Glass fiber linear density intelligent detection device

A glass fiber and intelligent detection technology, applied in the direction of measuring devices, weighing equipment with special properties/forms, instruments, etc., can solve the problems of relying on manual judgment, company loss, misjudgment, etc., and reduce the participation of manual labor , to ensure the working environment, to ensure a clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

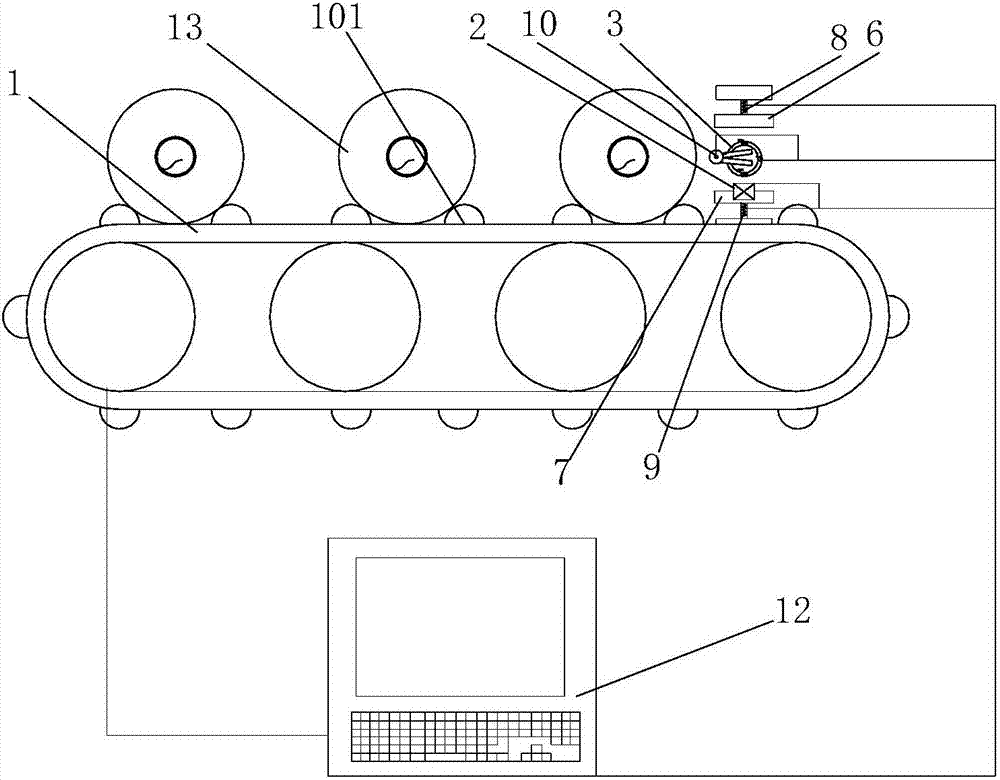

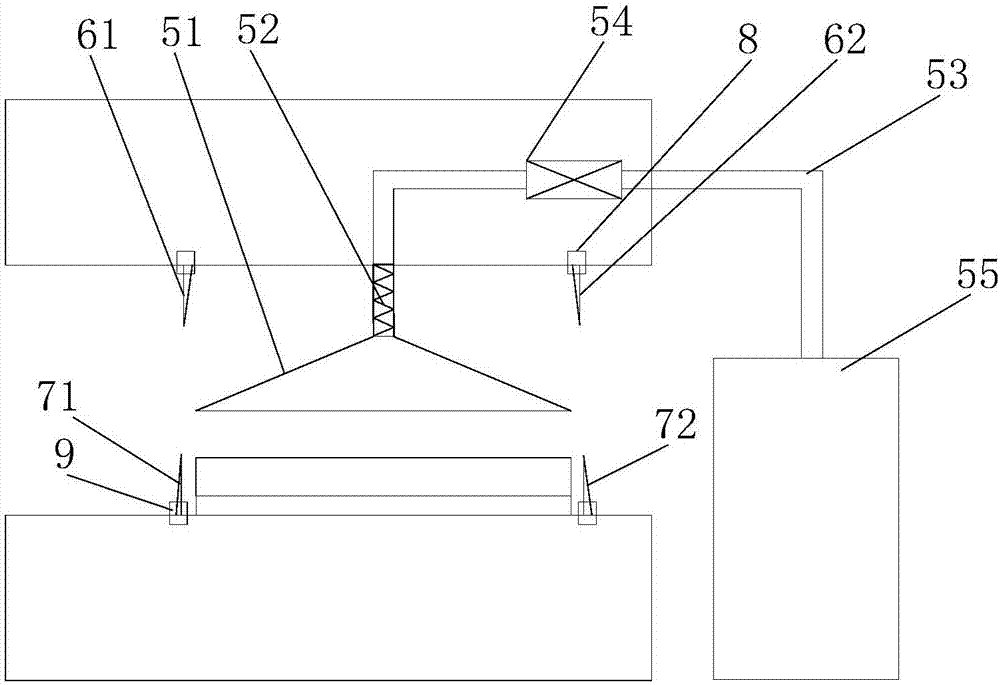

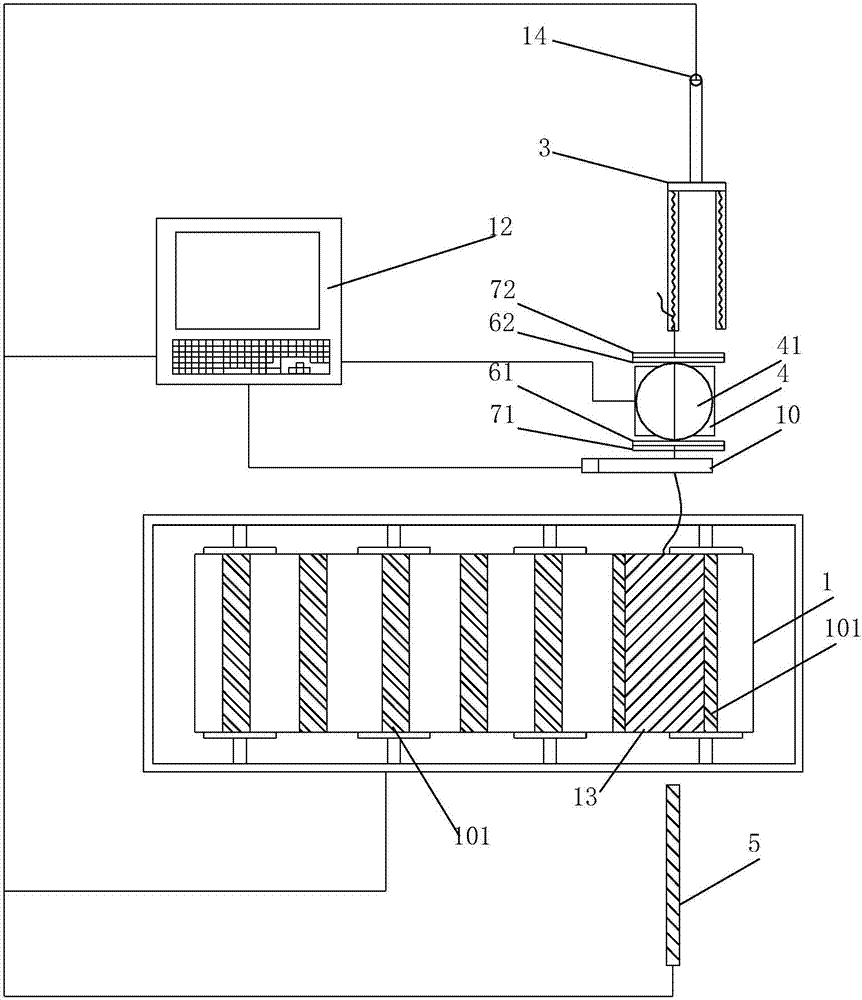

[0022] like figure 1 , figure 2 , image 3 As shown, an intelligent detection device for glass fiber linear density includes a conveyor belt 1, a distance measuring sensor 2, a telescopic thread end clamp 3, an electronic balance 4, a sample recoverer 5, an upper knife group 6, a lower knife group 7, and an upper knife group drive Device 8, lower knife group drive device 9, fixed clip 10, defective product sorter 11, intelligent controller 12 and tension sensor 14.

[0023] The intelligent controller 12 is respectively connected with the conveyor belt 1, the distance measuring sensor 2, the retractable wire end clamp 3, the electronic balance 4, the sample recoverer 5, the upper knife group driving device 8, the lower knife group driving device 9, the fixing clip 10, and the defective product sorting 11 electrical information connection, the surface of the conveyor belt 1 is shaped on a positioning protrusion 101, the positioning protrusion is a semi-cylindrical shape, the ...

Embodiment 2

[0030] A glass fiber linear density intelligent detection device involved in this embodiment has the same main composition and structure as that of Embodiment 1, except that: Image 6 As shown, the positioning protrusion 101 is plate-shaped.

Embodiment 3

[0032] A glass fiber linear density intelligent detection device involved in this embodiment has the same main composition and structure as that of Embodiment 1, except that: Figure 7 As shown, the positioning protrusion 101 is in the shape of a triangular prism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com