Novel rotation evaporator

A rotary evaporator, a new type of technology, applied in the field of evaporators, can solve the problems of deformation of the cold box, main cooling explosion, parking and other problems, and achieve the effect of reducing the number of layers and reducing the degree of subcooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention are as follows:

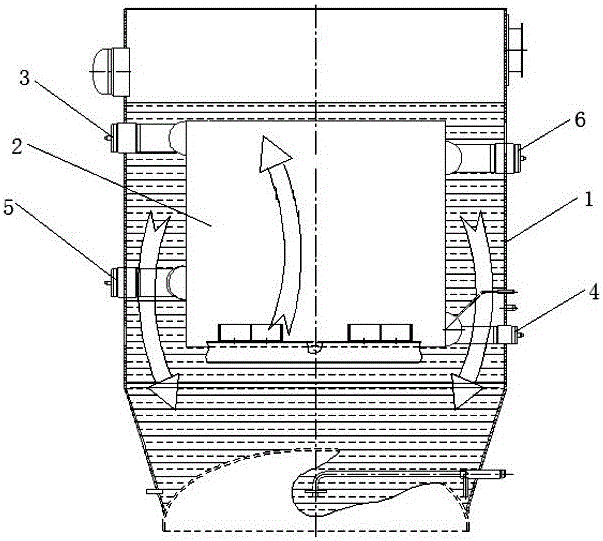

[0011] like figure 1 As shown, the novel rotary evaporator of the present invention includes a housing 1, and the housing 1 is provided with a nitrogen inlet 3, a liquid nitrogen outlet 4, an expansion air inlet 5 and an expansion air outlet 6; There is an expansion air main cold plate 2, and the expansion air main cold plate 2 is respectively provided with a plurality of nitrogen channels, liquid oxygen channels and expansion air channels; the expansion air channels are respectively connected with the expansion air inlet 5 and the expansion air outlet 6 ; The nitrogen channel is connected with the nitrogen inlet 3 and the liquid nitrogen outlet 4 respectively.

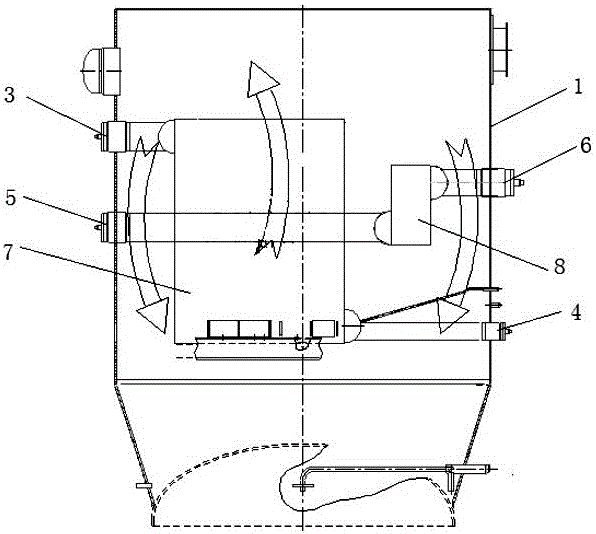

[0012] like figure 2 As shown, another novel rotary evaporator of the present invention includes a housing 1, and the housing 1 is provided with a nitrogen inlet 3, a liquid nitrogen outlet 4, an expansion air inlet 5 and an expansion air outlet 6; the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com