A kind of photovoltaic photodetector based on tapered metasurface structure and its preparation method

A photodetector and metasurface technology, applied in the field of photodetectors, can solve problems such as angle sensitivity and complex preparation process, and achieve the effect of high-efficiency photodetection and wide-angle photodetection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

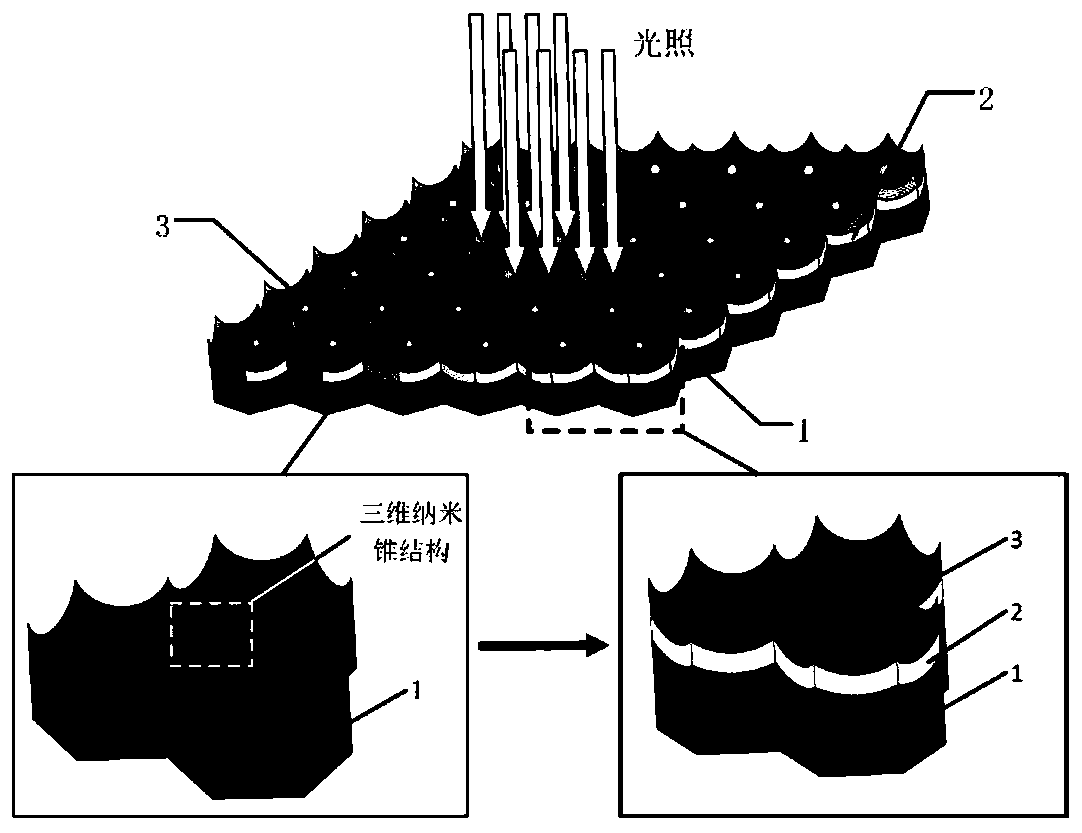

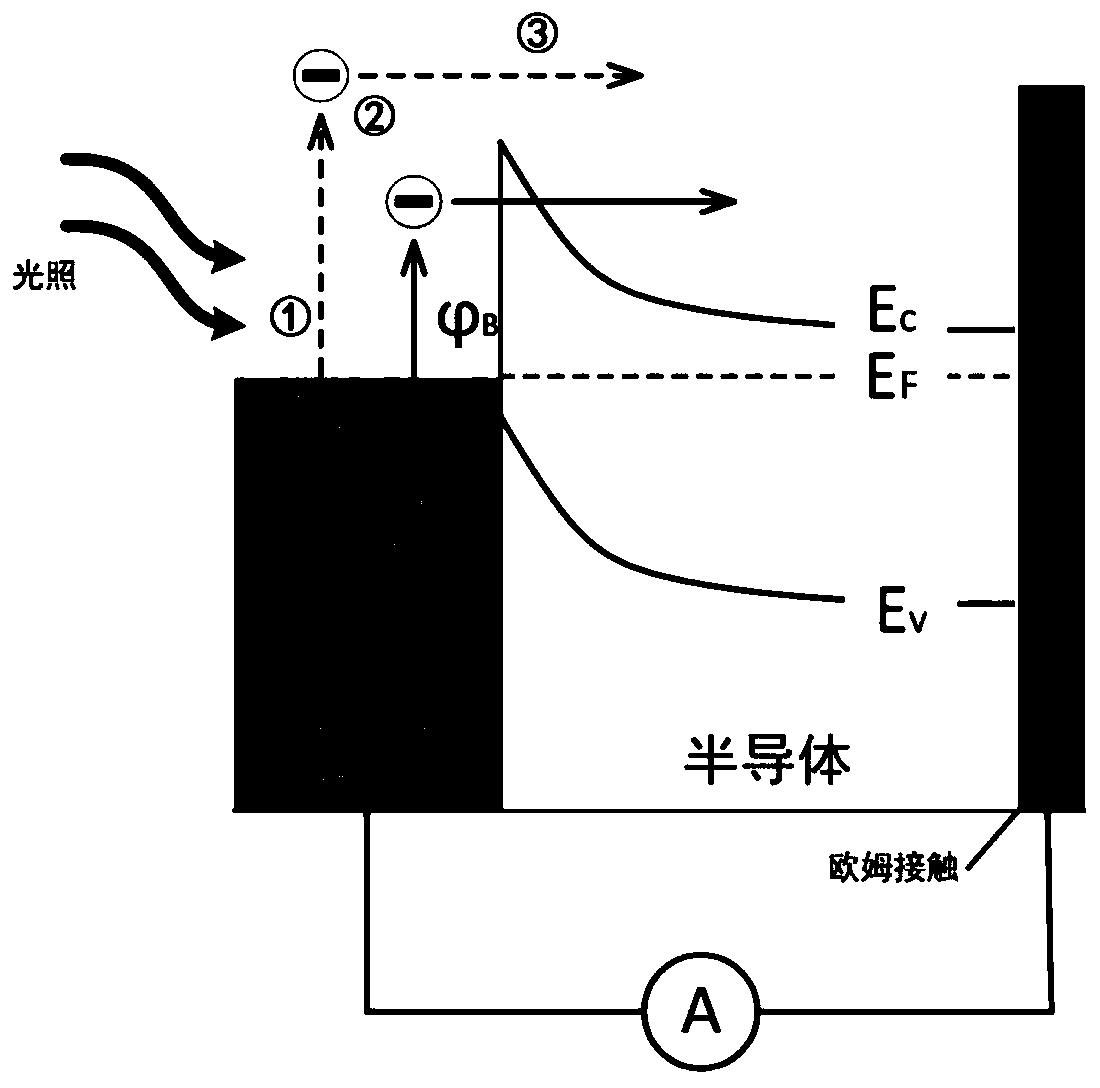

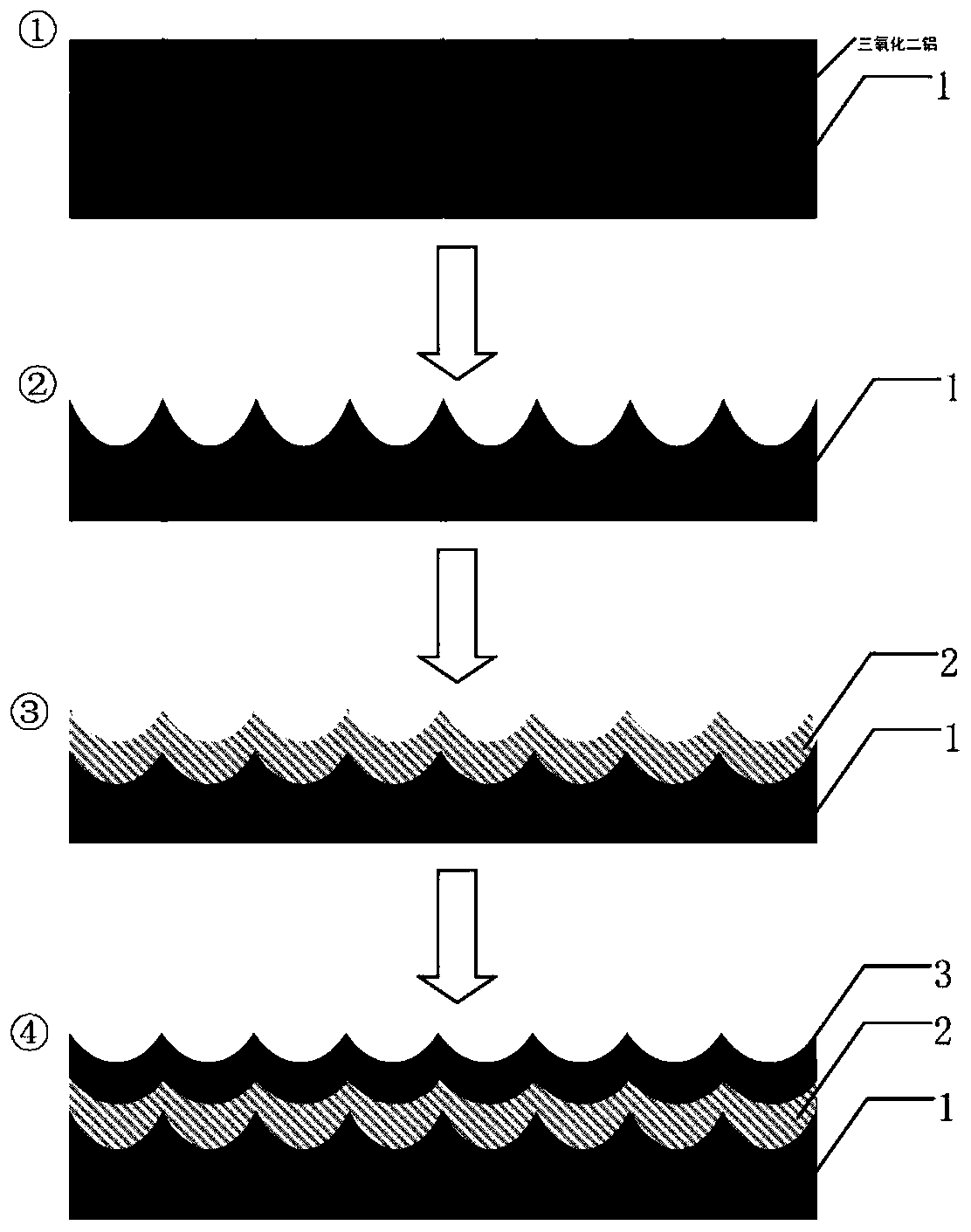

[0039] In order to realize a photodetector suitable for a wide spectrum and wide angle in the visible light region, the photodetector based on the tapered metasurface structure in this embodiment includes an aluminum substrate with a three-dimensional nanocone array structure on the surface, a titanium dioxide semiconductor layer, and a gold film layer . Wherein the gold thin film layer has a thickness of 20nm, and the titanium dioxide semiconductor layer has a thickness of 40nm. The nano cone array is a non-periodic array, the height of the nano cones is between 100-500nm, and the distance between the nano cones is kept between 100-500nm.

[0040] When the full band of visible light is incident on the cone-shaped upper surface of the detector, the conical metasurface structure is different from the common use of plasmon resonance modes or resonant cavities that can only achieve superabsorption at a single wavelength or a single incident angle. The metasurface structure, the wi...

Embodiment 2

[0048] In order to realize a photodetector suitable for a wide spectrum and wide angle in the near-infrared region, different from Embodiment 1, the semiconductor thin film layer of this embodiment is a silicon thin film, and the specific structural parameters are that the thickness of the gold thin film layer is 15nm, and the thickness of the silicon thin film is 15nm. The thickness of the layer is 50 nm. The nanocone array is a non-periodic array, the height of the nanocones is between 500-1000nm, and the distance between the nanocones is kept between 1000-2000nm. When the surface of the incident photodetector in the infrared region, because the conical metasurface structure is different from the metasurface structure that uses ordinary plasmon resonance modes or resonant cavities can only achieve superabsorption at a single wavelength or a single incident angle, this The wide-band and wide-angle superabsorption that can be realized by this kind of tapered structure.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com