A bag opening and closing mechanism on a new bagging machine

A bagging machine and bagging technology are applied in the fields of plant protection cover, horticulture, botanical equipment and methods, etc., which can solve the problem of unreasonable design of the bagging and opening and closing mechanism, affecting fruit yield and bagging efficiency, and unable to meet the requirements of orchard cover. Bag requirements and other issues, to achieve the scientific simplification of bagging and sealing procedures, convenient interspersed positioning, compact and concise structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

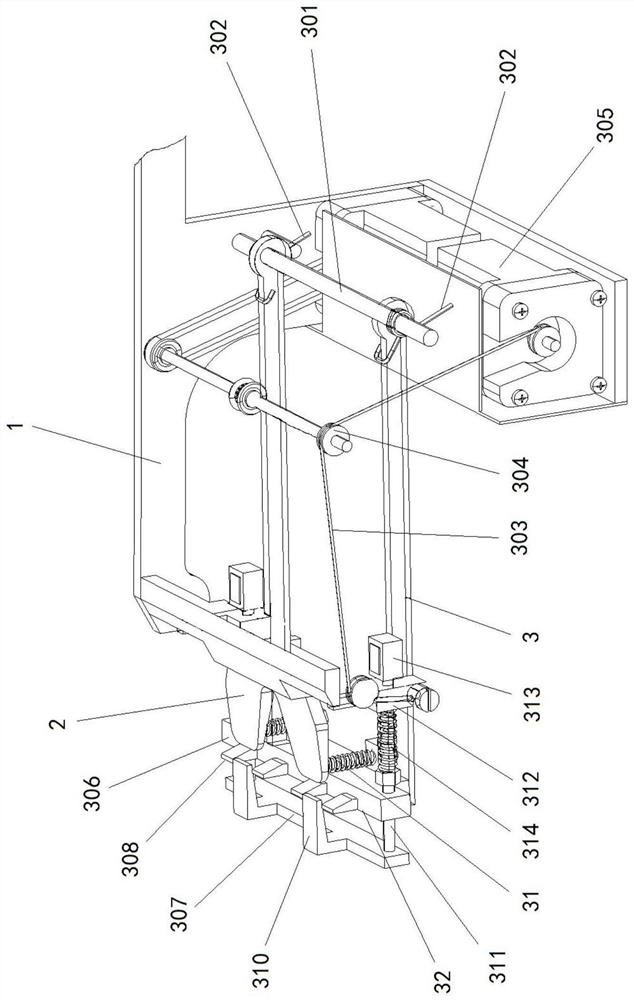

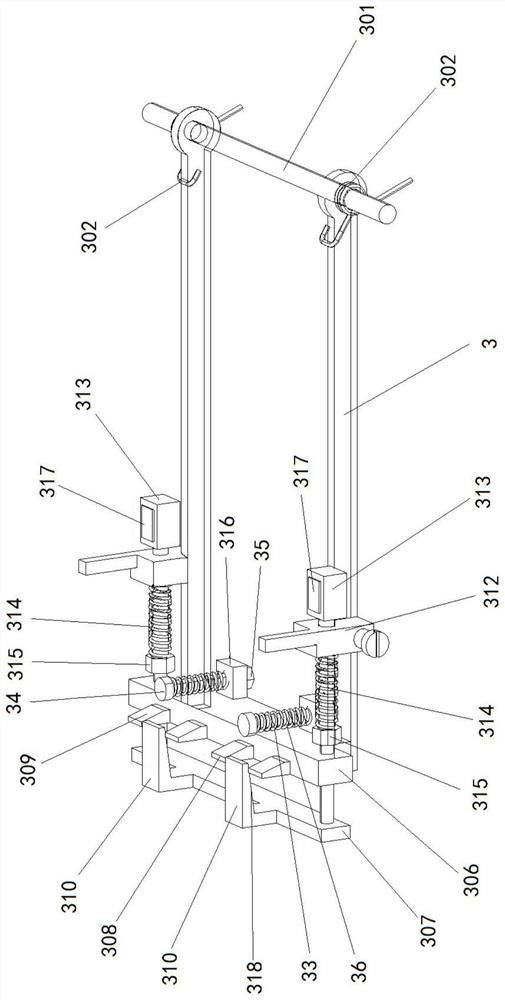

[0023] see figure 1 , a bag opening and closing mechanism on a new type of bagging machine, which includes a fork plate 2 arranged at the front end of the bagging machine and a pressing frame 3 arranged below the fork plate 2. The pressing frame 3 is far away from all One end of the fork plate 2 is hinged on the frame 1 of the bagging machine through the main shaft 301, and a torsion spring 302 is provided at the hinged position of the main shaft 301 and the pressing frame 3, and the torsion spring 302 drives the pressing The frame 3 is rotated downward to be separated from the fork plate 2; one end of the press-fit frame 3 close to the fork plate 2 is connected with a cable 303, and the other end of the cable 303 is connected after bypassing the guide wheel 304 to the output shaft of the motor 305, when the motor 305 rotates in the forward direction, it drives the pull cable 303 to shrink so as to move the pressing frame 3 toward the bottom of the fork plate 2, and when the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com