A method and system for automatically replenishing Dewar liquid nitrogen on-board a superconducting magnetic levitation vehicle

A Dewar liquid nitrogen and magnetic levitation technology, which is applied to railway vehicles, container filling methods, container discharge methods, etc., can solve time-consuming and labor-intensive problems, and achieve the effects of efficient operation, time saving, and manpower saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

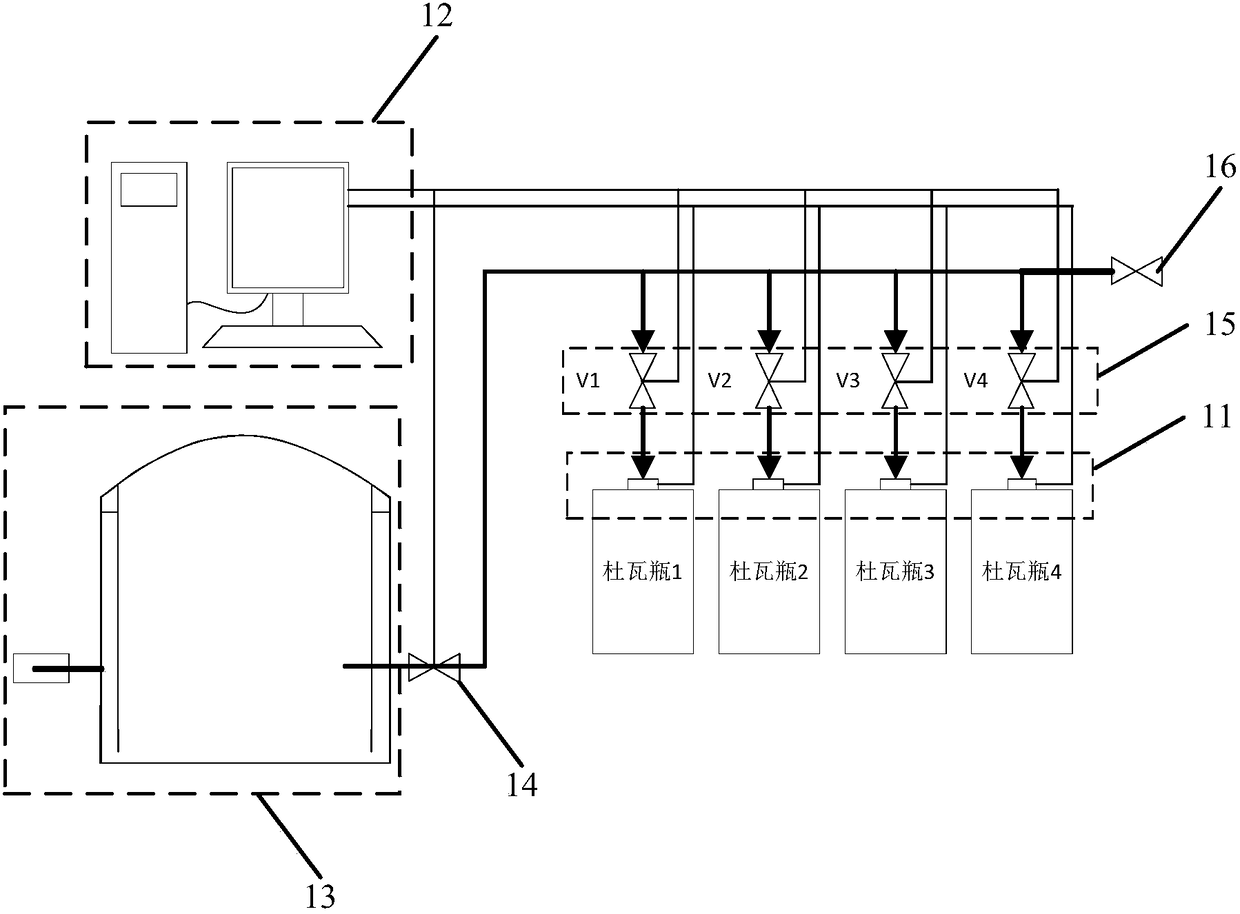

[0057] figure 1 It is a structural schematic diagram of the vehicle-mounted Dewar liquid nitrogen automatic replenishment system for a superconducting maglev vehicle in an embodiment of the present invention. Such as figure 1 As shown, the vehicle-mounted Dewar liquid nitrogen automatic supply system for superconducting maglev vehicles in the embodiment of the present invention mainly includes: at least two sensors 11, a controller 12, a self-pressurized liquid nitrogen storage tank 13, a main solenoid valve 14, multiple A secondary solenoid valve 15 and an exhaust valve 16;

[0058] The sensors 11 are respectively arranged on the top and the bottom of the container filled with liquid nitrogen for measuring temperature;

[0059] The controller 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com