Automatic testing method for mechanical properties of geotechnical engineering instruments

A technology of geotechnical engineering and detection methods, applied in the field of measurement product quality detection, can solve problems such as automatic input of final detection data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

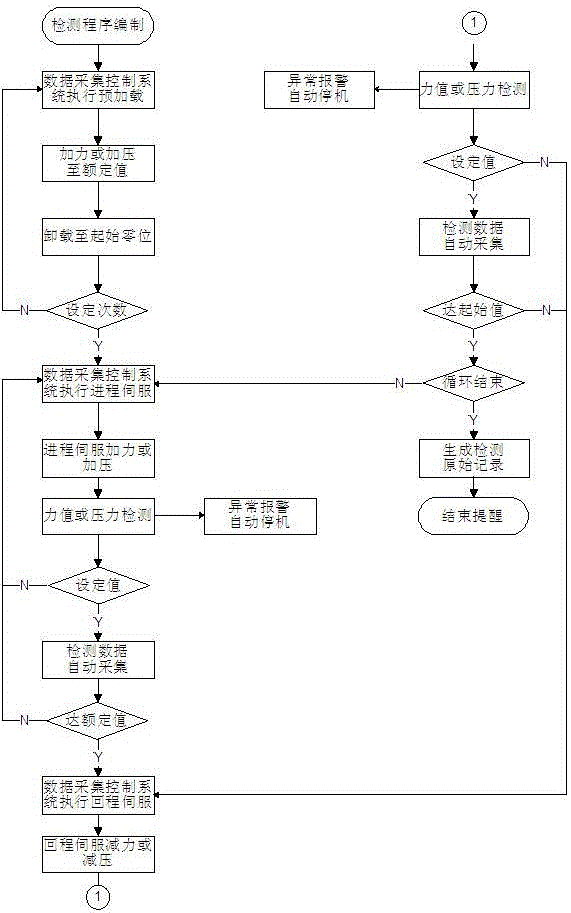

[0028] See attached figure 1 , a brief description of the detection steps as follows:

[0029] Step 1. Automatic preparation of testing procedures: input test parameters (including rated measurement values, preloading times, selection of specific measurement points, loading and unloading speed, arrival measurement Point stability and waiting for measurement data acquisition time, cycle control, etc.), the system automatically compiles the detection program according to the test parameters;

[0030] Step 2. Sample preloading program: After the test starts, the servo booster\pressurization system preloads the test sample with a set number of cycles;

[0031] Step 3. Sample testing procedure: The servo booster\pressurization system performs automatic force value (pressure) control according to the set measurement point of the entry and return stroke and the loading and unloading speed. After reaching the set measurement point and stabilizing, the data acquisition control system ...

Embodiment 2

[0034] The following is a further detailed description of the automatic detection method for the mechanical properties of geotechnical engineering instruments, which is carried out in accordance with the following steps:

[0035] The automatic detection method of mechanical properties of geotechnical engineering instruments is carried out according to the following steps:

[0036] Step 1. According to the input test parameters, the test program including preloading and formal testing is automatically compiled. The specific input test parameters include rated measurement value, preloading times, selection of specific measurement points, loading and unloading speed, and arrival measurement Point stabilization and wait for measurement data acquisition time, loop control, etc.

[0037] Step 2. According to the compiled preloading program, preload the sample according to the set number of cycles:

[0038] 2a. The data acquisition control system calls the preloading program to exec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com