Method for temporary mooring point and cable rope fixing point

A cable wind rope and fixed point technology, which is applied in the field of large-scale equipment assembly, can solve the problems of high construction cost and period, and no suitable fixed point for safety cables, and achieve high utilization efficiency, low construction period and use cost, and rapid deployment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

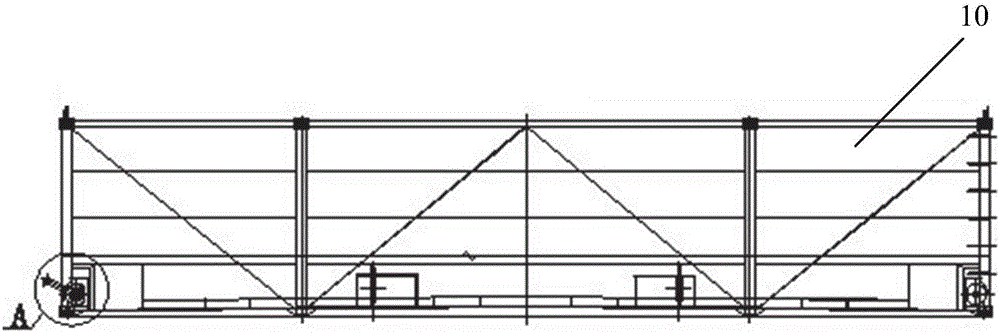

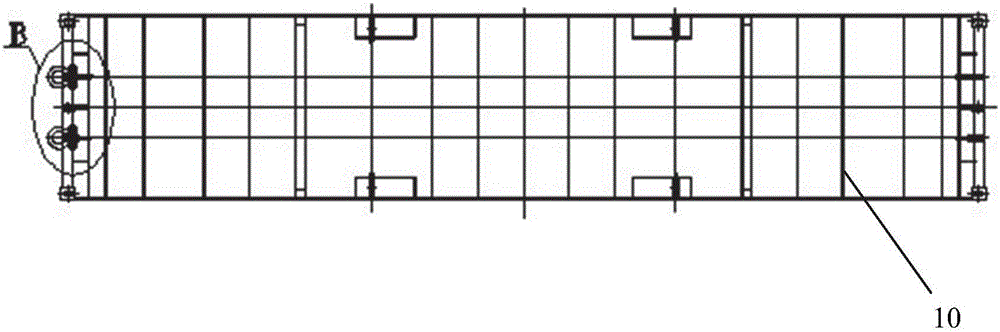

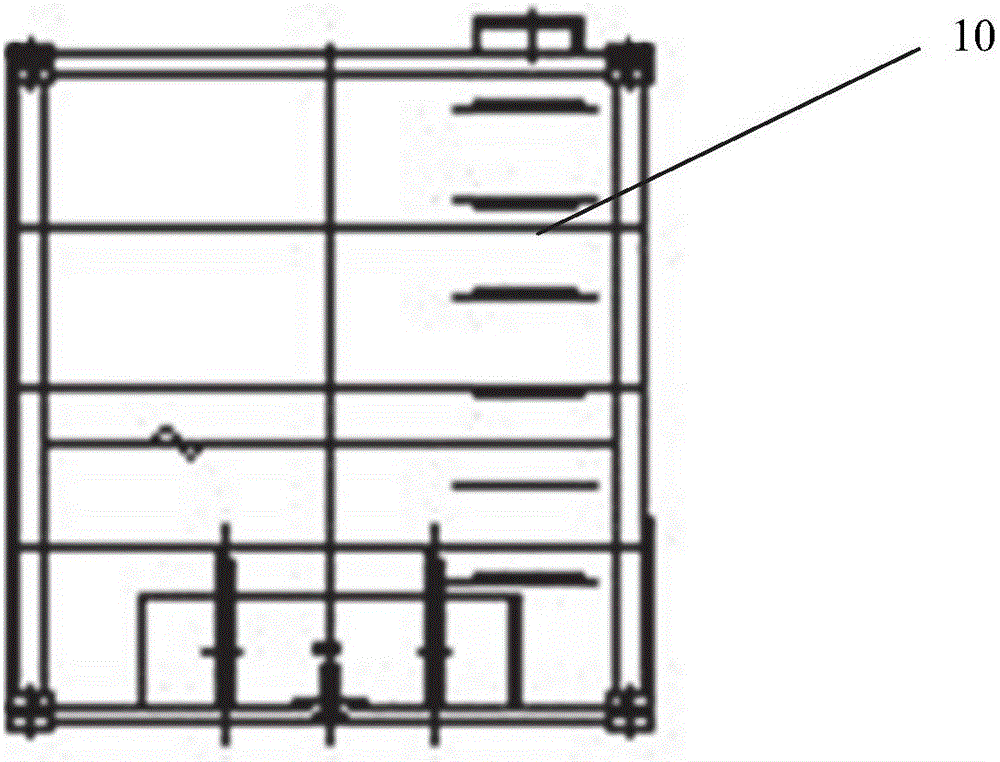

[0033] figure 1 Front view of a water tank for a 40 foot ground anchor in the method of the present invention for temporary mooring points and cable wind rope fixing points. figure 2 Top view of the water tank for the 40 foot ground anchor in the method of the present invention for temporary mooring points and wind rope anchorage points. image 3 Side view of the water tank for the 40 foot ground anchor in the method of the present invention for temporary mooring points and windline anchorage points. Figure 4 for figure 1 Enlarged view of part A in Fig. Figure 5 for figure 2 Enlarged view of part B in . Figure 6 It is a schematic diagram of the water tank combination of two 40-foot ground anchors in the method of temporary mooring point and cable wind rope fixing point of the present invention.

[0034] Such as Figure 1 to Figure 6 As shown, the present invention discloses a method for a temporary mooring point and a fixed point of a cable wind rope, which includes...

Embodiment 2

[0043] Figure 7 Front view of a 20 foot trial weighted water tank for the temporary mooring point and wind rope anchorage point method of the present invention. Figure 8 Top view of a 20 foot trial weighted water tank for the method of the present invention for temporary mooring points and wind rope anchorage points. Figure 9 Side view of a 20 foot trial weight tank for the temporary mooring point and windline anchorage point method of the present invention. Figure 10 It is the combination schematic diagram of the water tank of the ground anchor of 40 feet and the water tank of 20 feet of test weight in the method for temporary mooring point and cable wind rope fixed point of the present invention.

[0044] Such as Figure 7 to Figure 10 shown, combined with Figure 1 to Figure 5 , the invention discloses a method for a temporary mooring point and a fixed point of a cable wind rope, which comprises the following steps:

[0045] Step 1. The water tanks using multiple gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com