Cosmetic treatment of keratin fibres

A keratin fiber and fiber technology, applied in the field of keratin fiber, can solve the problems of expensive, not obvious effect, long execution time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 8

[0715] Examples 1 to 8: Compositions with a melting point between 40°C and 120°C

Embodiment 1

[0716] Example 1: Assembly comprising a thermoplastic polymer-based composition and a device with a heating element

[0717] 1) Cosmetic composition

[0718] Compositions according to the invention are prepared as described below.

[0719] All starting materials were weighed out using a balance (accuracy 0.01 g). Compounds were melted in a jacketed 500ml heating plate with hot oil circulation for temperature control. Heat the assembly to about 95°C to 98°C.

[0720] Once the mixture is melted, it is homogenized by stirring using a Moritz mixer (rotor-stator type of stirring consisting of a stationary part where a second moving part rotates at a variable speed) in order to disperse the pigment.

[0721] The composition is then deposited on the mold either in liquid form or in solid form at ambient temperature using heat.

[0722] Formulations were prepared using the following weight ratios.

[0723]

[0724] 2) device

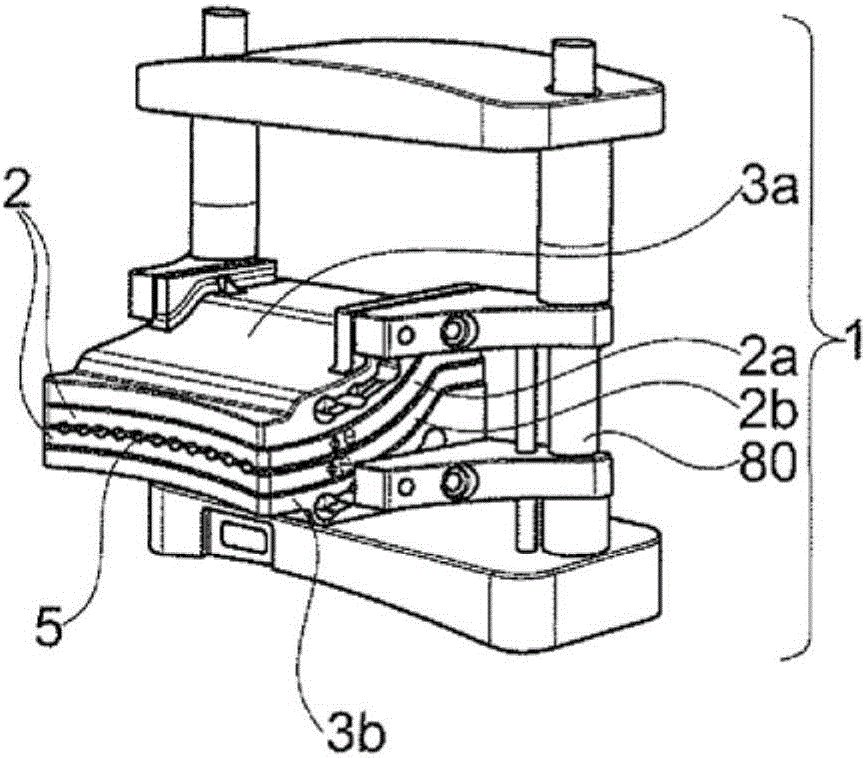

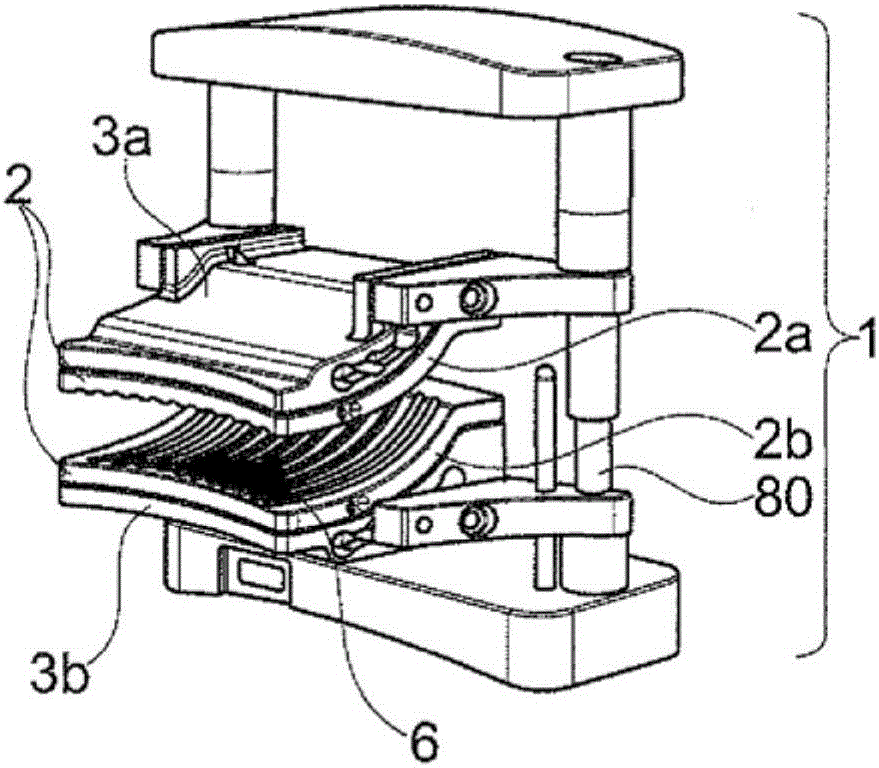

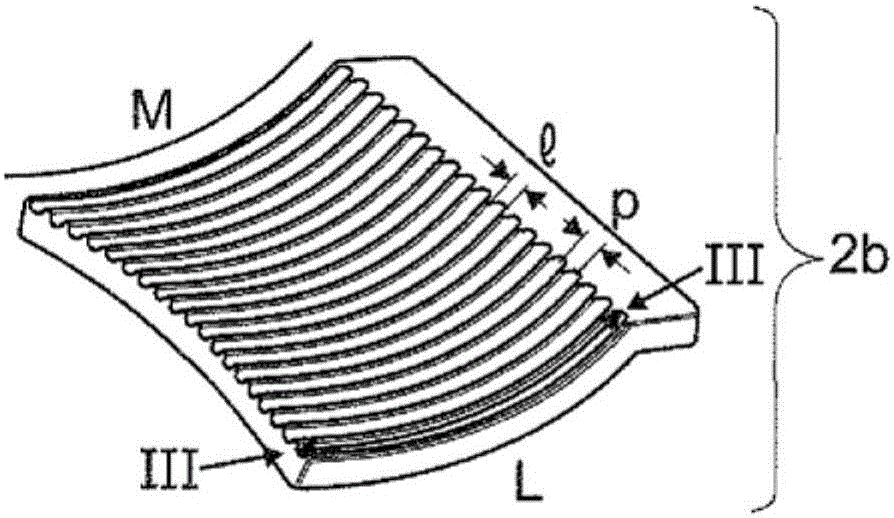

[0725] The device used in Example 1 is as ...

Embodiment 2

[0740] Example 2: Assembly comprising a wax-based composition and a device with a heating element

[0741] 1) Cosmetic composition

[0742] Compositions according to the invention are prepared as described below.

[0743] All starting materials were weighed out using a balance (accuracy 0.01 g). Compounds were melted in a jacketed 500ml heating plate with hot oil circulation for temperature control. Heat the assembly to about 95°C to 98°C.

[0744] Once the mixture is melted, it is homogenized by stirring using a Moritz mixer (rotor-stator type of stirring consisting of a stationary part where a second moving part rotates at a variable speed) in order to disperse the pigment.

[0745] The composition is then deposited on the mold either in liquid form or in solid form at ambient temperature using heat.

[0746] Formulations were prepared using the following weight ratios.

[0747]

[0748] 2) device

[0749] The device used is the same as that of Example 1.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com