Stripping method and stripping device

A stripping device and stripping starting point technology, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of protective tape blockage, high operating cost of stripping tape, and complicated structure, and achieve the effect of suppressing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

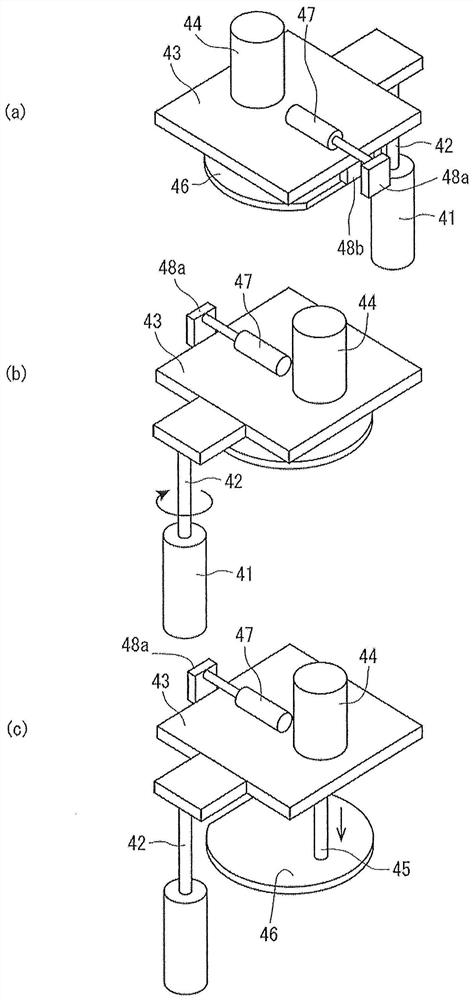

[0036] Hereinafter, preferred embodiments of a peeling method according to the present invention and a peeling device for performing the peeling method will be described in detail with reference to the drawings.

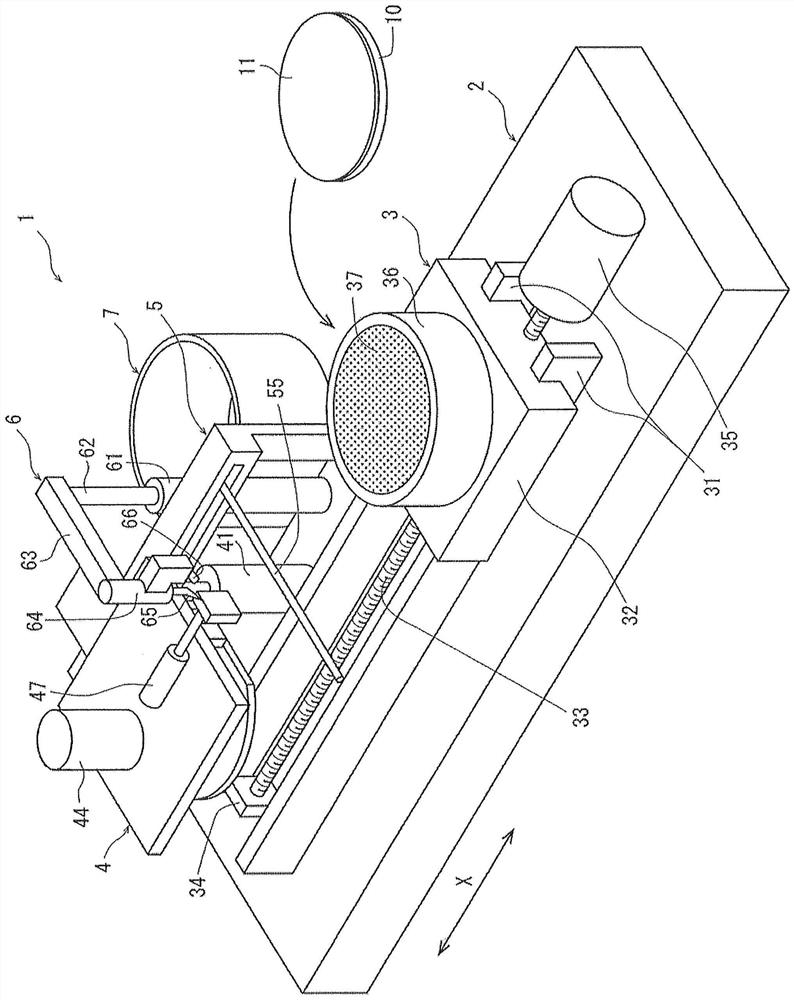

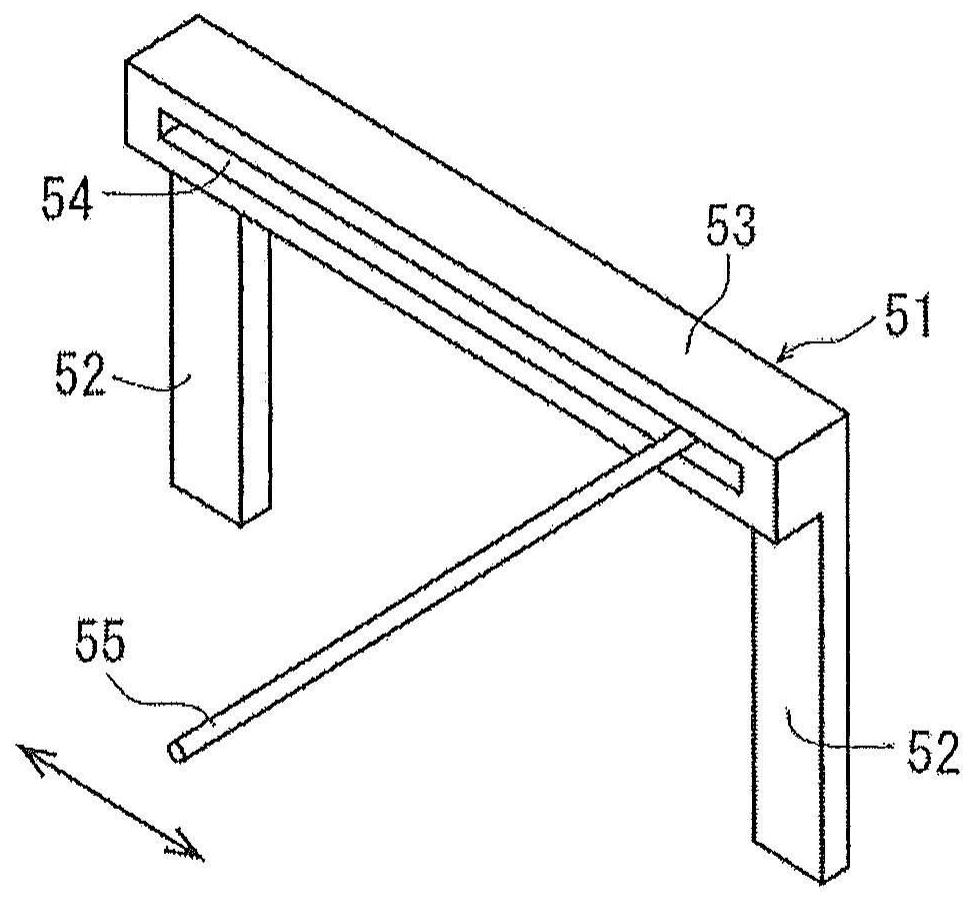

[0037] exist figure 1 A perspective view of an embodiment of a peeling device 1 constructed according to the present invention is shown in . The peeling device 1 in the illustrated embodiment includes a stationary base 2 , a holding table mechanism 3 , a sheet holding unit 4 , a bending roller moving unit 5 , a peeling starting point generating unit 6 , and a waste container 7 .

[0038] As shown in the figure, the holding table mechanism 3 includes: two guide rails 31, 31, which are arranged on the stationary base 2 along the feeding direction (peeling direction) of the peeling process shown by arrow X; 32, which is slidably arranged on the two guide rails 31, 31; the ball screw shaft 33, which is engaged with the nut portion on the lower surface of the mobile base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com