Support structure applied to miniaturized reflector

A technology for supporting structures and mirrors, applied in installation, optics, instruments, etc., can solve the problems of deformation of optical components, affecting the imaging quality of the system, and the optical surface shape of optical components cannot reach the theoretical design value, etc., to solve the problem of mirror surface The effect of deformation and avoidance of additional stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

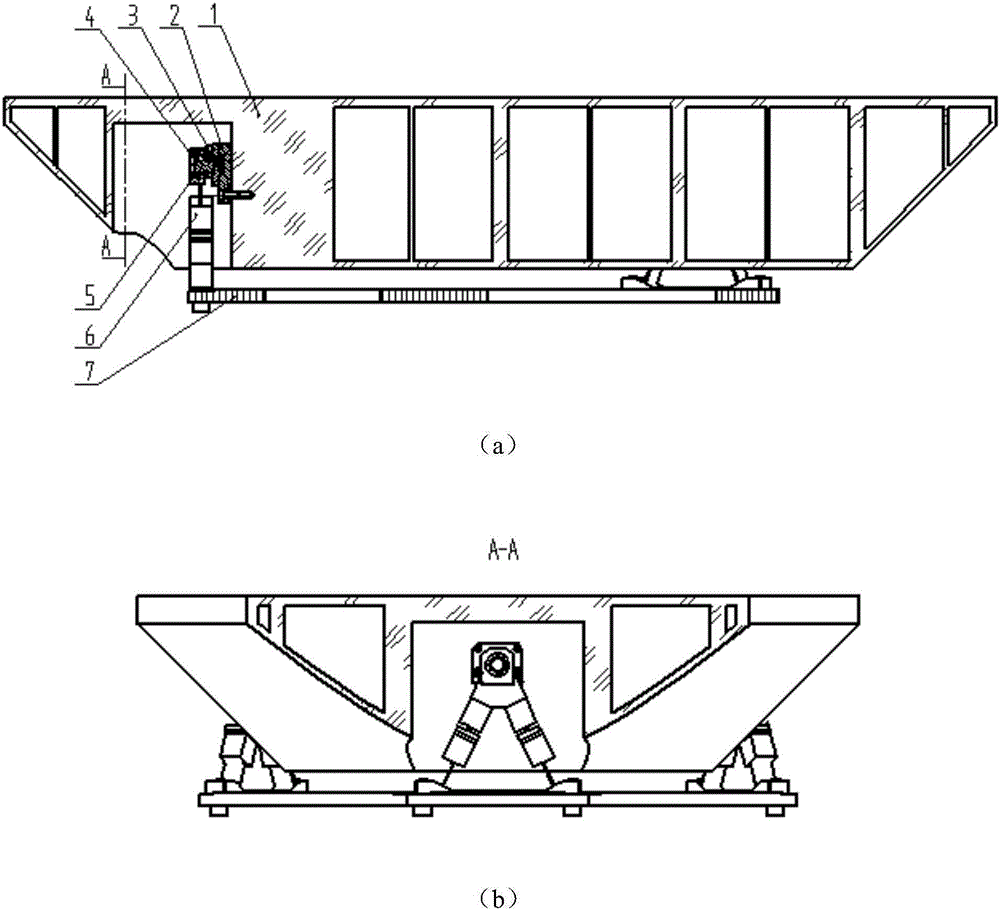

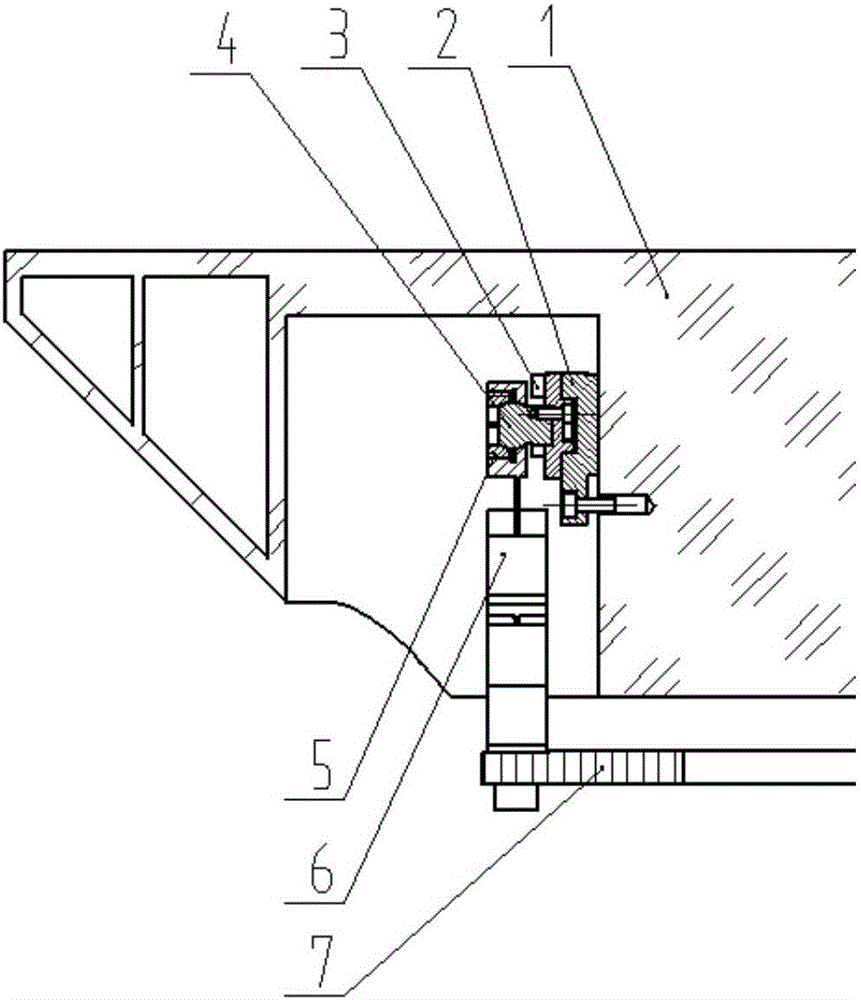

[0016] The present invention is implemented through the following technical solutions. figure 1 It is a structural diagram of the present invention, which includes a reflector 1 with grooves on the back, a bonding block 2, a connecting screw 3, a ball head 4, a conical pressure ring 5, a supporting foot 6 and a connecting plate 7. Adhesion is adopted between the reflector 1 and the three adhesive blocks 2, figure 2 It is an enlarged view of the reflector 1, one of the adhesive blocks and the supporting structure. The reflector 1 and the bonding block 2 are respectively connected to the three support feet 6 through the ball head 4, and the conical pressure ring 5 presses the ball head 4 so that the support foot 6 can rotate flexibly relative to the reflector 1 without gaps. Thereby eliminating the additional stress that occurs when the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com