Method for producing camshaft assembly

一种凸轮轴、凸轮元件的技术,应用在凸轮、联轴器、发动机元件等方向,能够解决低精度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

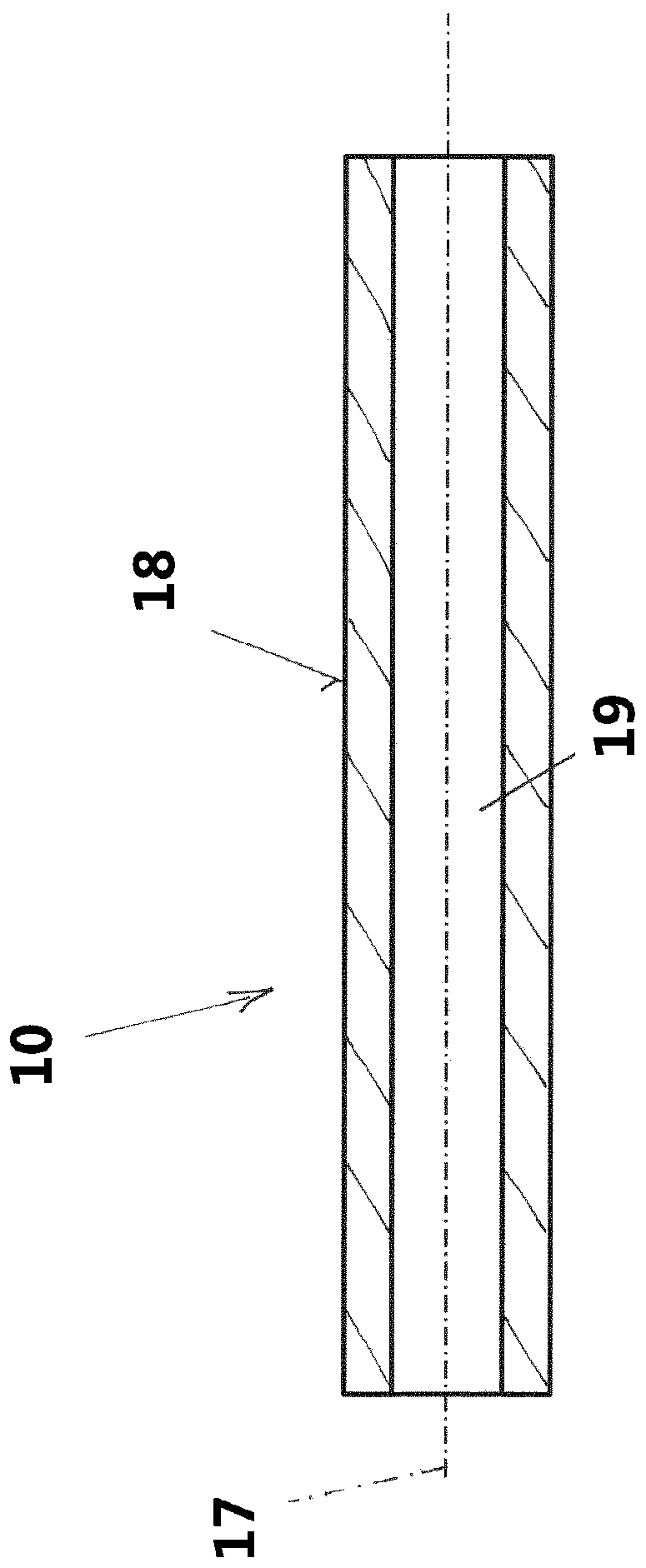

[0031] figure 1Exemplarily shown is a carrier shaft 10 with a non-grinding surface 18 , wherein the carrier shaft 10 is in the form of a hollow shaft and comprises a cavity 19 extending along a central axis 17 . The carrier shaft 10 thus forms a weight-minimized tube extending rotationally symmetrically with respect to the central axis 17 and the carrier shaft 10 can be cut to length, for example, from a rod of material.

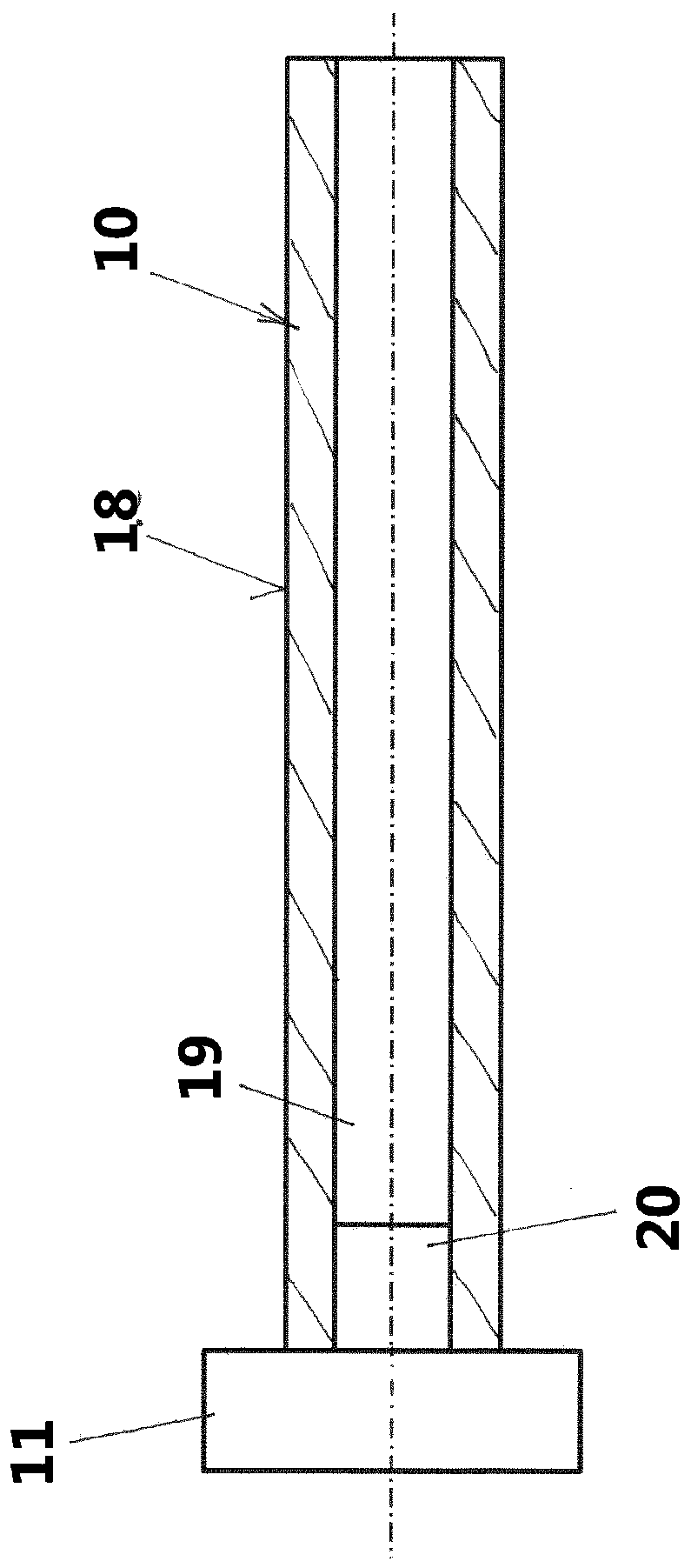

[0032] figure 2 An assembly consisting of a carrier shaft 10 and an end piece 11 is shown, and the end piece 11 may for example be a drive wheel, a phase adjuster or part of a phase adjuster, and in the context of the present invention the end piece 11 is Have part of the camshaft ready for use. For fastening the end part 11, the end part 11 comprises a protrusion 20, which can be inserted, for example, into the cavity 19 of the carrier shaft 10, wherein the end part 11 can also be connected in some other way, for example by an adhesive bonding process. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com