Wiring-free rigid-flex board assembly with four rectangular connectors

A rectangular connector and rigid-flex board technology, applied in the field of avionics, can solve the problems of difficult lead-in technology, difficult post-maintenance, and high randomness, so as to reduce the probability of human error, improve product maintainability, and reduce product weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail,

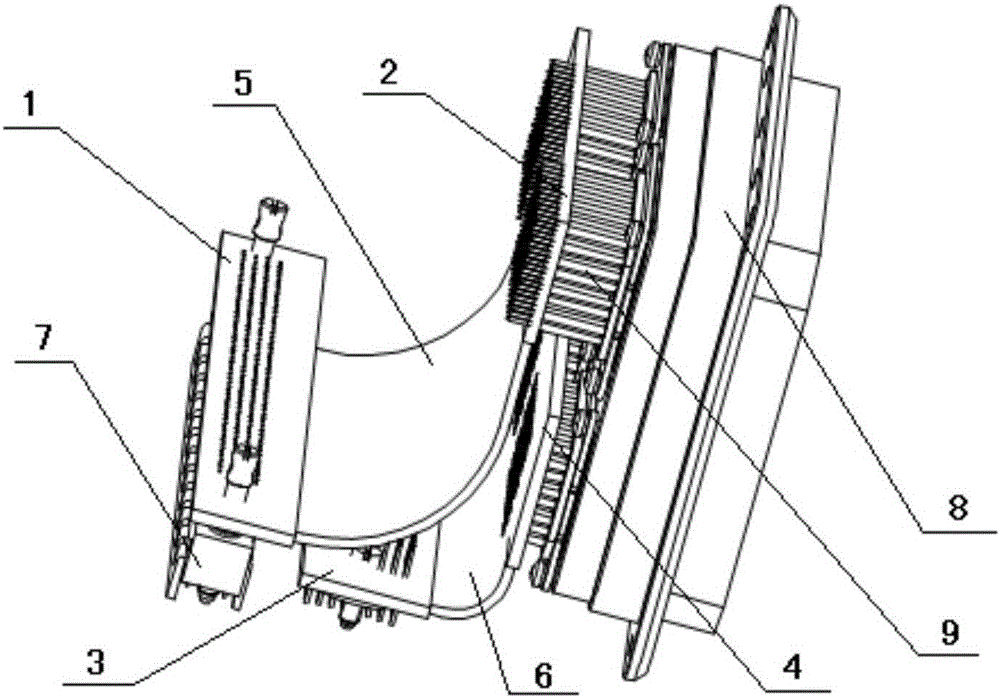

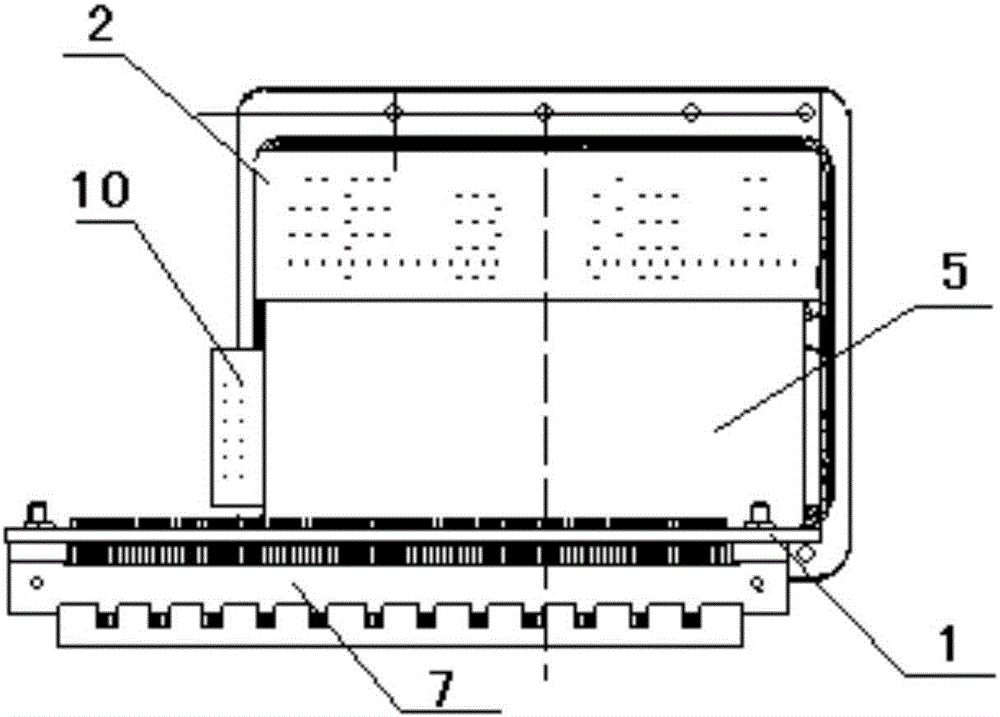

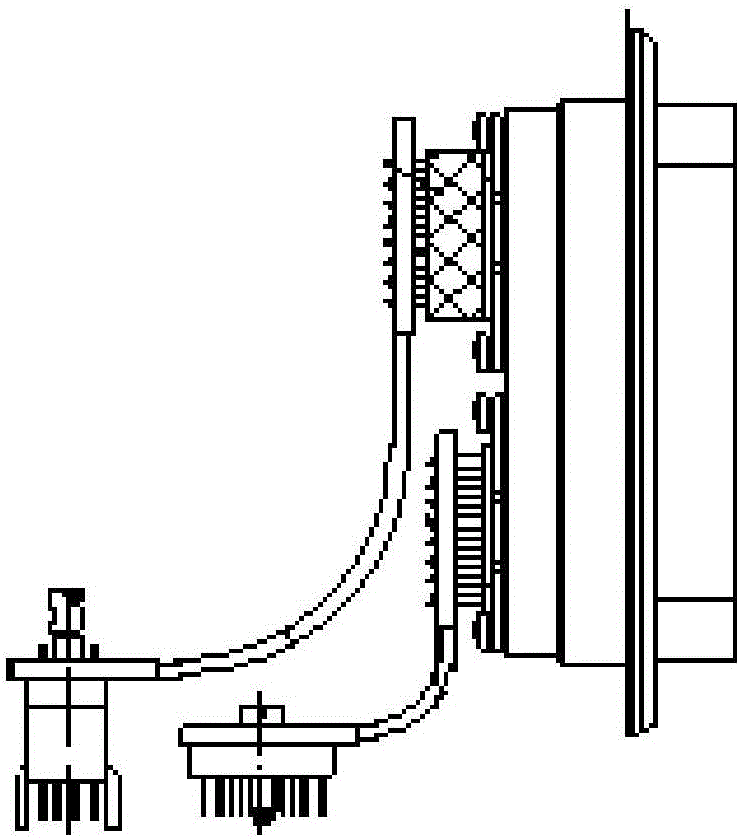

[0016] Rigid-flex wiring-free assembly with four-rectangular connectors realizes wiring-free design of avionics products equipped with four-rectangular connectors:

[0017] The first rigid plate 1 and the second rigid plate 2 are respectively connected to the two ends of the first flexible plate 5, the third rigid plate 3 and the fourth rigid plate 4 are respectively connected to the two ends of the second flexible plate 6, and the first flexible plate 5 and the second flexible board 6 are distributed with printed circuits connecting the signals at both ends, and are stacked and distributed; the first PCB connector 7 and the second PCB connector 13 are installed on the first rigid board 1 and the third rigid board 1 and the third respectively. on the rigid board 3, and can be connected with the motherboard 11 in the chassis 12; the second rigid board 2 and the fourth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com