Fuzzy matching and ratio value feedback based cement batching system and method

A technology of fuzzy matching and batching system, applied in general control system, control/adjustment system, instrument, etc., can solve the problems of deviation between raw material rate value and expected rate value, avoid manual experience, improve objectivity and reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

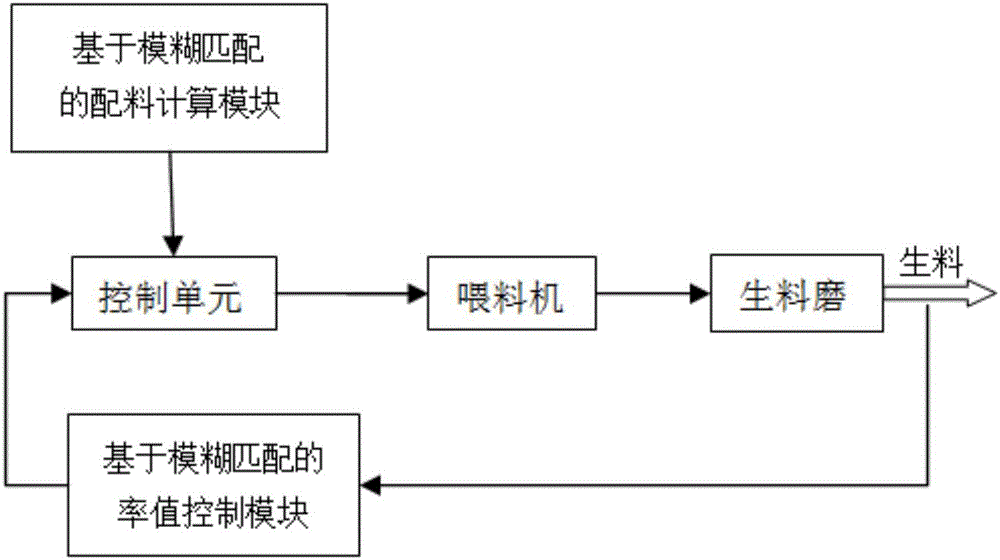

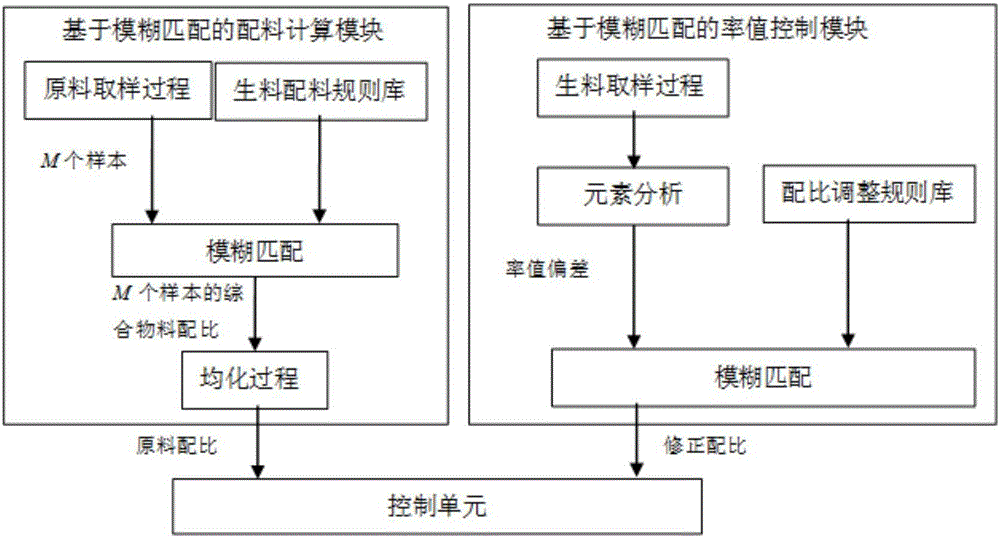

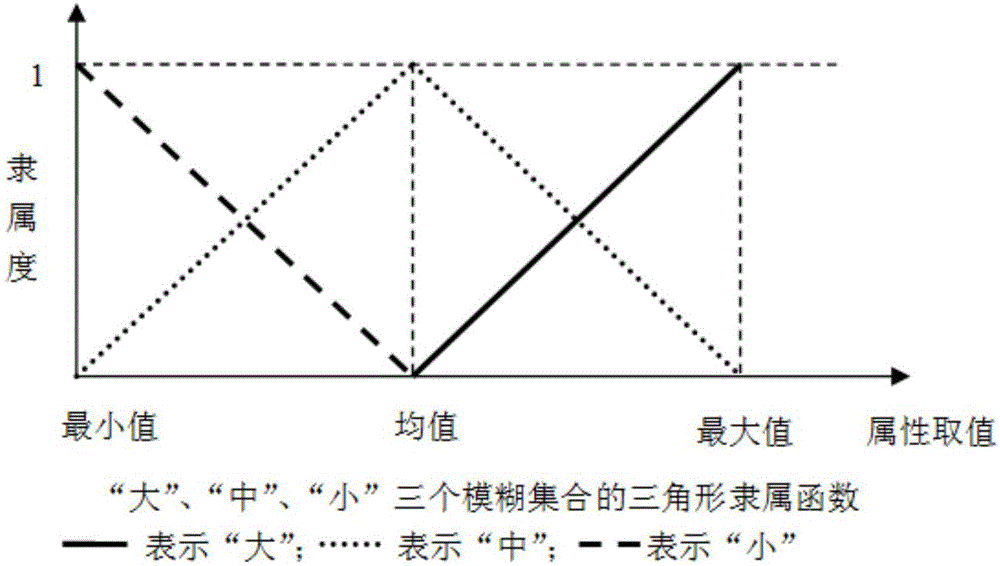

[0018] The invention relates to a cement batching system based on fuzzy matching and rate value feedback, which includes a fuzzy matching based batching calculation module and a fuzzy matching based rate value control module. The ingredient calculation module based on fuzzy matching extracts a number of samples from raw materials in a multi-point sampling manner through the sampling process, detects and determines the chemical components of each sample, and then calculates the chemical composition of each sample by the raw ingredient ingredient rule library according to the multi-rule fuzzy matching method. Comprehensive material ratio, and finally the homogenization process calculates the raw material ratio based on the comprehensive material ratio of all samples. The rate value control module based on fuzzy matching, by sampling the raw meal, the content of various oxides in the raw meal sample is detected by the elemental analyzer, thereby calculating the raw meal rate value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com