Atomizing core and manufacturing process thereof

A technology of atomizing core and microporous ceramics, which is applied in the fields of application, tobacco, and smoker’s supplies, and can solve the problems of container closure or complete closure, user’s health impact, and precipitation of harmful substances, etc., achieving low cost and strong versatility , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

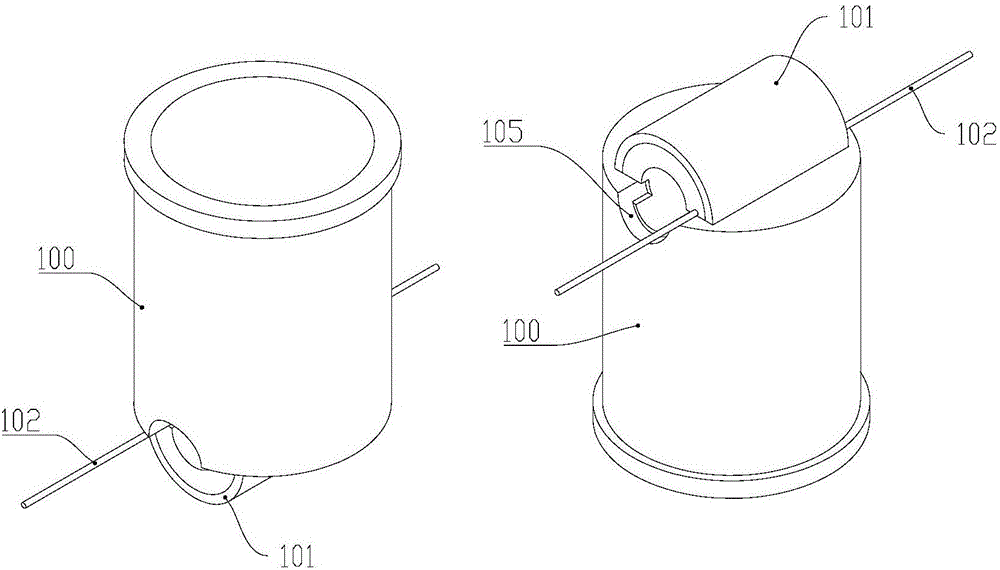

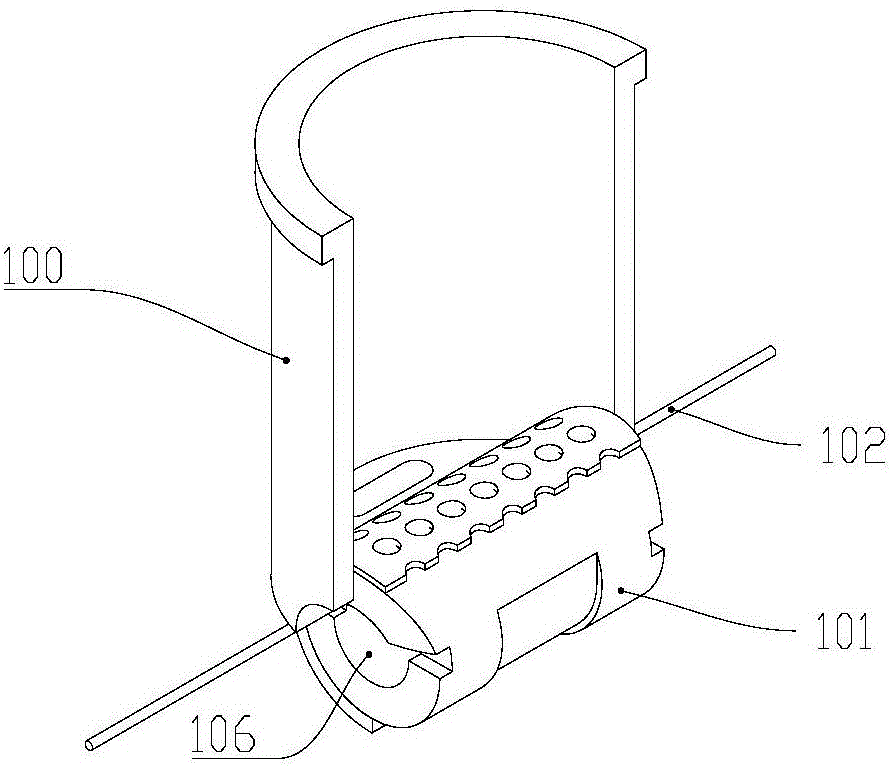

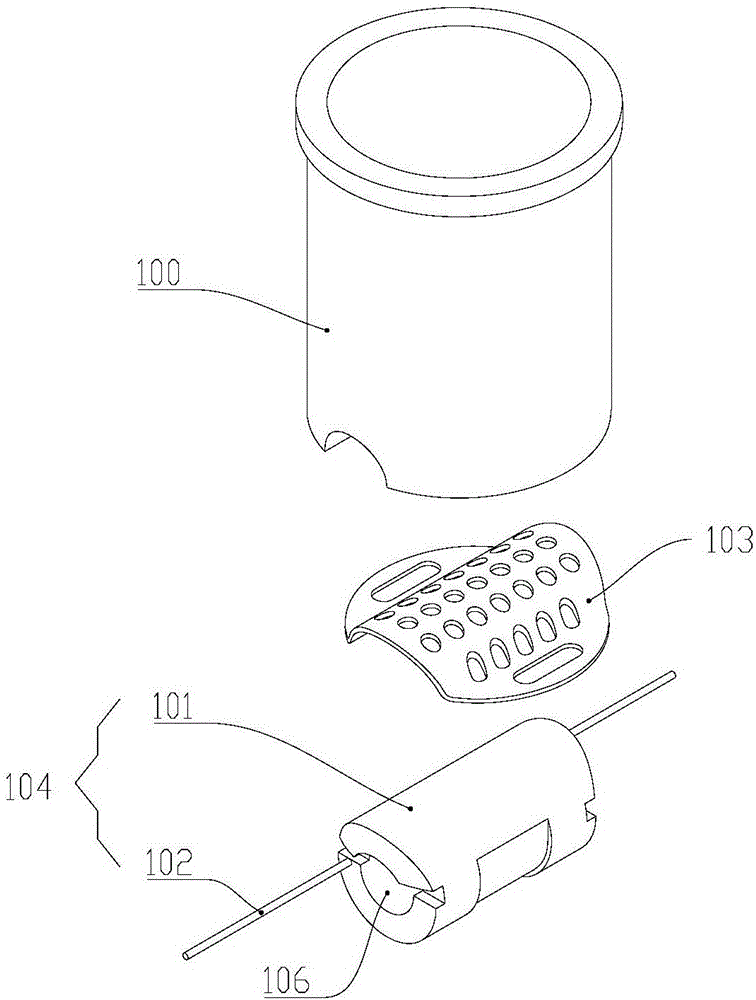

[0038] The first embodiment, such as Figure 1 to Figure 3 As shown, an atomizing core includes a ceramic barrel 100 for containing smoke oil or cream, and a heating body 104 that is sealed and connected to the lower end surface of the ceramic barrel 100. The heating body 104 includes a microporous ceramic body 101 and a microporous ceramic body 101. The heating wire 102 inside the porous ceramic body 101.

[0039] Specifically, the microporous ceramic body 101 is a cylindrical body structure. E-liquid or melted e-liquid can penetrate into the microporous ceramic body 101 . A pair of arc-shaped installation grooves 105 are symmetrically provided on the lower end sidewall of the ceramic barrel 100 , and the microporous ceramic body 101 is arranged laterally on the lower end surface of the ceramic barrel 100 , so that the volume of the atomizing core can be reduced. Both ends of the microporous ceramic body 101 are located in the installation groove 105 and are fixed and seale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com