Centrifugal oat stir-frying device and stir-frying process

A centrifugal and control device technology, applied in the field of centrifugal oat frying device and frying process, can solve the problems of high labor intensity, overheating, poor taste, etc., achieve high degree of automation, reduce labor intensity, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and an embodiment.

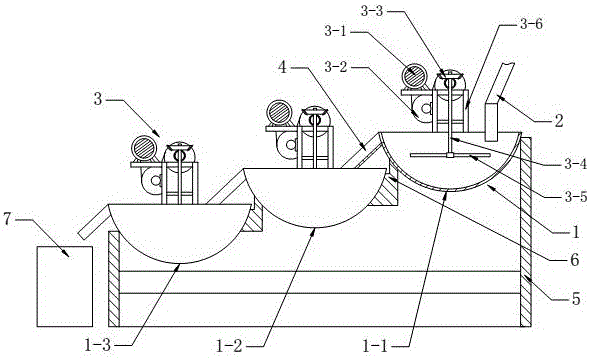

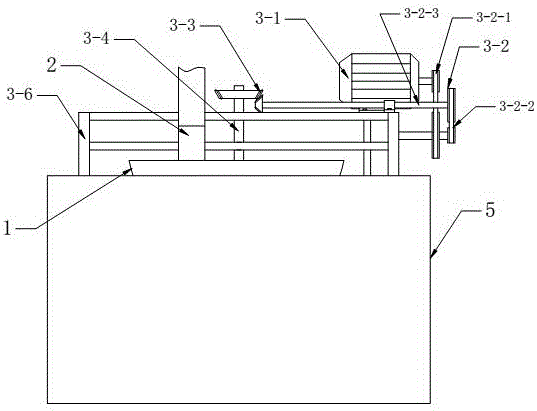

[0022] Such as figure 1 As shown, the centrifugal oat frying device in the present invention includes at least two fixed frying pans 1 in a stepped shape, and a rotating rotary device located on the upper part of each frying pan 1 for circumferentially stirring the oats in the frying pan 1. A stirring device 3 and a heating device 5 for heating the wok 1, a collection port 4 is provided between two adjacent woks 1, and the collection port 4 is for oats to enter the low position wok 1 from the high position wok 1 The passage of oats is provided with a conveying pipeline 2 of oats on the top of the frying pan 1 at the highest position.

[0023] The beneficial effect of the above-mentioned device is that: the device arranges the frying pans 1 in a stepped connection, and a rotary stirring device 3 for stirring the oat grains in the pot is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com