Large axial chromatic aberration linear dispersion object lens

An axial chromatic aberration and linear technology, applied in the field of optical objective lenses, can solve the problems of unincorporated imaging quality, large objective lens size, and enlarged objective lens size, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0033] Aiming at the existing problems, the present invention provides a linear dispersion objective lens with large axial chromatic aberration. The linear dispersion objective lens can be used for non-contact measurement based on spectral confocal technology. It plays a role in real-time or non-real-time detection of manufacturing.

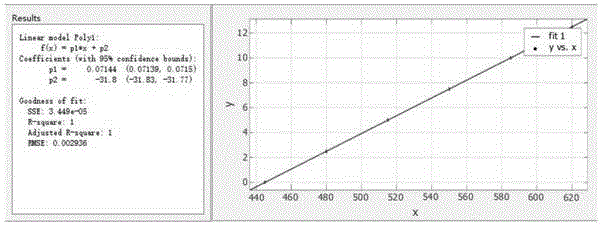

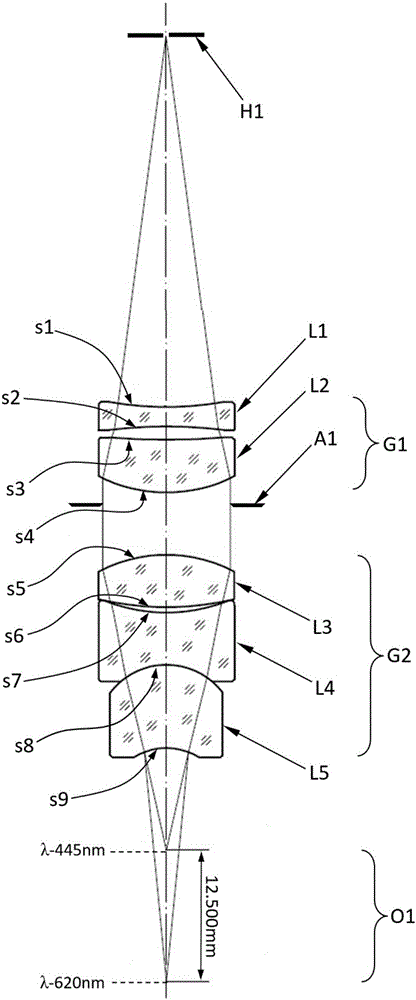

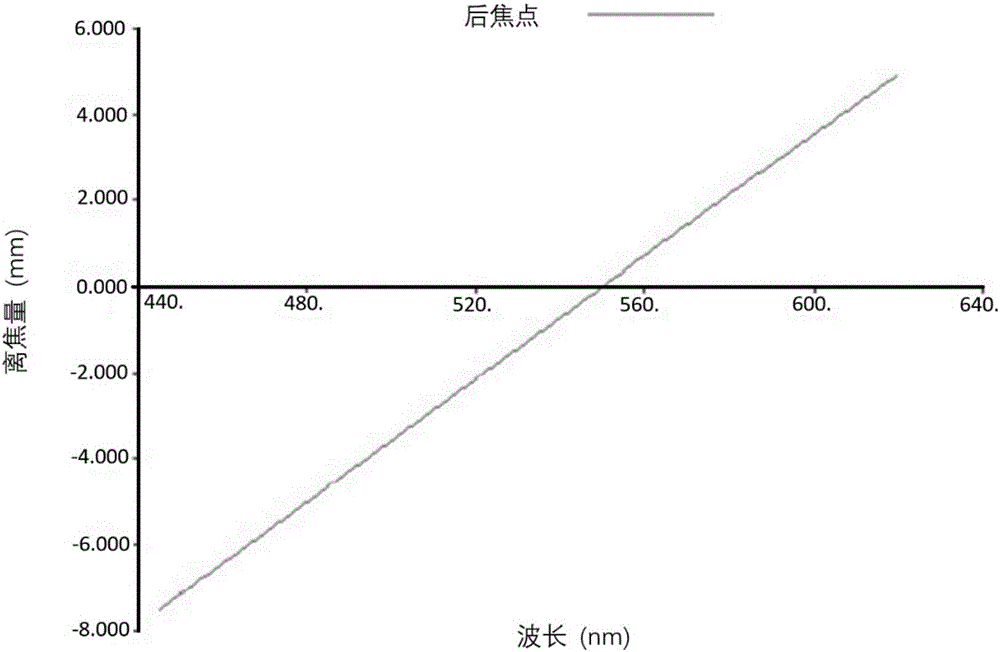

[0034] Such as figure 1 It is an embodiment of the linear dispersion objective lens with large axial chromatic aberration of the present invention.

[0035] The linear dispersion objective lens of the present invention specifically includes a collimating lens group and a focusing lens group, the collimating lens group and the focusing lens group are sequentially arranged along the optical axis between the pinhole of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com