump structure includes a fluid pipe assembly 3, a first jet pump 1, and a second jet pump 2;

[0084] The fluid pipe assembly 3 includes a first pipeline 32, a second pipeline 33, and an oil suction pipe 35;

[0085] The first pipeline 32 is connected to the first injection pump 1;

[0086] The second pipeline 33 is connected to the second injection pump 2;

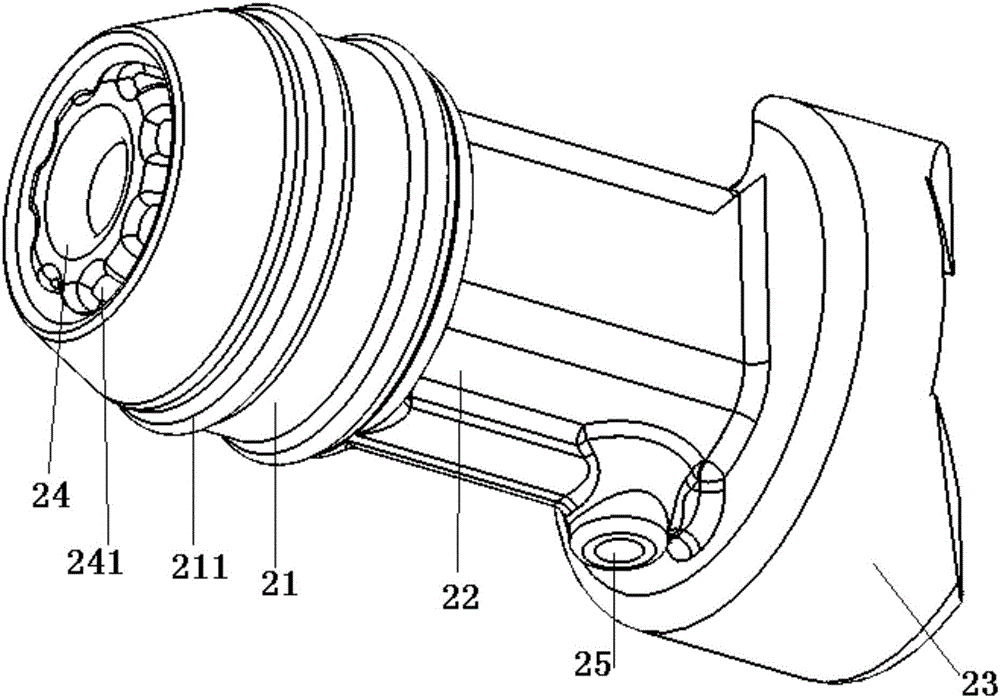

[0087] The second injection pump 2 includes an injection head, and the injection head is a head 21, a body 22, and a tail 23 in sequence along the axial direction;

[0088] The lumens of the head 21 and the body 22 are both tubular and communicated;

[0089] On the outer wall of the body 22, there is a spray hole 25 which communicates with the inner cavity of the body 22 along the radial direction;

[0090] ...

Embodiment 2

[0098] Based on the dual-jet pump structure of Embodiment 1, the fluid pipe assembly 3 further includes a third pipeline 31 and a fourth pipeline 34;

[0099] The third pipeline 31 is used to send oil out of the fuel tank;

[0100] The fourth pipeline 34 is used for the oil pump to supply oil to the fluid pipe assembly 3 .

[0101] Preferably, the axes of the first pipeline 32, the third pipeline 33, the fourth pipeline 34 and the oil suction pipe 35 are longitudinal;

[0102] The axis of the second pipeline 33 is transverse.

[0103] Preferably, the first pipeline 32 , the third pipeline 33 and the fourth pipeline 34 are on the same side of the second pipeline 33 , and the oil suction pipe 35 is on the opposite side of the second pipeline 33 .

[0104] Preferably, the first pipeline 32 faces downward, and the third pipeline 33 and the fourth pipeline 34 face upward.

[0105] In the double jet pump structure of Embodiment 2, the jet head of the second jet pump 2 is arranged...

Embodiment 3

[0107] Based on the dual-jet pump structure of Embodiment 1, such as image 3 , Figure 4 , Figure 5 As shown, the injection head of the second injection pump 2 also includes a filter 24;

[0108] The inner diameter of the nozzle head 21 is greater than the inner diameter of the body 22;

[0109] The filter 24 is cylindrical, and there are one or more grooves 241 on the cylindrical surface of the filter 24 in the axial direction;

[0110] The filter 24 is installed and fixed in the spray head head 21 .

[0111] Preferably, the inner cavity of the nozzle head 21 is cylindrical;

[0112] The filter 24 is cylindrical.

[0113] Preferably, the cross section of each groove 241 in the axial direction of the cylinder of the filter 24 is smaller than the cross section of the injection hole 25 of the second injection pump 2 .

[0114] Preferably, the cylindrical surface of the filter 24 is installed and fixed together with the inner wall of the spray head head 21 through interfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com