Coil for closed cooling tower heat radiator and manufacturing method of coil

A closed cooling tower and radiator technology, applied in the direction of tubular elements, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of high resource consumption, difficult production of coils, easy freezing and cracking, etc., to increase the condensation area , The effect of convenient production and low market price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

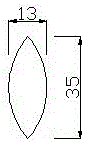

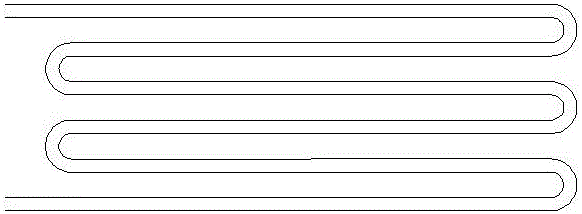

[0019] As attached Figure 1-2 As shown, the coil for a closed cooling tower radiator is characterized by an integrally formed continuous curved pipe structure. The cross-section of the flattened coil is in an olive shape, with a width of 13mm and a height of 35mm. The coil tube uses T2 copper tube, 304, 316 stainless steel or alloy tube and other materials, the diameter of the coil tube is 19mm, and the wall thickness is 0.6mm.

[0020] The manufacturing method of coils for closed cooling tower radiators includes the following steps:

[0021] (1) It is flattened into an olive shape by mechanical clamping, which is relatively straight. The feeding length is determined according to the product specifications, and finally into an olive shape with a width of 13mm and a height of 28mm;

[0022] (2) Continuously bend into one piece from a length of 90 meters by a pipe bender to achieve no joints and no solder joints; figure 2 Shown

[0023] (3) After the coils are bent into pieces, they ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com